1T Ultrapure Water Machine In Chongqing, China

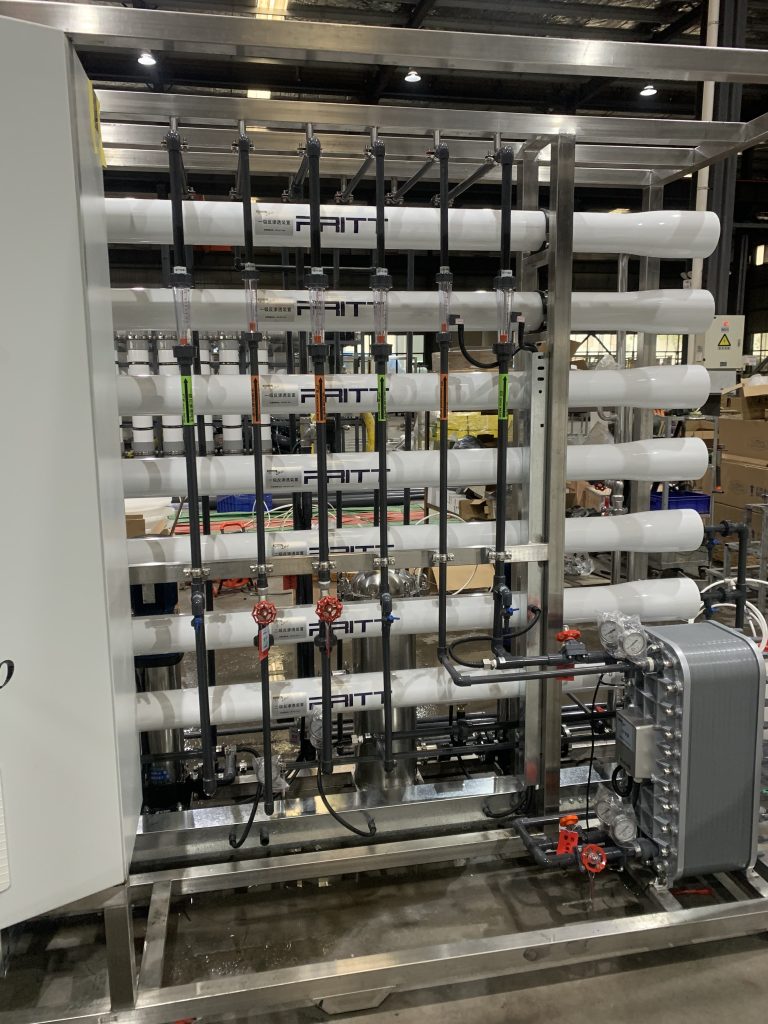

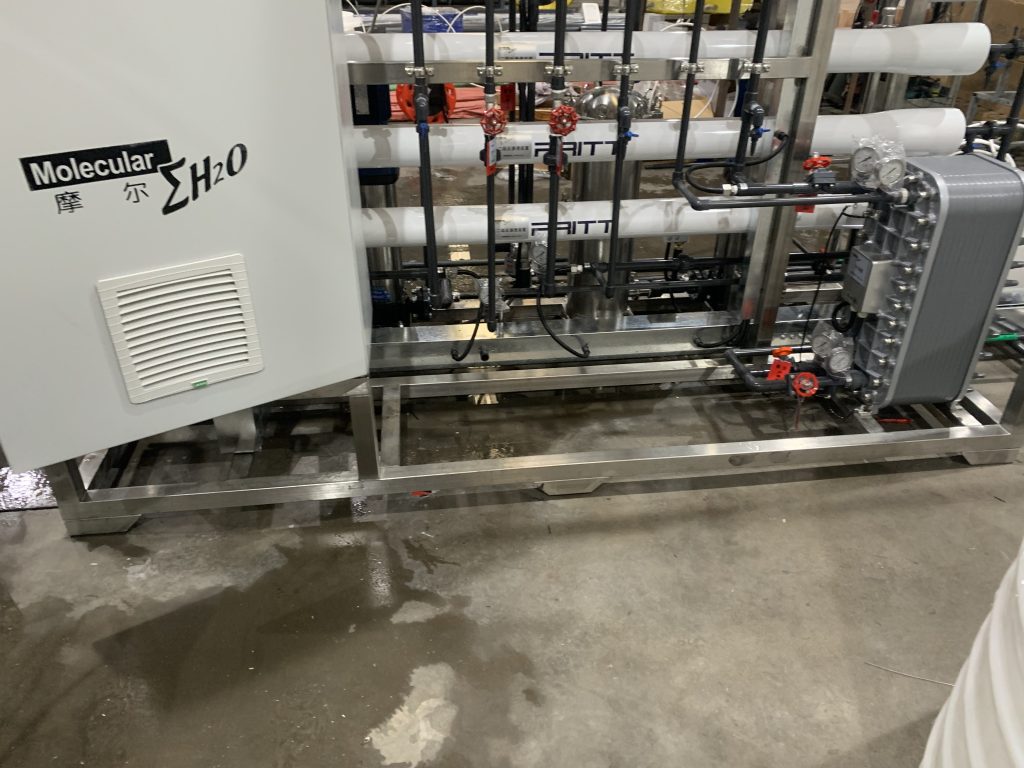

This 1T/H ultrapure water machine is a core water treatment device specially customized for high-end water usage scenarios in Chongqing, such as electronic component manufacturing, precision laboratory testing, and biomedicine research and development. It adopts the core process of “pretreatment + double-stage reverse osmosis (double-reverse) + EDI + polishing“, and uses UPVC material pipes and key components throughout the process. Efficiently remove various pollutants such as ions, organic matter, particles and microorganisms from raw water. The produced water quality can reach the electronic-grade ultrapure water standard with a resistivity of ≥18MΩ · cm and a TOC of ≤10ppb, precisely matching the strict water usage requirements of high-end R&D and production processes, helping enterprises improve product quality and R&D accuracy At the same time, it avoids the transportation costs and quality fluctuation risks of purchasing high-purity water from outside.

Pretreatment unit: This equipment is successively equipped with a multi-media filter to remove large particles such as sand and suspended solids from the raw water, an activated carbon filter to adsorb discoloration, odor, free chlorine and some small organic molecules, and a security filter to precisely intercept the remaining fine impurities, preventing damage to the subsequent membrane modules. The entire process adopts UPVC material pipelines, which are resistant to acid and alkali corrosion, preventing metal ions from dissolving and polluting water quality. At the same time, it is suitable for the characteristics of raw water quality in Chongqing area, laying a solid foundation for subsequent advanced treatment.

Core desalination module: This equipment adopts a two-stage reverse osmosis process as the core desalination unit. The first-stage reverse osmosis significantly reduces the TDS (Total Dissolved Solids) content of the raw water, removing most of the suspended solids, organic matter and ions. The second-stage reverse osmosis further purifies the water quality, ensuring the stability of the produced water and providing high-quality feed water for the advanced EDI treatment. The UPVC material pipeline has strong compatibility with the reverse osmosis system, effectively avoiding the impact of pipeline corrosion on the desalination effect.

Deep desalination unit: Utilizing EDI (Electro-deionization) technology, it deeply removes residual ions from the two-stage reverse osmosis product water without the need for chemical regeneration, enabling continuous and stable production of high-purity water. Coupled with the anti-pollution properties of UPVC material, it further enhances the operational stability of the system and reduces maintenance intervention.

Fine processing unit: It uses a polishing mixed bed to perform terminal purification on the EDI product water, precisely adsorbing the remaining trace ions, and ultimately producing electronic-grade ultrapure water. The UPVC material pipeline is free from secondary pollution throughout the process, ensuring the purity of the water quality produced at the terminal and meeting the ultimate water usage requirements for high-end research and development and production.

Core technological advantages

1. The water quality is of high and stable purity. It adopts a full-chain purification process of “pretreatment – double reverse -EDI- polishing”, with each unit complementing each other. The antigen water has strong fluctuation ability. Combined with the advantages of UPVC material in anti-pollution and no dissolution, the produced water quality always maintains electronic grade standards with minimal fluctuations, meeting the continuous water demand for precision research and development and high-end production.

2. The operation and maintenance are convenient and the cost is controllable. EDI technology does not require chemical agents for regeneration, significantly reducing the consumption of chemicals and the pressure of environmental protection treatment. UPVC material pipelines are corrosion-resistant, have a long service life, and reduce the frequency of equipment replacement. The entire system supports fully automatic operation, reducing the workload of manual operation and maintenance, and has a more advantageous long-term operating cost.

3. It has strong adaptability and is safe and environmentally friendly. The UPVC material meets the hygiene requirements for food-grade and industrial high-purity water treatment, with no risk of metal contamination. At the same time, it is suitable for different raw water quality conditions in Chongqing. The entire process does not discharge any harmful waste liquid, which is in line with the environmental protection concept of green production and research and development.