In pure water systems, Reverse Osmosis (RO) membranes form their “core heart,” with their performance directly influencing the quality of water and operational efficiency and maintenance costs. Used across industrial production, laboratories, and pharmaceuticals, they enable deep desalination and impurity retention–high-quality RO membranes account for 30%-50% of total maintenance costs, even higher for large industrial setups.

However, many people focus on membrane manufacturers or system specifications, ignoring the crucial aspect of pre-treatment. The data shows that 80% of RO problems are caused by poor pre-treatment. Sludge and residual chlorine, microbes and hardness ions can cause irreparable damage, reducing lifespan and maximizing energy consumption and increasing the risk of production stopping. Pre-treatment is not an optional feature but is a fundamental requirement to ensure stable RO operation and cost reduction.

What Happens to RO Membranes Without Pre-Treatment?

Membrane Fouling

Raw water contains suspended solids (sediment, rust and clay) and colloids (proteins and humic substances). Though small in size, these impurities attach directly to RO membranes without pretreatment and form dense contaminant layers which clog pores reducing flux (water production per unit time) by 20%-40% within one to two months – necessitating increased energy costs as systems must raise operating pressure to maintain output, increasing operating costs significantly and hastening membrane wear. Unresolved fouling penetrates membranes making chemical cleaning unattainable requiring early replacement or early replacement by chemical cleaning agents and necessitates system upgrade or upgrade in order for them to function effectively.

Membrane Scaling

Most raw water contains calcium and magnesium ions (“water hardness”). When filtering with RO, water passes through while these hardness ions concentrate on the reject side. When they exceed solubility limits, they bind with carbonate/sulfate ions to form insoluble scales such as calcium carbonate. These highly rigid scales adhere tightly, infiltrating micropores to cause fouling and damage the separation layer–resulting in permanent 10-15% decrease of desalination rate while severe scaling cannot be reversed with descaling agents leading to complete membrane failure.

Membrane Oxidation

The process of water disinfection can leave some residual chlorine in water sources. RO membranes made of polyamide are highly vulnerable to contamination. on contact, chlorine causes polymer chains to break down within polyamide, expanding pores and reducing separation efficiency which can lead to TDS levels that are higher than norms by 50%, making water inequivalent for drinking purposes. Unfortunately, oxidation damage can’t be reversed. Therefore, replacement of membranes could be the only option that is long-lasting.

Biological Contamination

Bacteria, algae and fungi that thrive under favorable temperatures/humidities quickly multiply on membranes under ideal conditions, secreting viscous metabolites which combine with impurities to form dense biofilms which block pores while acidic byproducts damage membranes prematurely aging them over time. Traditional chemical cleaning alone cannot remove biofilms effectively requiring additional costly pre-treatment or even special biocides as standard cleaning ineffective against them requiring three or five times more frequent cleaning sessions without pre-treatment measures or pre-treating them beforehand.

How Does Pretreatment Protect Reverse Osmosis Membranes?

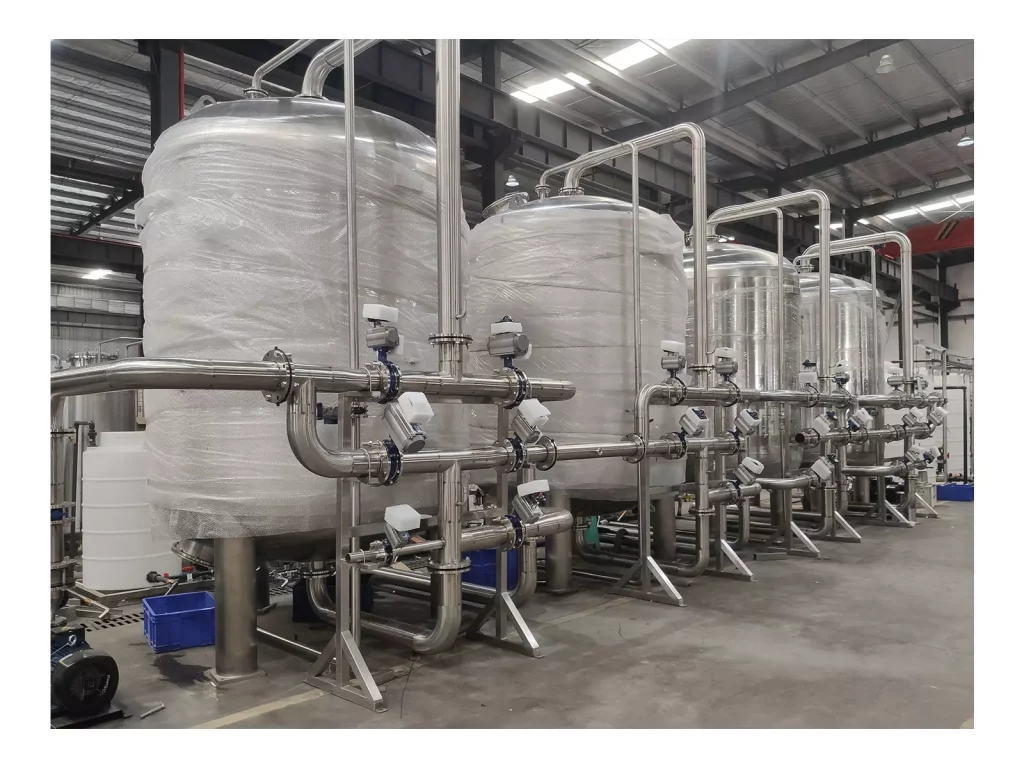

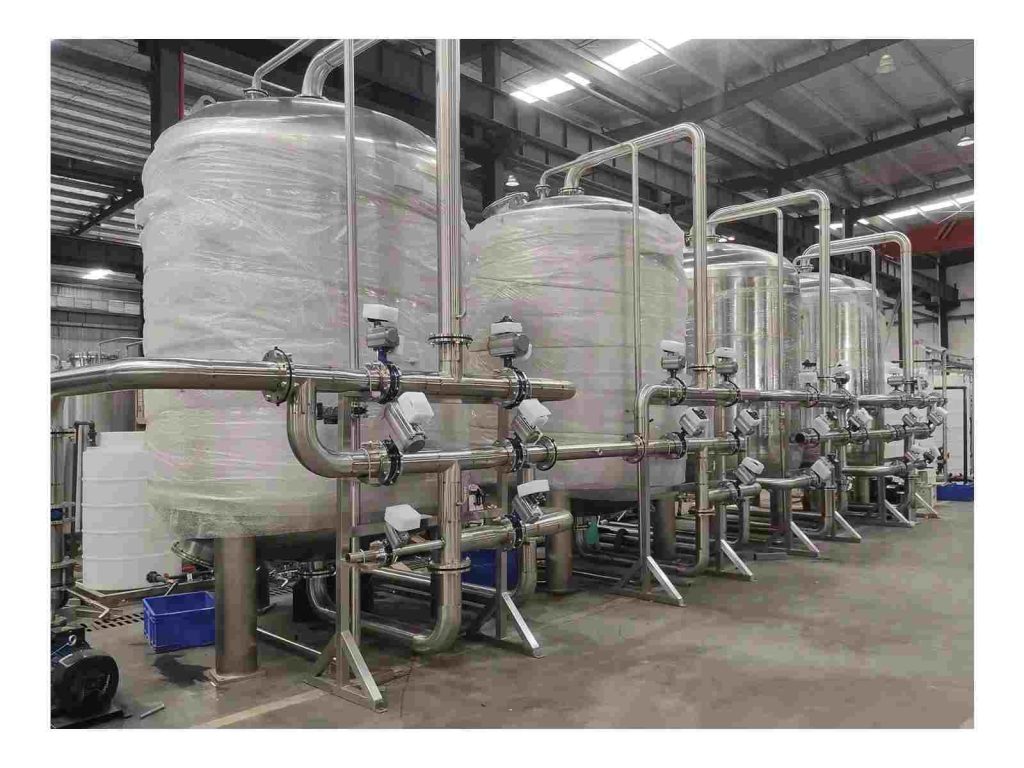

Multi–media Filters

Multi-media filters serve as an early line of defense against particles in water by employing graded filter media (quartz sand, anthracite or manganese sand) designed to trap large impurities while smaller particles catch fine impurities. Quartz sand captures sediment and rust; anthracite absorbs organics and fine particles with its large specific surface area; while manganese sand removes iron and manganese ions. Post-treatment, over 90% of suspended solids are eliminated, water turbidity decreases to below 1 NTU and SDI (Silt Density Index) is kept below 5, thereby effectively preventing RO membrane fouling. With its backwashing function and regular flushing function, trapped contaminants are flushed away reliably, guaranteeing reliable filter performance.

Activated Carbon Filters

Activated carbon filters serve as an essential defence against RO membrane oxidation, typically using coconut shell activated carbon with a porous structure (specific surface area: 500-1500 m²/g) and strong adsorption capacity to remove over 99% of residual chlorine and protect polyamide membrane from further oxidative damage. Furthermore, activated carbon filters adsorb humus, pesticide residues, odors and pigments by 40%-60% thus further protecting membrane from further organic fouling while prolonging cleaning intervals further. Saturated activated carbon must be replaced promptly so as not to allow further pollution of secondary pollution of either type.

Softening Resins for Reducing Hardness Ions

Softening resin systems provide the core solution to RO membrane scaling by employing sodium-based cation exchange resins. As raw water flows through, calcium and magnesium ions (the primary cause of water hardness) are adsorbed while sodium ions are released via ion exchange, effectively reducing hardness levels to below 0.03mmol/L post treatment; eliminating scale formation on RO membrane’s concentrate side and providing cost effectiveness through regeneration using salt for repeated uses over multiple cycles extending RO membrane lifespan significantly over time. For high hardness raw water (e.g. groundwater), softening resins are indispensable in prolonging membrane lifespan by providing cost effective softening solutions which extend RO membrane lifespan significantly beyond any previous methods used alone.

Economic Benefits of Effective Pretreatment

Extending RO Membrane Lifespan

Scientific pretreatment extends RO membrane lifespan by 3 or 4 years or longer for small- to medium-size pure water systems; replacing RO membranes costs $2,000-$5,000 on these systems; increasing lifespan by 2-3 years can save thousands in replacement costs alone! For larger industrial systems with higher replacement costs, such as those found at hospitals and waste treatment plants, the savings become even greater; extended membrane longevity also lowers labor expenses associated with replacements as well as equipment downtime, further decreasing overall operational expenses.

Reduce Maintenance and Cleaning Costs

Systems without pretreatment require regular chemical cleaning to remove fouling and scaling; effective pretreatment reduces this frequency to once every 6-8 months or longer. Chemical cleaning involves incurring costs for agents such as citric acid, sodium hydroxide as well as labor; when done without pretreatment it costs an average of 30-40% more in cleaning agents and labor without significantly lessening production disruption during this process. According to statistics effective pretreatment can save both money and production disruption losses during cleaning processes – saving both costs in cleaning agents while minimizing production disruption losses caused during chemical cleaning operations.

Enhancing System Uptime and Water Production Efficiency

A proper pretreatment can drastically reduce RO membrane failures and breakdown rates of equipment, increasing the system’s uptime by 5% to 10 percentage. For businesses that require constant drinking water, this leads to increased productivity and reliable product quality. Stable pretreatment ensures constant flow of the membrane and output of water which prevents decreases caused by scaling or fouling. This guarantees a continuous pure water supply for production as well as research, preventing any delays to production schedules and creating more economic value.

In the End

Pretreatment is pure water equipment’s “first line of defense”—a core prerequisite for stable RO membrane operation and lower costs, whose importance cannot be overstated. Far from an “extra expense,” it’s a high-return “cost-saving investment”: via multimedia filtration, activated carbon adsorption, softening, and precision filtration, it blocks raw water contaminants, preventing membrane fouling, scaling, oxidation, and biological damage to extend lifespan, cut maintenance costs, and boost efficiency. For reliable industrial solutions, recommend Molewater’s pretreatment filters — professional, tailored for RO systems, ensuring consistent purification.