Zero Liquid Discharge

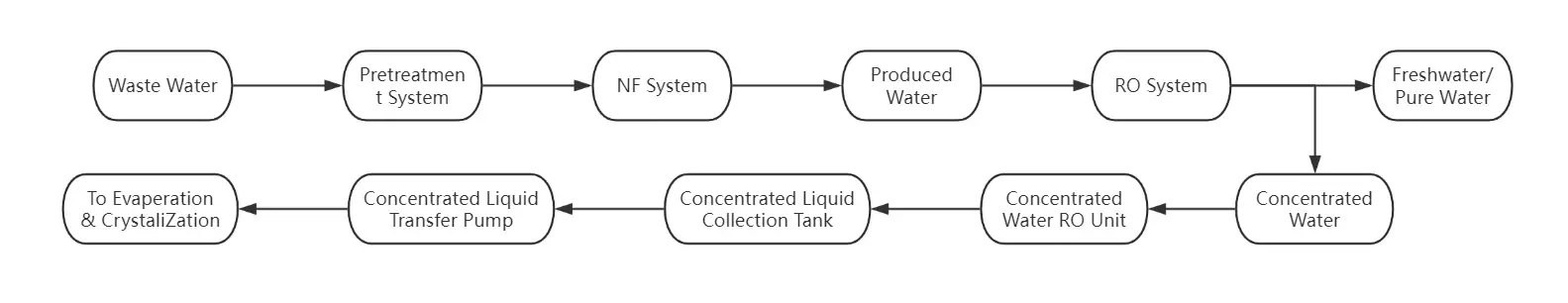

The zero liquid discharge system operates by recovering nearly all the water from industrial wastewater, leaving only solid waste to be disposed of or safely recycled. This process is a crucial part of zero liquid discharge wastewater treatment, where technologies like reverse osmosis (RO), membrane filtration, and evaporation are used to achieve maximum water recovery.

A zero liquid discharge plant typically includes several stages, such as pre-treatment, concentration, and evaporation, all working together to convert wastewater into reusable water.

Share to

As zero liquid discharge manufacturers and system suppliers, we are dedicated to providing reliable, efficient, and innovative ZLD systems

Membrane Concentration Technology

Membrane concentration technology is a concentration method based on membrane separation technology. Its core is the selective retention of target substances (e.g. proteins, sugars, salts, etc.) in the concentrate through the membrane’s.

Common membrane processes used for concentration include:

Reverse Osmosis (RO)

High-pressure membranes that remove water and retain dissolved ions, salts, and small organic molecules.

Nanofiltration (NF)

Suitable for partial salt retention and concentration of organic compounds, color, sugars, and small peptides.

Ultrafiltration (UF)

Concentrates macromolecules such as proteins, polysaccharides, and enzymes based on molecular size.

Forward Osmosis (FO) (emerging)

Uses osmotic pressure gradients instead of hydraulic pressure, reducing fouling and energy usage.

Treatment Process Flow

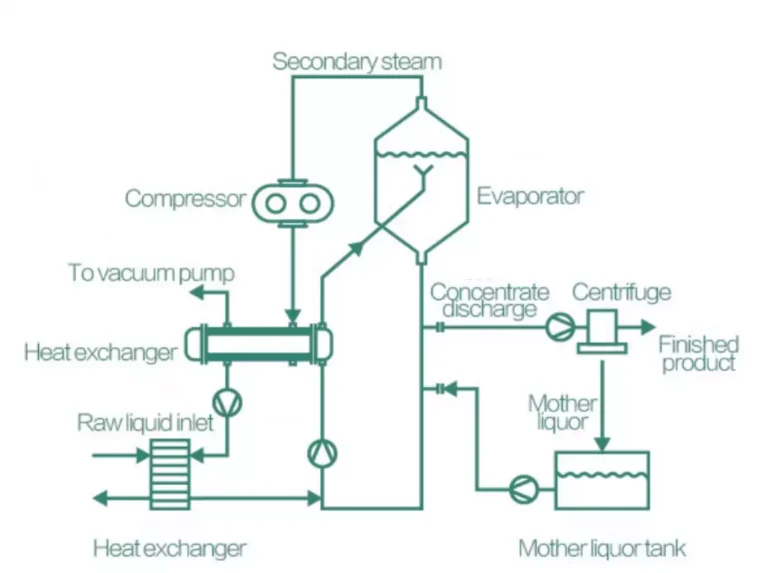

Mechanical Vapor Recompression (MVR) Evaporator

MVR (Mechanical Vapor Recompression) refers to the process of using a compressor to compress the secondary vapor generated during evaporation (such as distillation), which is low-temperature and low-pressure and otherwise unusable. By increasing its temperature and pressure, this vapor is reused as a heat source to heat the material that needs to be evaporated, thus achieving the purpose of recycling vapor.

Features

- 100% recycling of latent heat of secondary steam, completely avoiding the use of fresh steam, thus greatly reducing energy consumption

- The cancellation of the circulating cooling water, greatly reducing the cooling tower due to water consumption, power consumption, high maintenance costs of the problem

- For heat-sensitive materials can be used with a vacuum pump, can be done in a vacuum close to the absolute pressure, so as to achieve low-temperature evaporation, the lowest can reach 30 ° evaporation

- Compact structure, smooth operation, high degree of automation

- Initial investment is higher, but most of the project return on investment is also high, generally in 1.5 years to 2 years, up to 3 years

- Not suitable for brine solution boiling point rise particularly high materials (such as calcium chloride, magnesium chloride, caustic soda, etc.)

Treatment Process Flow

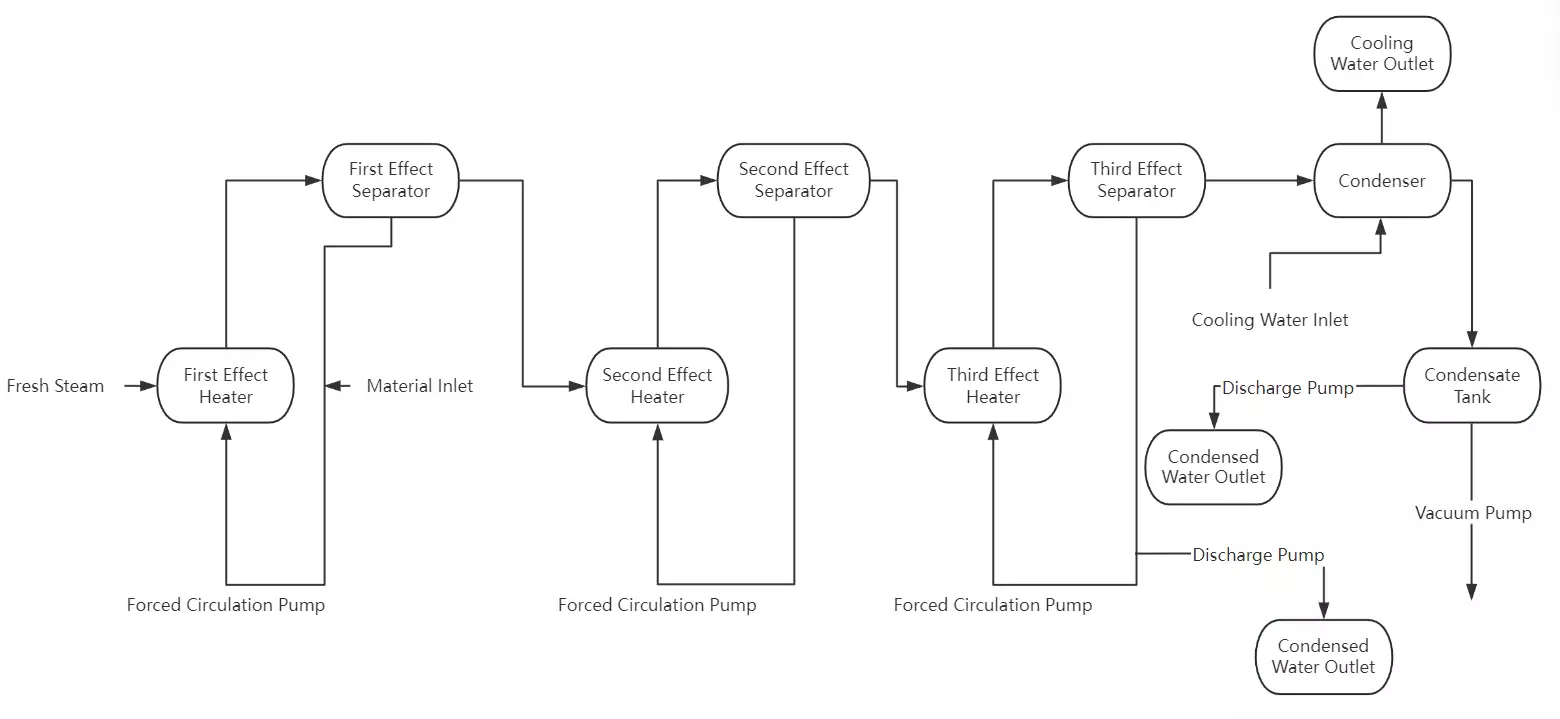

Multi-effect evaporator

Multi-effect evaporator is the heat transfer process, is more than one evaporator running in series evaporation operation, is the former effect of the secondary steam as the next effect of the heating steam of the tandem evaporation, so that the steam heat energy to be used many times, so as to improve the utilization rate of heat energy, multi-effect evaporation is mostly used in the treatment of aqueous solutions, is the process of boiling and condensation heat transfer. In the multi-effect evaporation, the operating pressure of each effect, the corresponding heating steam temperature and the boiling point of the solution is reduced once.

Features

- Wide application, strong applicability, especially for high salt, high COD difficult to deal with the class of wastewater

- Suitable for brine solution boiling point rise particularly high materials (such as calcium chloride, caustic soda, etc.)

- Operation flexibility, special adjustment range is large

- The need to continuously provide higher pressure of fresh heating steam

- The secondary steam from each effect needs condensation system condensation, requiring a large amount of cooling water circulation volume

Treatment Process Flow

Get Free Quote

Please fill in the following form, we will respond your request in 24 hours.