Municipal Drinking Water Plant Upgrade

Confidently meet stringent standards, reduce chemical reliance, and automate operations. We provide the technology and remote expertise to transform your legacy plant.

Is Your Drinking Water Plant Facing These Pressures?

| Category | Specific Pressures |

| Variable Source Quality | Seasonal algae, turbidity spikes, or increasing natural organic matter (NOM). |

| Disinfection Byproduct (DBP) Concerns | Struggling to keep THMs and HAAs within new, lower limits. |

| High Operational Costs | Inefficient coagulation leading to high chemical and sludge handling costs. |

| Limited Trust in Legacy Processes | Reliance on aging filtration and disinfection systems with limited monitoring. |

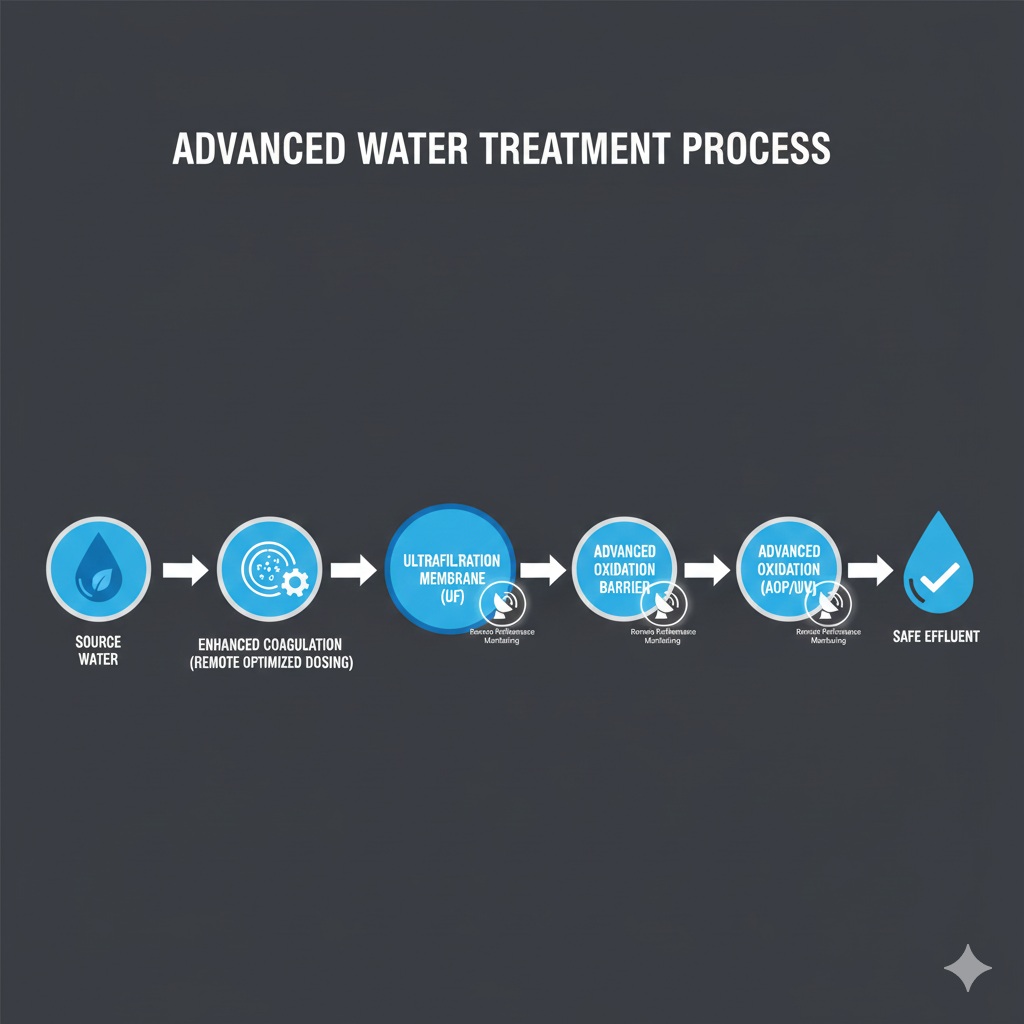

From Reactive to Proactive: A Multi-Barrier Approach, Remotely Supervised

Replace or augment sand filters with a membrane barrier that removes particles, bacteria, and protozoa with 100% efficiency, regardless of incoming turbidity.

>4-log virus removal | Turbidity < 0.1 NTU | Fully automated backwash.

Utilize UV-based or ozone-based AOP to target and destroy micro-pollutants, taste/odor compounds, and DBP precursors, reducing downstream chlorine demand.

Effective for pesticides & pharmaceuticals | Reduces chlorine demand by 20-40% | Compact footprint.

Remote Implementation + Tangible Benefits

Seamless Implementation, Wherever You Are

We manage the complexity remotely. Our team provides detailed design packages, conducts virtual Factory Acceptance Tests (FAT), and guides your local contractors through installation and commissioning via our secure collaboration platform. Post-commissioning, the Mole Cloud™ takes over for continuous optimization.

Quantifiable Results from Modernized Plants

| Compliance | 📊 100% consistent compliance with latest WHO/EPA-derived standards. |

| Cost Savings | 💰 20-35% reduction in coagulant and disinfectant consumption. |

| Operational Simplification | ⚙️ Up to 50% reduction in manual sampling and process adjustment tasks. |

| Reliability | 🛡️>99.5% plant availability with remote predictive maintenance. |

Request More Information

Contact Molewater for more information on available solutions.