Semiconductors & Microelectronics

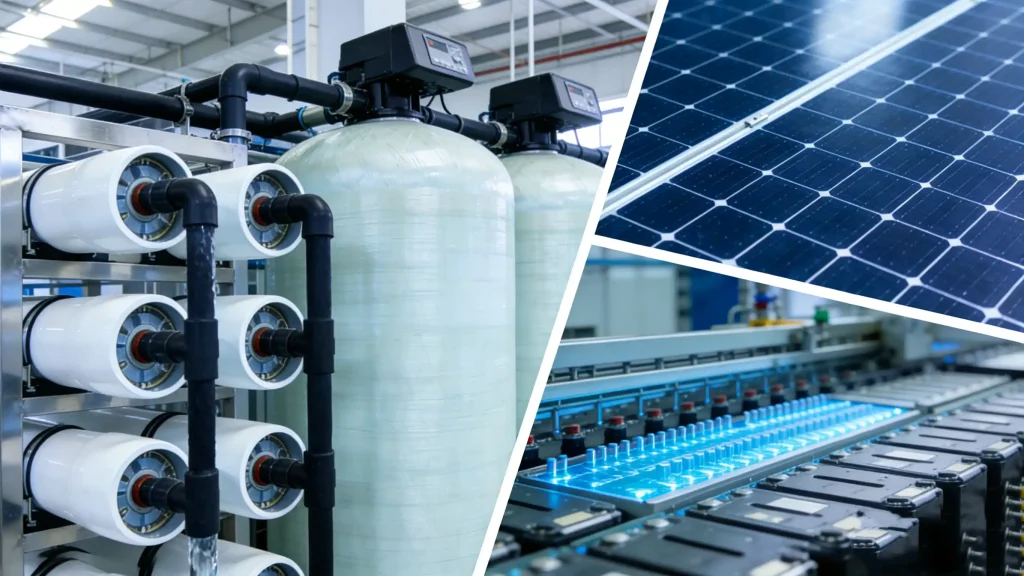

Molewater uses technology to provide worry-free water quality services for the innovation and sustainable development of emerging industries.

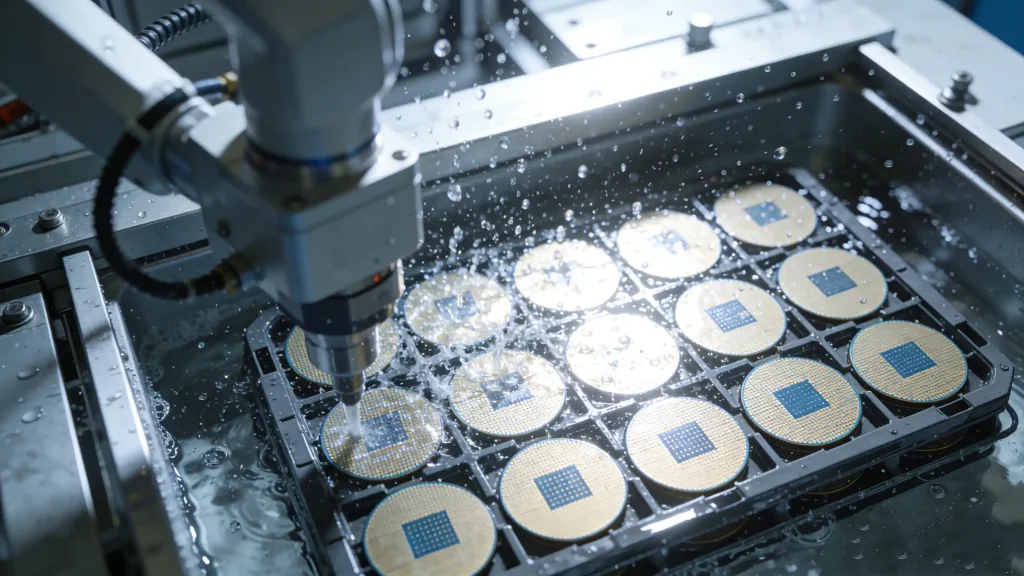

The manufacturing of semiconductor chips requires ultra-pure water with a stable resistivity of 18.2 MΩ·cm, and the tolerance for impurities such as TOC, particles, and metal ions is at the ppt level. Meanwhile, there are significant differences in water quality indicators among different process links (such as wafer cleaning and etching) and different products (such as 12-inch wafers and third-generation semiconductors), so the system must have dynamic adaptability

The electricity and water consumption for ultra – pure water preparation accounts for more than 20% of the total energy consumption of semiconductor factories. The water recovery rate of traditional systems is only 50% – 60%. Under the current “dual carbon” policy, enterprises are facing enormous pressure to save energy, reduce consumption, and control environmental protection costs.

Transforming Microelectronics Wastewater into Resources

Molewater Treatment provides cutting-edge ultrapure water technology and customized system services, deeply serving core fields such as semiconductors, microelectronics, photovoltaics, and new energy, and driving industrial technological upgrading and sustainable development with the power of purity.

Relevant Technologies

The system adopts a combined filtration process of multi-media filtration, activated carbon adsorption, softening, and precision filtration, which effectively protects the service life of the subsequent RO membrane and EDI module.

As the core purification process of the system, it can effectively remove more than 99% of dissolved salts, heavy metals, microorganisms, and endotoxins in water through membrane separation technology.

This technology combines electrodialysis and ion exchange, does not require acid-base regeneration, and is a core green process for preparing “high-purity water”.

Ultra-pure uniform particle resin can deeply remove trace ions and ensure that the terminal resistivity meets the standard.

Ultraviolet sterilization and 0.22 μm terminal sterilization filtration are used to control the risks of organic matter and microorganisms, and intercept micro-particles, colloids, and bacterial fragments to meet the water standard for ultra-pure water.

Maximizing Value in Every Drop

Beyond simple treatment, we provide the technical edge and regulatory peace of mind that allows you to focus on what you do best—manufacturing the future of technology. Explore All Services

Ensure Product Precision and Yield: Stably produce 18.2 MΩ·cm-level ultrapure water, strictly control ions, TOC, particles, and microorganisms, significantly reduce process defects in semiconductors, microelectronics, photovoltaics and new energy, improving product consistency and yield.

Improve Production Efficiency and Equipment Service Life: Realize fully automatic continuous water production, reduce shutdowns and manual intervention; The low-pollution and low-scaling design protects key equipment such as membranes, chips, batteries, and photovoltaic cells, extends their service life, and reduces maintenance costs.

Reduce Costs and Increase Efficiency:With a high water recovery rate (75% – 80%) and concentrated water reuse, water conservation is significantly achieved; EDI has no acid-base regeneration, intelligent flushing, and fault early warning functions, which reduce consumables, chemicals, labor, and energy consumption, and realize long-term cost reduction.

Compliance and Convenience:Full – process online monitoring (resistivity, TOC, pressure, flow, etc.) + automatic early warning + disinfection/antibacterial design ensure production safety, stable water quality, and environmental compliance, and avoid quality and safety risks.

Water Treatment Solutions For Semiconductors & Microelectronics

Ultrapure Water Solution for New Energy Power Batteries (Lithium-ion Batteries/ Sodium-ion Batteries/ Energy Storage)

Ultrapure Water Solution for Photovoltaics

Ultrapure Water Solution for Advanced Semiconductors/ Integrated Circuits

Ultrapure Water Solution for Hydrogen Energy Preparation

Ultrapure Water Solution for Quantum Computing/ Precision Optics/ Advanced Materials

Applications

New Energy Industry

- In the new energy industry, ultra – pure water systems can be applied in scenarios including but not limited to lithium – ion/sodium – ion battery electrode slurry preparation, electrolyte preparation, diaphragm cleaning, hydrogen energy PEM electrolysis raw water, and fuel cell humidification and cooling.

- In the power battery production line, the ultra – pure water system can remove metal ions and particles to avoid battery short circuits and thermal runaway; In green hydrogen production, ultra – pure water protects the electrolyzer proton membrane and catalyst, and can improve hydrogen production efficiency.

Advanced Manufacturing Industry

Ultrapure water systems can be applied in scenarios such as 12-inch wafer cleaning, advanced packaging CMP polishing, N-type photovoltaic wafer texturing, and MicroLED panel substrate cleaning. In semiconductor manufacturing, ultrapure water is used to remove ppt-level metal impurities on the wafer surface to ensure the yield of 7nm/5nm advanced processes. In the N-type photovoltaic production line, ultrapure water controls boron/phosphorus residues to improve photoelectric conversion efficiency.

Cutting-edge Scientific Research and High-end Materials

In the production scenarios of cutting-edge scientific research and high-end materials, the ultrapure water system is an important support for ensuring the accuracy and quality of R & D products. It can be applied in scenarios such as quantum device cleaning, superconducting material preparation, nano-material synthesis, and precision optical lens coating. In the field of quantum computing, ultrapure water needs to control TOC ≤ 1ppb and metal ions ≤ 0.001ppb to reduce the interference of impurities on the coherence of quantum bits; In the synthesis of nano-materials, ultrapure water ensures the uniformity and stability of material particle size.

Case Studies

15 Ton per Hour Semiconductor Ultrapure Water System in China

35 Ton per Hour Ultrapure Water System for China Spectrum New Materials

20 m³/h Solar-powered Ultrapure Water System in China

Other Industries

Request More Information

Contact Molewater for more information on available solutions.