Medical Wastewater Treatment System

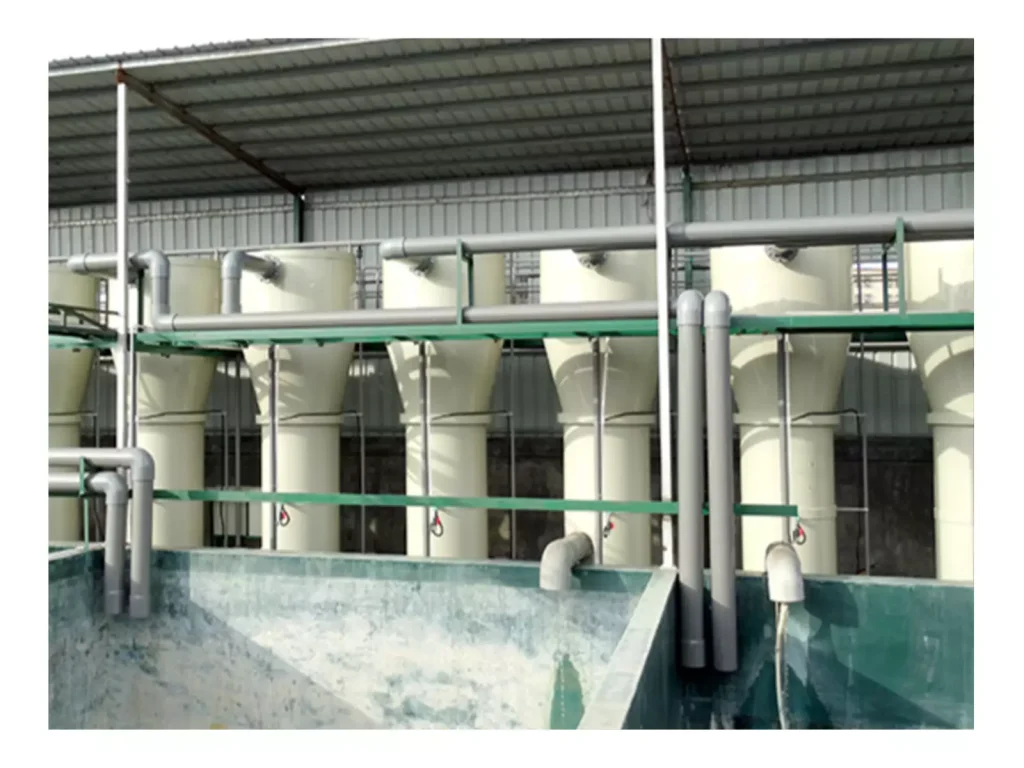

Molewater designs, manufactures and supplies Medical Wastewater Treatment Systems for hospital wastewater and medical institutional wastewater as safe discharge or reuse water, etc. Our Medical Wastewater Treatment Systems provide a cost-effective solution for treating and purifying medical wastewater by using advanced processes like pretreatment + biological treatment (AO/MBR) + deep disinfection (ozone/UV) + sludge disposal, customized according to the characteristics of medical wastewater and environmental discharge standards.

Molewater introduces professional customized Medical wastewater treatment technology solutions for you.

Share to

Pretreatment system

Removal of coarse impurities and water quality adjustment

Biochemical treatment system

Through microbial metabolism, remove pollutants such as COD, BOD₅, ammonia nitrogen (NH₃-N), total phosphorus (TP), etc.

Advanced Treatment System

Further ensure that the effluent meets discharge standards or reuse requirements.

Disinfection system

Kills pathogenic microorganisms such as bacteria, viruses, and parasite eggs.

Molewater is your most loyal partner

Molewater integrates advanced medical wastewater analysis and intelligent treatment technologies to precisely tackle complex contamination challenges, efficiently eliminating pathogens, chemical residues, and heavy metals to prevent environmental risks at the source. The fully automated system ensures compliance with strict medical discharge standards and reduces operational costs, suitable for hospitals, clinics, and research facilities. It delivers high-purity effluent for safe discharge or reuse, helping healthcare institutions achieve sustainable wastewater management and enhance their environmental stewardship.

Product Detail

Product Detail

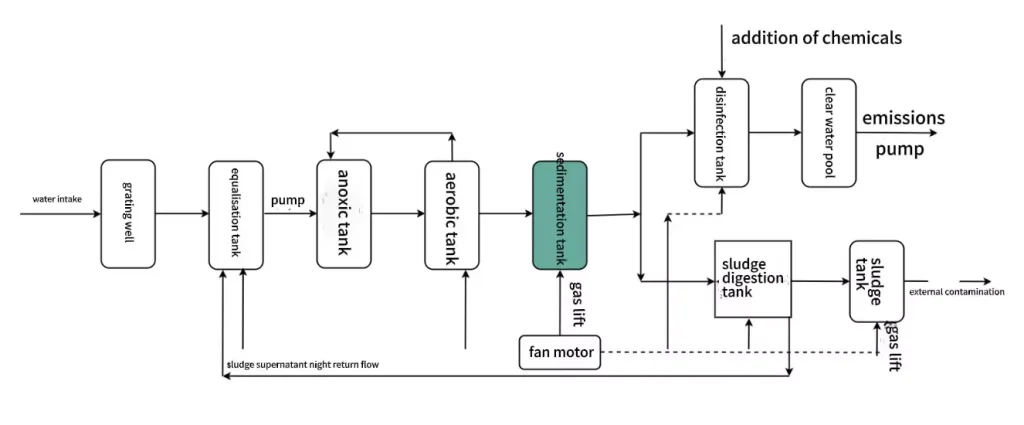

large particle suspended solids are first removed by pretreatment technology; then the water quality and quantity are balanced through a regulating tank. Subsequently, it enters the biological treatment stage, where the activated sludge method or membrane bioreactor (MBR) is used to degrade organic matter and remove pathogens. Next, advanced treatment is carried out to remove heavy metals and refractory pollutants by means of coagulation sedimentation and oxidation processes. Ultraviolet, sodium hypochlorite or ozone disinfection is then applied to kill residual pathogens. Finally, the sludge generated during the treatment process is concentrated, dewatered and harmlessly disposed of to ensure that the effluent meets the standards.

Related Parts

High-pressure Pump

High-pressure Pump Reverse Osmosis Membrane

Reverse Osmosis Membrane Dosage Device

Dosage Device UV Disinfector

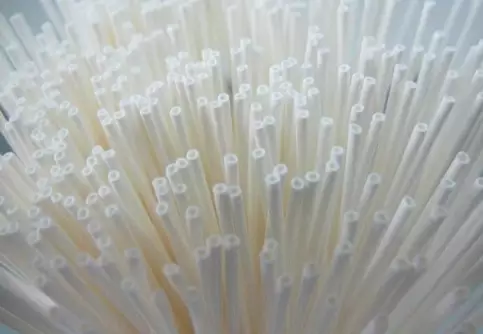

UV Disinfector Hollow Fibre Membrane

Hollow Fibre Membrane

Moore’s Objectives: A hundred years of doing one thing well.

Molewater owns an independent large-scale production workshop, enabling efficient control and full-process supervision of product manufacturing quality. We strictly adhere to standardized production processes and, with a sound quality assurance system, provide all cooperative projects with comprehensive and refined quality guarantees.

Molewater strictly ensures process execution compliance, leveraging a professional project installation team and robust management system to guarantee standardized and orderly construction environments.

Molewater ensures full-process product transportation safety, with packaging effectively mitigating damage risks during transit. The company has provided systematic equipment solutions to thousands of global enterprises, ensuring efficient product delivery and project advancement through professional services.

Get Free Quote

Please fill in the following form, we will respond your request in 24 hours.