In contemporary research, water is among the most often employed reagent, yet its high quality is often omitted. From sophisticated analytical methods like HPLC or ICP-MS and delicate cell cultivation techniques ,the presence of tiny impurities could impede years of work. The achievement of ultrapure water with a resistance at 18.2 MΩ.cm requires a sophisticated purification process that has multiple stages that removes organics, ions, bacteria and other particulates.

We examine the key technology, selection criteria and maintenance methods for water systems in laboratories to ensure that your laboratory consistently produces reliable, repeatable, and precise results every single day.

What is Ultrapure Water?

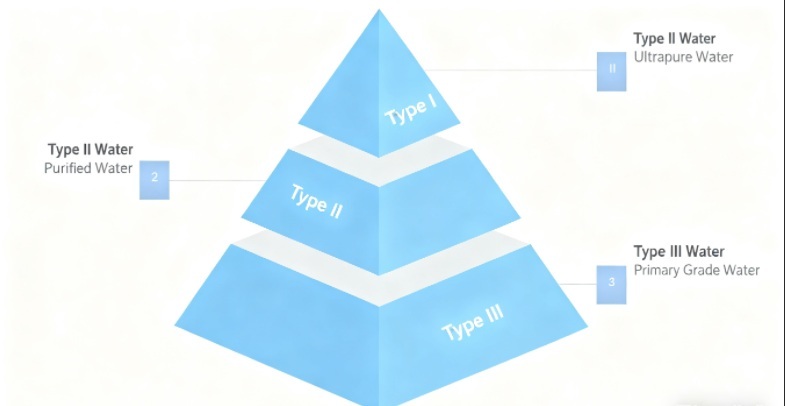

It is not the case that all “pure” water is created to be the same. To ensure consistency across the globe the organizations such as ASTM (American Society for Testing and Materials) and ISO have separated lab water into distinct categories. Knowing these levels can be the very first thing towards finding out how to obtain the appropriate water for your needs.

| Feature | Type III (RO Water) | Type II (Pure Water) | Type I (Ultrapure Water) |

| Resistivity (25°C) | > 0.05 MΩ.cm | > 1.0 MΩ.cm | 18.2 MΩ.cm |

| Total Organic Carbon (TOC) | < 200 ppb | < 50 ppb | < 5 ppb |

| Bacteria (CFU/ml) | < 100 | < 10 | < 1 |

| Typical Applications | Glassware rinsing, filling autoclaves | Buffer preparation, general chemistry | HPLC, ICP-MS, PCR, Cell Culture |

For laboratories that require precision, Type I Ultrapure Water is the gold standard. It is almost free of minerals that are dissolved as well as gases and organic compounds.

How Ultrapure Water is Produced ?

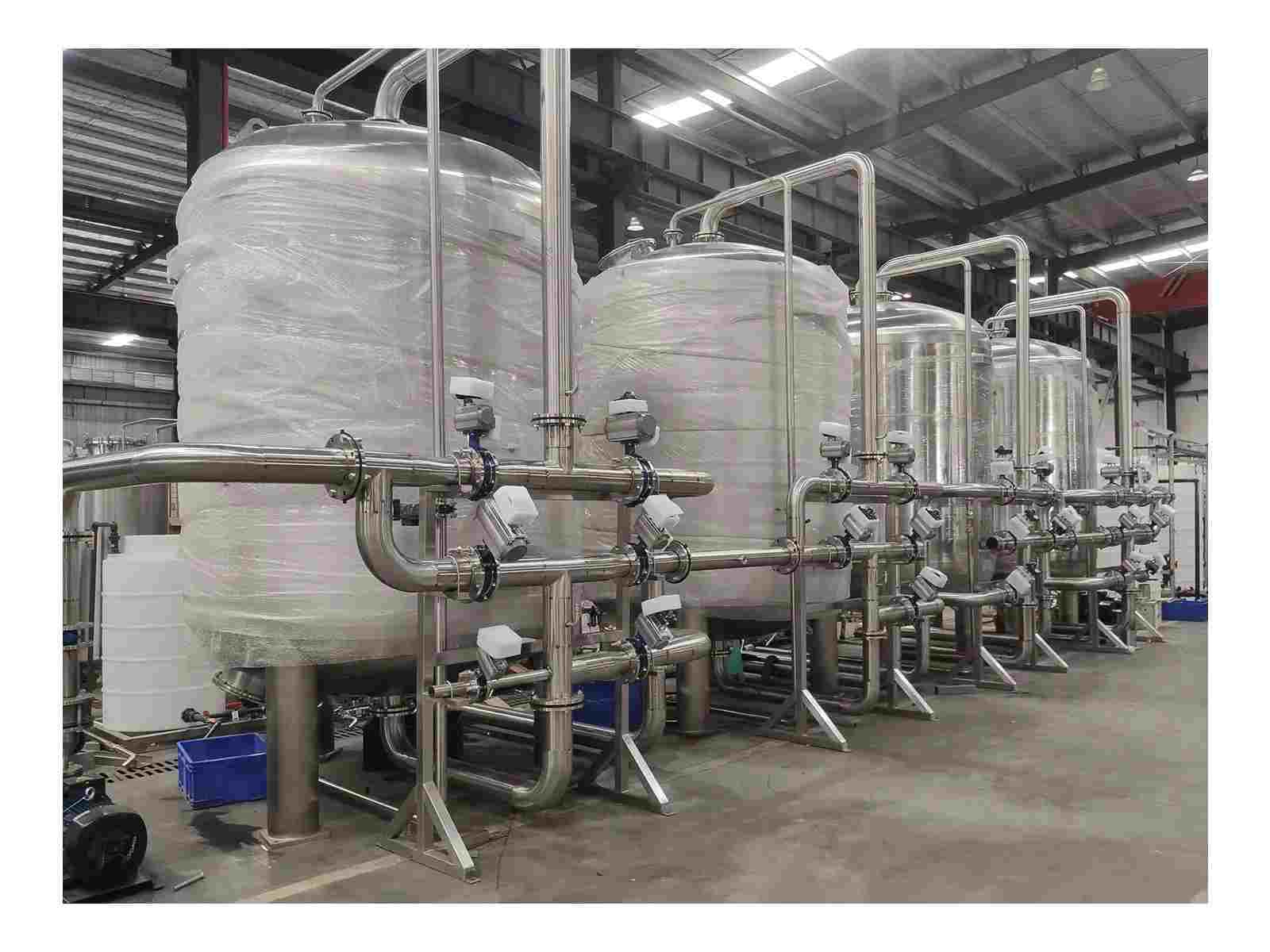

To convert tap water from the tap to 18.2 MΩ.cm pure water the system has to employ the use of a “train” of purification technologies. Each stage targets a particular type of contaminants.

Stage 1: Pre-treatment

The first stage safeguards the RO membrane, which is the heart of the system. It generally includes deep filters(to get rid of silt as well as sand) as well as activated carbon (to get rid of the chloramines and chlorine). It is essential to remove chlorine since it has the ability to be chemically “burn” and degrade sensitive membranes.

Stage 2: Reverse Osmosis (RO)

Reverse Osmosis can be the best and economical method to eliminate the majority of impurities. Through the application of pressure to the water, it is forced into a semi-permeable barrier eliminating 95-99% of inorganic bacteria, ions as well as organic material.

Stage 3: Deionization (DI) and EDI

In the wake of RO, it becomes “pure” but not “ultrapure.” Ion exchange resins, also known as Electrodeionization (EDI) modules are used to exchange the remaining hydrogen and hydroxylions for the dissolved minerals. EDI is becoming more popular due to the fact that it makes use of an electric current to replenish resins, removing the requirement of chemical regenerants.

Stage 4: Polishing (The Final Step)

To get to that 18.2 MΩ.cm threshold, the water goes through an “polishing” loop:

- UV photo-oxidation (185/254nm) breaks the Organic trace molecules (TOC).

- Ultrafiltration (UF) is an essential component of life sciences. It removes Pyrogens (endotoxins) along with nucleases.

- Terminal Filter 0.22mm membrane that is placed at its point of usage, to ensure that there are no bacteria or particles that enter the vessel for collection.

Ultrapure Water Systems vs. Bottled Water: Why Make Your Own?

For small laboratories, buying “HPLC-grade” water in bottles might look like an easy option but an on-site Ultrapure Water system is the best choice for three reasons:

- Instant Contamination: The water is purest and a very strong solvent. Opening the bottle will cause it to absorb CO₂ from the air immediately thus lowering its resistivity. It will also extract plastic particles from the bottle’s interior walls.

- Continuous Monitoring: The latest systems give instantaneous readings of conductivity and TOC. In the case of bottled water, you have to rely on a batch certificate that could be as much as two months old.

- Cost Efficiency: Although the initial investment is quite high, the cost per liter of water produced in-house is much lower than that of buying, transporting, and disposing of plastic bottles.

How to Choose the Right Ultrapure Water System?

Choosing a system requires balancing your feed water quality with your application needs.

Configuration Decision Matrix

| If your lab does… | You need… | Key Component |

| Basic Chemistry / Titration | Type II Water | DI Resin Cartridges |

| Analytical (HPLC, GC, MS) | Type I (Low TOC) | Dual-wavelength UV Lamp |

| Molecular Biology / IVF | Type I (Apyrogenic) | Ultrafiltration (UF) Module |

| Heavy Daily Usage (>50L) | High-flow System | Large RO Storage Tank |

In addition, think about your feedwater. In case deionized water is already being provided by your building, you will only require a “polishing” system. However, if you are utilizing tap water, you will need an “integrated” system that will include the processes of RO and pre-treatment.

Maintenance to Sustain 18.2 MΩ.cm Quality Standards

The effectiveness of a system depends on its maintenance schedule. Filters, if neglected, can cause “breakthrough” wherein the contaminants pass through the resin and spoil your samples.

- Pre-treatment: It is recommended to change the RO membrane every 3-6 months to avoid fouling.

- Purification Packs: It is advisable to replace the packs when the resistivity alarm goes off (normally at 15 MΩ.cm) or once a year.

- Sanitization: The internal plumbing of the apparatus should be treated with chemical sanitizers every year in order to stop the “biofilm,” a thick and very inconvenient layer of bacteria, from forming and completely taking over the system since it is hard to get rid of once it is there.

The process of choosing the appropriate ultrapure water system for the laboratory is a very important investment in the reliability of your research. know the multi-stage purification process—from reverse osmosis to electrodeionization and ultraviolet treatment—and you will be sure that your application-specific requirements will be accurately met. It doesn’t matter if you are performing trace element analysis or delicate genomic research; a steady supply of water with a resistivity of 18.2 MΩ.cm is an absolute requirement.

Get to know the cutting-edge solutions from Molewater to design a water system that not only enhances productivity but also cuts down on long-term operating expenses and the highest purity that your scientific breakthroughs can have.