In the field of water treatment, selecting the appropriate filtration technique is essential to meet standards for quality of water and requirements for application. With the increasing demands for water quality and dual considerations for efficiency and costs in both municipal and industrial sectors, nanofiltration (NF) and reverse Osmosis (RO)–mainstream membrane technologies–are popular choices. But they differ in terms of filtration efficiency, practical scenarios, and prices. Blind selection risks resource waste from over-filtration or failure from under-filtration, making clarifying the right fit a core need for enterprises and individuals.

Differences Between Nanofiltration (NF) and Reverse Osmosis (RO)

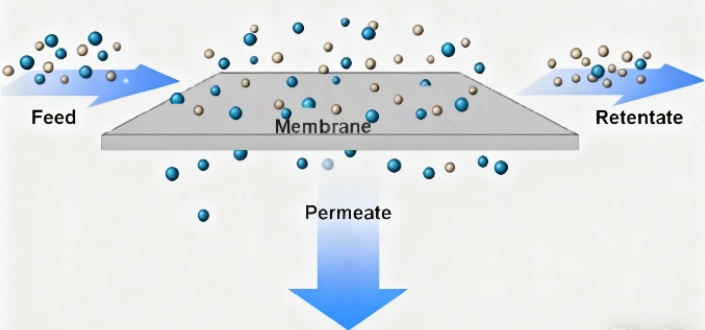

Both NF RO and RO are membrane separations driven by pressure techniques, which serve the main job of capturing water-borne impurities through semipermeable membranes. However, they differ essentially in filtration precision, operating conditions, and membrane properties–differences that directly define their application scopes.

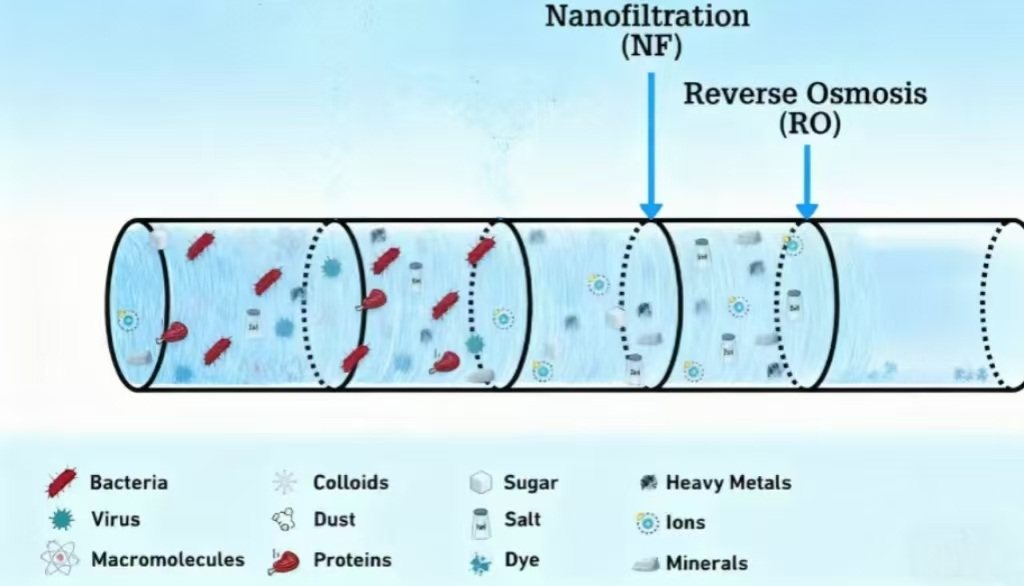

Filtration Precision

NF has an enlarged membrane pore of 0.001-0.01 millimeters, which acts as an “selective filtration” technology. It is able to effectively capture organics (e.g. antibiotics, pesticide residues) and divalent Ions (e.g. magnesium, calcium ions which decrease the water’s hardness) however, it has a lower retention rate (30%-50 percent) of monovalent Ions (e.g. sodium and chlorine ions). This permits NF to cleanse water, while also retaining essential minerals, thus which helps to avoid “over-purification”.

RO has smaller pores (0.0001 millimeters, which is 1/1,000,000 of the diameter of human hair) and acts as an “deep purification” technology. It can hold almost all ions (including heavy and monovalent ions) macromolecular organics as well as microorganisms (e.g. viruses, bacteria) with a retention capacity of greater than 99.9%. RO-treated water is very clean (“purified purified water”) however it is devoid of natural minerals such as magnesium and calcium.

Operating Pressure

NF operates at a lower the pressure (1-5 MPa) because its pores are larger and need less pressure force water through. RO requires a greater tension (2-10 MPa) to overcome higher the pressure of osmotic, resulting in a higher energy use.

Membrane Material Properties

Membranes of NF are typically charged (e.g. the sulfonated polyethersulfone membranes). Their surface charge is able to selectively capture divalent ions through “charge repulsion” (e.g. high retention rates of sodium and calcium ions). RO membranes are generally free of charge (e.g. the cellulose Acetate, the aromatic membranes of polyamide) and trap impurities through physical sieving that is not obvious to show the ion’s selectivity.

| Dimension | Nanofiltration (NF) | Reverse Osmosis (RO) |

| Filtration Precision | 0.001–0.01 μm, retains organics and divalent ions | 0.0001 μm, retains almost all ions and molecules |

| Operating Pressure | Lower (1–5 MPa) | Higher (2–10 MPa) |

| Membrane Material Characteristics | Charged membrane, selective retention of specific ions | Uncharged membrane, no selective retention |

In simple terms, NF is “precision screening” (removing harmful substances but conserving positive ones) and RO can be described as “comprehensive interception” (pursuing extreme pureness). These distinctions in technology provide the foundation for selecting the appropriate technology for various situations.

Click here to learn more about nanofiltration and reverse osmosis in water treatment.

Which Technology Fits Your Water Needs?

(1) Household Drinking Water Treatment

The most important demands for water treatment in households comprise “safety” and “health” by eliminating dangerous substances (e.g. residues of pesticides, heavy metals) without leading to excessive the filtration of minerals that are beneficial. This is all in keeping cost-effectiveness in the forefront of our minds.

Nanofiltration (NF) is a leader in this field, particularly for treating drinking water from the ground and taps of municipal sources, which has moderate hardness. It effectively catches heavy metals like lead and mercury, as also organics, such as disinfection byproducts (e.g. chloroform, e.g.) and antibiotics, which provide security. With a retention of 50 to 70% for calcium and magnesium Ions, it decreases the water’s hardness (minimizing the possibility of scaling) and also preserves the proper minerals. This is great for families with young or older children and helps to prevent mineral deficiencies due to pure water.

Reverse Osmosis (RO) suits households with severely polluted water (e.g., high-salt groundwater or industrial-contaminated areas). RO can provide deep desalination, as well as elimination of impurities in the situation that NF does not meet the standards, and provides highly pure water that is extremely pure. It is crucial to remember RO-filtered water doesn’t contain minerals, so it is essential to replenish calcium and magnesium through a healthy diet (milk and fruits). RO systems also require storage tanks (taking space) and have a 1:1-1:3 purified-to-wastewater ratio, consuming more water.

(2) Industrial Water Treatment

Industrial water requirements vary based on industry (food and beverages electronics pharmaceuticals and desalination) and define NF and RO’s distinct functions.

NF is extensively used in beverage and food processing, e.g., juice concentration and sugar purification. To concentrate juice, NF membranes trap macromolecules (sugars and flavorings) while allowing small impurities as well as water to pass through. This prevents loss of flavor or nutrients due to traditional heat concentration and requiring less energy consumption. In the pharmaceutical industry, NF purifies drug intermediates by eliminating organic impurities in the production of antibiotics, ensuring pureness without the addition of new contaminants.

RO is essential to meet the requirements of high purity for seawater desalination, brackish-water treatment and ultrapure water for electronic. Seawater (35,000 mg/L salt) requires RO to reduce salt levels to 500 mg/L (drinkable) which is utilized in more than 80 percent of the world’s desalination processes (e.g. the Saudi Arabian Jubail Plant). Chip manufacturing in electronics requires ultra-pure waters (resistivity >=18.2 MOcm) RO eliminates almost all microbes and ions, setting the foundation for further processes, and also preventing the occurrence of impurity-related problems.

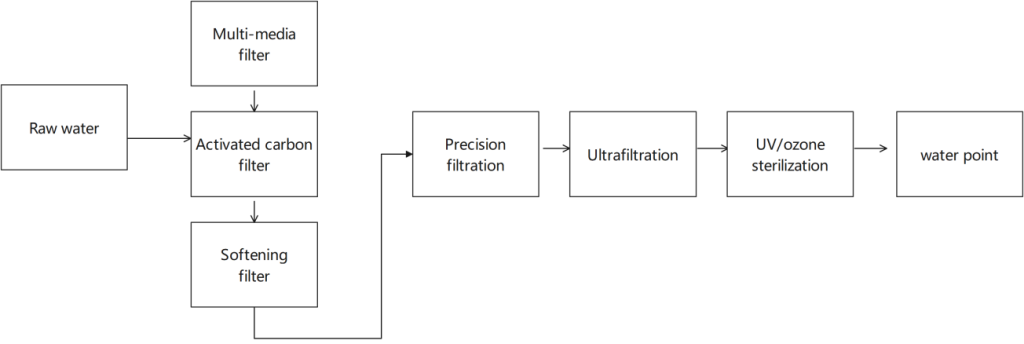

(3) Municipal & Environmental Water Treatment

The goals here include “wastewater recycling” and “ecological protection,” keeping in mind the efficiency, cost, and sustainability.

NF is utilized for advanced wastewater treatment specifically for municipal recycled water. After treatment with biochemicals municipal wastewater contains trace organics (antibiotics and Phthalates) that are not easily removed by conventional techniques; NF traps these, making reclaimed water ideal for landscaping or road maintenance. As an example the Beijing wastewater treatment plant using NF increased reuse rates from 30 percent to 50 percent which saved 1 million tons of fresh water each year.

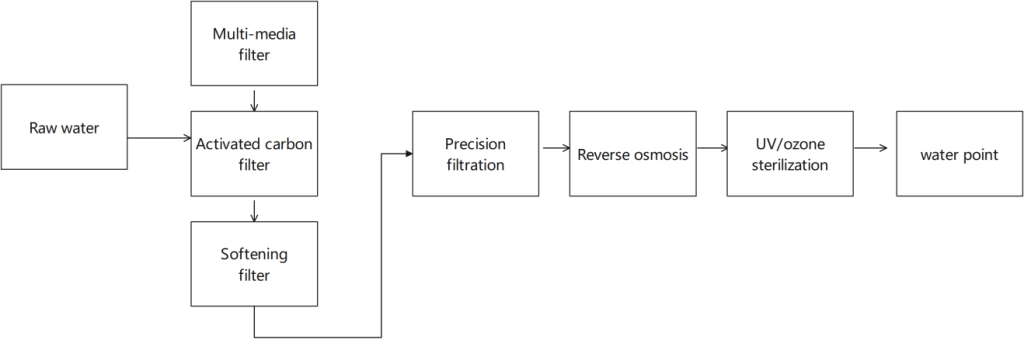

RO is a solution for water-scarce areas to the recycling of wastewater and high-concentration organic treatment of wastewater. The Singapore’s “NEWater” project uses “microfiltration + RO + UV disinfection” to treat industrial and municipal wastewater. RO eliminates more than 99.9% of pollutants creating water used for industrial cooling, landscaping as well as for partial drinking water use. In the printing and chemical industry, RO traps organics and salts in wastewater to recycle to reduce discharge and pressure on the environment.

Three Steps to Choose the Right Technology

Step 1: Clarify Water Quality Needs

Before deciding on a method begin by identifying two key elements of information obtained through water testing: 1. the nature and level of contaminants in the water supply (e.g. salt content and heavy metal content organic matter, etc.) 2.Water quality standards for the target area (e.g. drinking water has to meet the National Standard for Drinking Water Quality, and industrial ultrapure waters must be in compliance with the Electronic Grade Water Standard.

For municipal tap water that has the aim to provide “safety + mineral retention” when testing reveals only minor amounts of organics as well as residual chlorine (no significant salt levels) nanofiltration (NF) suffices. For groundwater with high salt levels or industrial wastewater that requires extensive desalination (e.g. reduction of the salt content from 3000 mg/L to less than 500 mg/L) reverse Osmosis (RO) is essential.

Step 2: Evaluate Application Scenarios

Scenarios vary in their tolerance for the effectiveness of treatment and cost:

Household use: If you have a lower everyday intake (10-20 L) and the focus is on healthy drinking water, choose the NF. If the water is extremely polluted and requires the highest purity, go for RO (with the mineral additive).

Industrial use: Select the NF option for juice concentration or purification of drugs (to keep the target components) Select RO in seawater desalination, or Ultrapure Water Production (needing the process of deep desalination).

Municipal use: Choose the NF option to reuse recycled water (e.g. the landscape water) to remove organic trace elements. Select RO for the recycling of water (e.g. the addition to drinking water) that needs the highest level of purification.

Step 3: Balance Costs and Benefits

With a limited budget and long-term needs (e.g. households). Prioritize NF because it’s a lower initial investment and operating expenses, resulting in greater value. For scenarios that require a lot of attention (e.g. electronics industry or seawater desalination) RO is essential even with higher cost, to prevent production losses due to low-quality water quality.

Also, consider “hidden costs”: RO’s discharges of wastewater could increase the costs of environmental treatment While NF’s lower energy consumption will reduce long-term electric bills. These elements must be considered as part of thorough evaluations.

Conclusion

NF and RO aren’t concerned with “which is more advanced” however “which fits better”. The primary benefit of NF lies in “selective filtration”-balancing the retention of minerals and purification, with a low energy consumption and costs, making it suitable for water purification in the home processing food, as well as municipal recycled water. RO’s primary benefit can be described as “deep purification”-achieving the highest purity (though more expensive and energy-intensive) vital for desalination of seawater and industrial ultrapure water and water treatment that is highly polluted. For your specific needs, come to Molewater to choose an RO Pure Water System or Nanofiltration For Drinking Water Treatment.