Water is often the first resource required in testing and research activities in the laboratory. The purity of the water will have a major effect on all the actions involved in testing and research; sample preparation, operation of the instruments, and result analysis. Clear water may have impurities that are less obvious such as trace ions, and microorganisms , as well as organic contaminants. These may result in experimental errors or damage high-cost instruments.

The required purity of water will change pending the scenario in which it will be used (for example, in chemical analysis, biological culture, drug R&D, and in the testing of materials). The question of how to select the proper pure water with all the varying factors to be considered in the water types (Type I ultrapure, Type II purified, and Type III reverse-osmosis treated) has become a major issue to a lot of researchers and laboratory administrators.

Importance of Laboratory Quality Water

Laboratory quality water is essential for providing a consistent and reliable benchmark with a focus on two key objectives – maintaining the precision of the results and safeguarding the high-value apparatus. Focusing on only one can significantly derail the progress of experiments.

1. Effect on the Precision of the Results of the Experiment

In every scientific study and analysis, attaining precise results is of utmost importance and one is preparation face some low quality water. Even the slightest impureness in the water, whether it be in the form of heavy metal ions, microorganisms, or some(fine) dissolved gases, will cause problems in the experiments in multiple ways. In the analysis of elements, heavy metal ions can react or be detected with the sample, causing results to be erroneous. In biological experiments, microorganisms cause the cell cultures to be contaminated, compete for nutrients, produce a toxin, or degrade the sample by DNA/RNA, causing problems in the sequencing of genes or in the PCR. Even in a simple experiment of titration, the dissolved gases in the water will cause the end point of the experiment to be skew. Standard records indicate the low quality of water is the cause of an increase in the error of the experiments by over 30% and in experiments with high precision the results are rendered useless. Therefore, to maintain accuracy and reproducibility, it is essential to select a water of appropriate purity.

2. Protective Effect on Experimental Equipment

The modern laboratories utilize expensive, high-precision equipment that has strict requirements for the quality of water, because of the damage unfit water can cause being irreversible. Water damage also raises the price of service and maintenance. Blocks of particles clog chromatographic columns, and erosion of ion contaminated filler replacement can cost tens of thousands. Nebulizers and torch tubes in ICP-MS/atomic absorption spectrometers are also sensitive to blockage and can cause loss of operational sensitivity for which downtime is needed. High hardness water is also problematic as it scales over time in autoclaves and distillers. This is inefficient, is a high energy user, and has associated safety/risk corrosion of safety equipment. The water that causes the erosion and blockage is a protective water which saves the parts from needing replacement more often, and erosion causing damage. This saves on long term costs, as it enables unbroken runs of experiments.

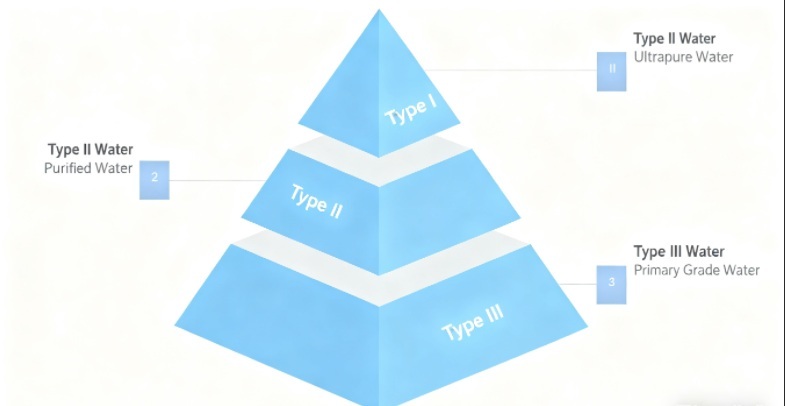

Different Types of Laboratory Pure Water

In laboratories, there are three different kinds of water depending on purity level and how they were processed that are labelled and categorised as: Type I (ultra-pure water), Type II, and Type III (RO water). Each of these has different standards of purification, varying costs, and different levels of applicability which calls for a certain selection based on what the experiment needs.

Type I Water (Ultrapure Water)

It is the highest-purity lab water, made via multi-stage advanced processes to eliminate almost all impurities. Key indicators are rigorous: resistivity hits 18.2 MΩ・cm at 25℃, TOC below 10 ppb (even under 5 ppb for high standards), microbes <1 CFU/mL, and particles (>0.2μm) ≤1 per mL. It is applied in high-precision scenarios like ICP-MS trace element analysis, DNA/RNA extraction and PCR amplification in molecular biology, mobile phase preparation for LC-MS, semiconductor chip cleaning, and high-accuracy standard solution configuration.

Type II Water

As the most widely used “basic water” in labs, its purity falls between Type I and III, with a simplified and cost-effective preparation process. Its resistivity ranges from 1 – 18.2 MΩ・cm (usually ≥10 MΩ・cm at 25℃), TOC <50 ppb, microbes <10 CFU/mL, and particles (>0.2μm) ≤10 per mL. It suits most routine experiments, including acid – base titration, sample dissolution and dilution, UV – Vis spectrometer sample preparation, non – sterile bacterial culture medium making, and reagent preparation for COD/BOD water quality testing.

Type III Water (RO Water)

It is the lowest – purity lab water, mainly produced by reverse osmosis at low cost. Its resistivity is 0.05 – 1 MΩ・cm at 25℃, TOC <200 ppb, and microbes generally <100 CFU/mL, with only loose limits. It is used for auxiliary tasks: preliminary cleaning of beakers and test tubes, cooling water for atomic absorption spectrometers to reduce scaling, wetting water for grinding soil samples, middle – high school teaching experiments, and pretreatment for high – purity water preparation to ease subsequent purification pressure.

How is Laboratory Water Purity Assessed?

Measuring the purity of laboratory water involves having exact measurable values for determining the laboratory water quality class for safe water quality use for the laboratory work/experiments.

Major Purity Criteria

Measurable Quality of Water are the primary indicators for determining water quality for measuring water quality impurities for laboratory work. They mainly include conductivity (or resistivity metric) for measuring ionic impurities) total organic carbon, particulate, and microbial.

Electrical Conductivity or Resistivity

Measurement (and its inverse) of ionic impurities (resistivity = 1/conductivity) and higher ion concentration < conductivity, which are measured in μS/cm and MΩ・cm (25 degree celsius). Laboratory water standards/conductivity indicators are: Type I (18.2 MΩ・cm, ~0.055 μS/cm) water, Type II (≥10 MΩ・cm, ≤0.1 μS/cm) water and Type III (≥0.05 MΩ・cm, ≤20 μS/cm) water. A temp with 25 degree Celsius must recorded.

Total Organic Carbon (TOC)

Measures total organic pollutants (in ppb or ppm) that permeate and/ or alter chromatographic processes, or stimulate microbial growth and its limits are Type I water <10 ppb (or <5 ppb for higher standards); Type II water <50 ppb and Type III water <200 ppb). The total organic carbon is measured using e.g. combustion oxidation or UV oxidation-non-dispersive infrared absorption, which must be of ppb measurement quality.

Suspended Solids >0.2μm in size, expressed in particles/mL, which vary by instrument model. Critical limit(s): Type I ≤1, Type II ≤10, Type III ≤100 – if not listed, not obligatory. Determination by Instantaneous Laser Particle Counters (I.L.P.C) of high precision.

Microbiological Contamination

Due to the presence of bacteria, fungi, etc., expressed as colony-forming units (CFU/mL). Type I: ≤1, Type II: ≤10, Type III: ≤100. Plate counting, membrane, and mixed filtration methods (efficient membrane) with online counting have gained ground.

How to Choose the Right Pure Water System?

To pick the right type of water purification system, each lab must first determine the experimental needs, then the type of high purity water they will need by considering the type of experiment, how precise the experiment must be, and how the water will be used.

Generally, if the lab performs high precision experiments like ICP-MS, HPLC-MS, gene sequencing, cell culture, they will need systems that produce Type I ultrapure water. For tasks that require less water purity, like regular chemical analyses, pre-treatment of samples, or cleaning glassware, they can use a Type II water system which is more economical. For really simple tasks like cooling off equipment, pre-cleaning, or diluting a solution, a Type III reverse osmosis water system is the best option from an economical standpoint. h real-time monitoring/alarm–stopping water supply immediately if standards are exceeded to protect patients.

Water consumption also needs to be considered as they will all require a different volume of water per day. For example, a benchtop system extracting 5–20 L a day will be best for small labs, a floor-standing system extracting 20–100 L a day will suit medium labs, and an industrial system that can extract over 100 L a day will be best for large continuous use labs. If a lab needs water 24/7, systems that have a stable uninterrupted output for a long time, backup systems, or systems that can fail over without disrupting the experiment need to be used.

Bottom Line

With the rapid iteration of scientific research technology, laboratories have higher requirements for water purity, stability and supply efficiency, and pure water preparation technology continues to make breakthroughs towards high efficiency, stability and intelligence. Molewater Laboratory Water System is an excellent choice in the scientific research field with advanced technology and flexible adaptability.

Covering multiple series such as Molgene and Molatom, it can accurately produce Type I ultrapure water to Type III reverse osmosis water, meeting the needs of molecular biology, analytical chemistry and other scenarios, and adapting to various precision experiments such as PCR, HPLC and gene sequencing. Don’t hesitate, choose your laboratory water system at Molewater!