Nanofiltration For Drinking Water Treatment

High-quality, safe water is vital to daily industrial and personal life, and nanofiltration water treatment is now a dependable solution to satisfy this requirement. As a key technology, it is able to power both small-scale installations and larger projects, be it to improve nanofiltration in drinking water treatment to ensure potable water supplies and facilitating nanofiltration for water treatment in municipal and industrial situations.

Molewater has professional technical and R & D teams to manufacture nanofiltration drinking water equipment. Backed by our expertise in nanofiltration systems for water treatment, we treat customers from every corner of the world with professional and sincere services.

Share to

Molewater is always on the path of progress. By listening to customers’ needs and combining with objective realities, we continuously adjust and improve, and produce water treatment solutions that satisfy customers. We are full of confidence in the quality assurance and advantages of our products. Each piece of equipment is manufactured according to customers’ requirements. Before delivery, each module of the equipment will be debugged, and the equipment will be shipped only after no problems are found. Molewater is a reliable nanofiltration drinking water equipment manufacturer around you.

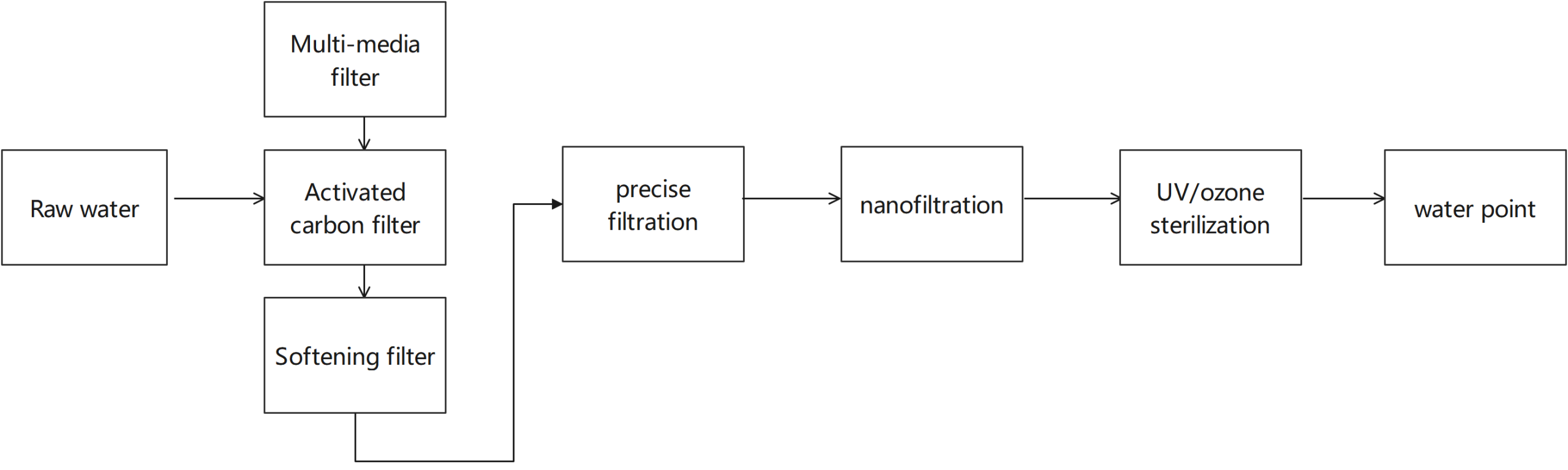

Process

Advantage

Traditional water treatment approaches have known drawbacks, so we’ve developed advanced drinking water solutions using molecular nanofiltration technology. Our solutions, featuring self – developed modular highly – integrated design, help customers obtain high – quality direct drinking water and deliver these benefits:

- Adopt multi – stage pre – treatment filtration to remove sediment, suspended solids, rust, odor, turbidity and chromaticity from tap water.

- Utilize internationally advanced nanofiltration membranes to target inorganic ions, organic molecules, microorganisms, bacteria and viruses, especially effectively removing divalent and higher – valent metal cations/anions, while smartly retaining some monovalent ions.

- Ensure health and safety of direct drinking water via combined UV and ozone sterilization, with monovalent ion retention rate over 55 – 95%.

- Offer modular design for smaller footprint, more reasonable structure and better quality assurance, plus real – time online monitoring of equipment and water quality.

We customize molecular nanofiltration – based water treatment solutions to meet strict quality standards, optimize system performance, and ensure reliable supply of safe direct drinking water.

Our Service

Molewater provides the most professional water treatment solutions.

Molewater offers a full-chain service covering every stage from inquiry to product commissioning, ensuring the provision of industry-specific water treatment products that fully meet customer needs.

- Program consultation

Molewater’s professional solution and technical department will provide you with an optimal solution based on your water issues, and will also draw process flow diagrams to help you understand the complete water treatment plan. - Technical guidance service

To ensure that overseas customers can properly operate their equipment, Molewater not only creates dedicated video installation tutorials for clients but also offers free online guidance services. - After-sales service

Molewater provides timely and professional after-sales service for every customer, ensuring that we will reply immediately within 24 hours upon seeing the message to address customers’ concerns.

Molewater is a leader in the water treatment industry

- Qualifications and certifications

Since its establishment in 2003, Molewater has obtained certifications including ISO9001, ISO14001, ISO45001, and CE. In the specialized medical industry, Molewater has also achieved certifications such as ISO13485, EAC, and ROHS. - Technical support

To provide customers with more comprehensive services, Molewater owns independently developed patented technologies, including those for delivery systems, control systems, and purification column inventions.

The five major processes for a product to be put into use

Analysis

We gain an in-depth understanding of all key information provided by customers, including details of the water source, water quality test reports, specific applications of the water, and water production index requirements, laying a precise foundation for the formulation of subsequent solutions.

Design

Our technical department will work closely with the design department to tailor solutions based on customers’ actual needs. This solution will not only accurately meet all the customers’ usage requirements, but also ensure high product quality while offering competitive pricing advantages, achieving the optimal balance of cost performance.

Production

We strictly adhere to safety standards in engineering design and meticulously refine every detail throughout the product manufacturing process, ensuring that the entire workflow—from design to production—is safe, reliable, and of exceptional quality.

Delivery

For products ready to be shipped, we conduct debugging on each module of the equipment. Once everything is confirmed to be in order, we record debugging videos and packaging videos before arranging shipment.

After-sales service

Within one year after the product is put into use, if there is a quality issue, we will provide you with free repair or replacement services. Meanwhile, we will also continuously offer professional online guidance and problem consultation support to fully ensure your usage experience.

Get Free Quote

Please fill in the following form, we will respond your request in 24 hours.