In the global effort to address water shortages and make sure that water is accessible in a safe manner, membrane filtration is now an essential element of modern water treatment. From drinking water to industrial wastewater, the method makes use of semi-permeable membranes to remove contaminants from water, and ensure efficiency and security that conventional methods such as sand filtration or chemical coagulation have been ineffective at achieving. What is the essence of membrane filtering? Why is it an integral part for water treatment system? This article explores the fundamentals of membrane filtration and its types, advantages and uses to address these vital questions.

Understanding Membrane Filtration Technology

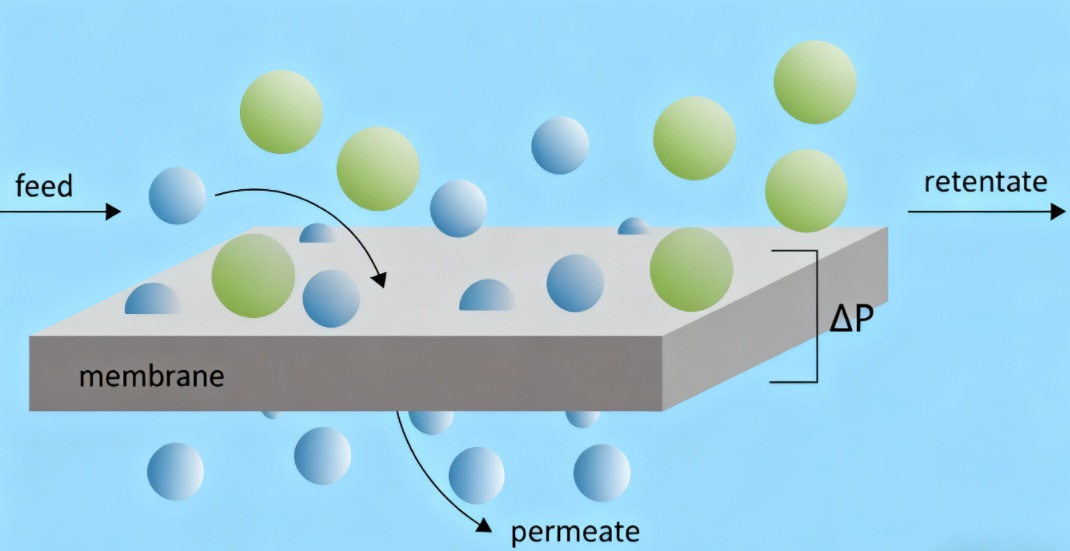

The process of membrane filtration used in water treatment utilizes semi-permeable membranes. These are porous and thin substances which allow water molecules to move through while also taking in impurities.

Contrary to conventional methods, membrane filtration requires less chemicals and produces less harmful effluent. It works by pressure: feedwater is pushed through the membrane. The later “permeate” (treated water) is gathered on one side while “concentrate” (trapped impurities) is removed or processed further. The efficiency and simplicity is ideal for small-scale installations such as your own home RO systems, as in large-scale installations such as municipal water systems.

Types of Membrane Filtration Processes

The four primary processes used in water treatment are reverse osmosis, nanofiltration, ultrafiltration, and microfiltration—often referred to as the “membrane spectrum” due to their overlapping capabilities.

Reverse Osmosis (RO)

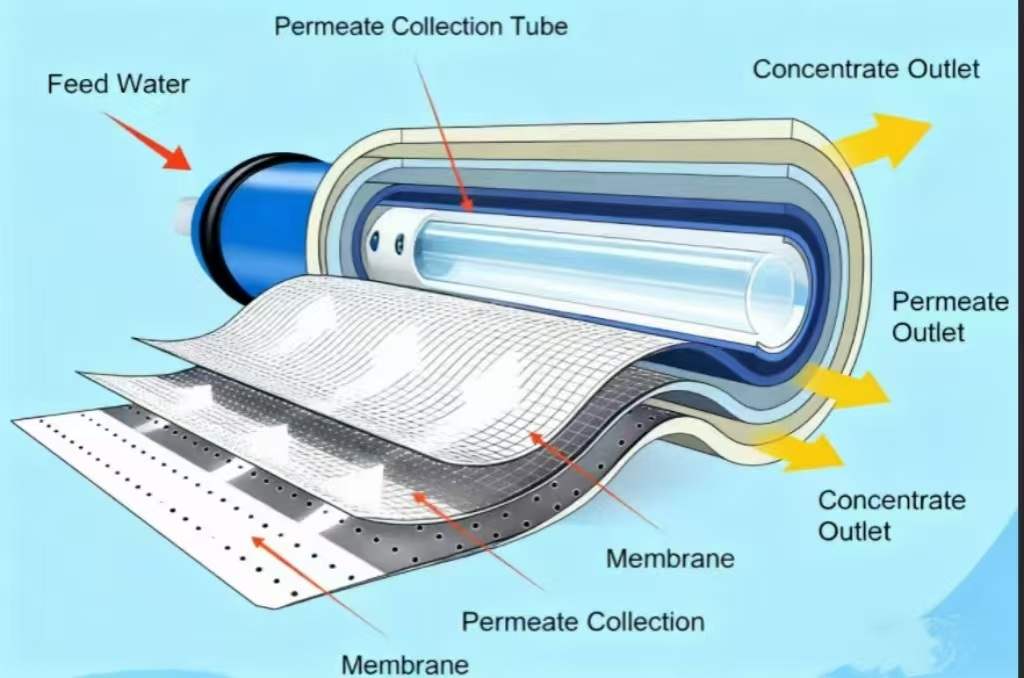

A highly precise technique for membrane filtering, Reverse Osmosis (RO) is a method of filtration that has extremely small pores, ranging from 0.0001 millimeters (1 nanometer) and even less than that of one virus. It operates in pressure (200-1000 pounds for every sq inch) to move feedwater across the membrane. It blocks the majority of the dissolved substances, such as heavy metals and salts (like arsenic and lead) and smaller organic compounds. RO is typically used to remove salt from brackish and seawater. It transforms salty waters into safe drinking water. RO also plays an essential role in the creation of ultra-pure water to manufacture electronics as well as for the production of pharmaceutical injections.

Nanofiltration (NF)

Nanofiltration (NF) is an impermeable system that can range from 0.001 and 0.01 micrometers. This is more than RO, but lower as ultrafiltration. It operates at a moderate tension (50-200 PSI) and can remove divalent ions (such as calcium and magnesium) and organic pollutants (like pesticides) and also monovalent ones (such as sodium) to pass through. This makes NF the perfect option for softening hard water to prevent the formation of scale on pipes and appliances. It is also employed to clean surface water by eliminating harmful substances and also to increase the utility of industrial water by reducing the amount of organic matter and salt in the water.

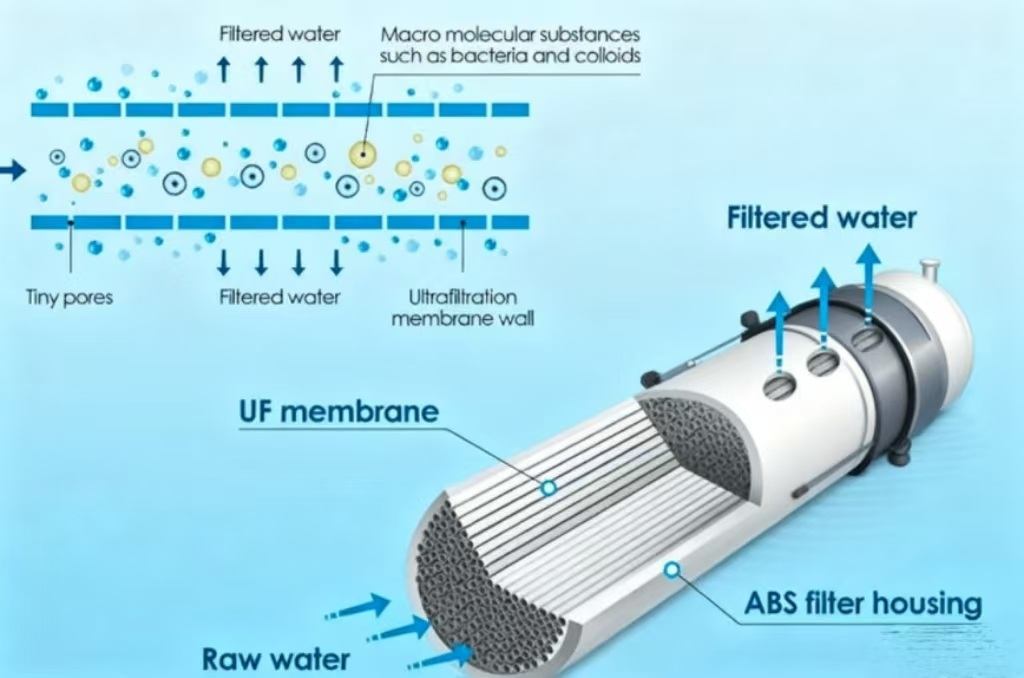

Ultrafiltration (UF)

Ultrafiltration (UF) has pores that range from 0.01 and 0.1 millimeters. They target colloids, bacteria (like E. coli) as well as viruses and other huge organic molecules. It works at a low tension (10-50 PSI) and is not able to eliminate dissolved salts, making it an economical method for the removal of microbial. UF is typically employed as a pretreatment for RO systems to guard RO membranes from being blocked with suspended particles. It also aids in the municipal water system, which helps rid the water of pathogens as well as provide water purification to rural communities by means of portable devices.

Microfiltration (MF)

Microfiltration (MF) is the one with the biggest pores of the four types, and ranges between 0.1 up to 10 micrometers. It operates at a very small tension (5-30 PSI) and is primarily used to remove floating solids and sediments algae, as well as large amounts of bacteria. MF is typically utilized as a first stage in water processing. It assists in pretreating wastewater prior to RO or NF to lessen particle burden, clears surface water used in industry cooling, as well as purifies aquaculture water by eliminating excess feed and waste from fish.

Key Benefits of Membrane Filtration

Membrane filtration offers distinct advantages over traditional techniques of treatment for water. That is the reason why it is now a top option for policymakers and engineers:

High Efficacy in Removing Contaminant: It is the type of membrane you select can remove as much as 99.9 per cent of harmful pathogens, such as viruses and bacteria, organic pollutants, which is far more than the capabilities of chlorination or sand filtering on its own.

Use of Chemicals at A Minimum: Contrary to the processes of coagulation and dissolution (which depend on alum, chlorine and various chemical substances) membrane filtration makes use of the physical process of separation. This lowers the cost of chemical usage and also eliminating harmful byproducts such as trihalomethanes, which are produced by chlorine and makes water safe to drink.

Small Design: Membrane systems need less space than traditional treatment plants, which makes them perfect for urban areas or in remote areas with limited space.

Continuous Performance: Membranes create a steady permeate, with excellent quality regardless of the water’s quality. This is essential to ensure that the quality of water is in compliance with strict guidelines like EPA guidelines for drinking water.

Applications of Membrane Filtration in Water Treatment

Drinking Water Treatment

Membrane filtering is crucial for the safe drinking of water, by removing pathogens organic pollutants, as well as harmful contaminants. Ultrafiltration (UF) is commonly utilized by municipal water systems in order to get rid of the presence of bacteria (like E. coli) and viruses. Reverse Osmosis (RO) is a solution for high-salt or brackish water in the coastal or desert regions. RO or portable UF devices can also be used to treat rural areas that are not served by central treatment, allowing on-site water purification for well or river water, and decreasing the risk of waterborne illnesses like the cholera.

Wastewater Treatment

It plays an essential role in recycling wastewater, transforming recycled water into reused resources. Municipal wastewater is treated with the process of Microfiltration (MF) as well as UF following biological treatment to eliminate all remaining solids and pathogens. making reclaimed water suitable to use for irrigation, park maintenance or industrial cooling. For industrial wastewater, nanofiltration or RO cleans effluents from the electroplating, textile and food processing industries by recovering important materials (like the metals) and reducing the discharge of pollutants into water bodies that are naturally aquifers.

Industrial Process Water

Industries depend on membrane filtration to meet the strictest water purity requirements to produce. Power plants utilize RO, or NF in order to clean the boiler’s feedwater by removing the minerals that contribute to scale buildup and increase efficiency in energy use. Electronics manufacturing uses RO together with UF to create ultra-pure water (UPW) to clean chips and ensure that no impurities impact the quality of microchips. Food and beverage facilities utilize MF to clean the water used in processing, ensuring product quality and safety.

Pharmaceutical Water Treatment

The industry of pharmaceuticals requires the purest water and membrane filters are crucial to this. RO as well as UF systems create pure water which can be used to create pharmaceuticals. It also removes endotoxins, bacteria, as well as dissolving solids. For injectable drugs, RO or other distillation techniques produce “water for injection” (WFI) that is compliant with global guidelines (like FDA and EU GMP). This assures that the drugs are safe and efficient because tiny imperfections can cause the effectiveness of the medicine to decrease.

Final Thoughts

Membrane filtration has revolutionized the process of water treatment by providing a scalable environmentally-friendly, effective, and efficient solution to tackle global water problems. From tiny pores of RO membranes that serve for desalinating seawater, to the larger pores in MF to clean of water. Each step serves a distinct purpose and demonstrates its versatility to be used for water purification, industrial wastewater pharmaceutical, as well as other uses.