With the acceleration of urbanization and the continuous advancement of industrial development, the amount of sewage discharged is constantly increasing, which puts forward higher requirements for water environmental protection. To achieve sustainable utilization of water resources and long-term environmental security, modern sewage treatment technologies must take into account both treatment efficiency and economy. Among various sewage treatment technologies, the activated sludge treatment (activated sludge wastewater treatment) remains the core technology of modern sewage treatment plants due to its stable treatment effect, mature operation and strong scalability.

As a professional provider of wastewater treatment solutions, Molewater has rich experience in the design and operation of activated sludge systems. This article will focus on the activated sludge process and comprehensively analyze its role in wastewater treatment, providing a reference for professionals engaged in wastewater treatment or enterprise managers.

What is Activated Sludge?

Activated sludge is a complex mixture composed of microbial communities, colloidal particles and undegraded organic matter, and it has high biological activity. During the wastewater treatment process, activated sludge can degrade organic pollutants in water through the metabolism of microorganisms, and at the same time participate in the removal of nutrients such as nitrogen and phosphorus. It is the core biological medium for wastewater purification.

Microorganisms play a leading role in activated sludge, decomposing complex organic matter into carbon dioxide, water and harmless by-products through aerobic or facultative metabolism. In addition, the types and quantities of microorganisms in activated sludge have a decisive impact on the treatment efficiency. Therefore, maintaining a stable microbial community is the key to the efficient operation of the activated sludge treatment.

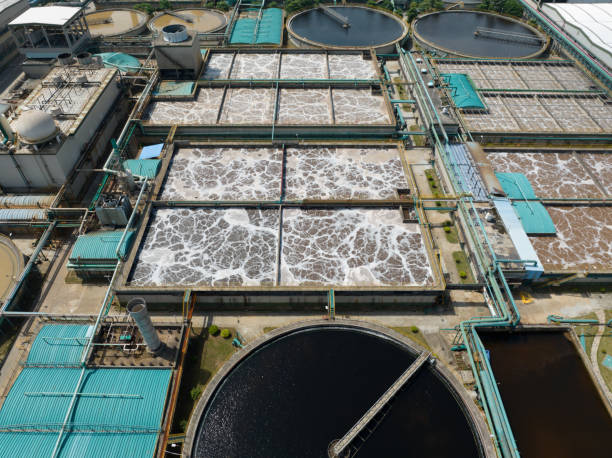

What Is An Activated Sludge Wastewater Treatment Plant?

The activated sludge wastewater treatment plant is a wastewater treatment system with the activated sludge treatment as its core technology. Its design concept is to convert pollutants into stable and harmless substances by controlling the growth environment of microorganisms. Its main components include:

Aeration tank: It provides microorganisms with sufficient oxygen through air or oxygen, enabling them to efficiently decompose organic matter under aerobic conditions. Aeration methods can adopt surface aeration, deep water aeration or blower aeration. The most suitable method should be selected based on the water volume and water quality.

Secondary sedimentation tank: It separates activated sludge from purified water through gravity sedimentation, ensuring clear effluent and maintaining stable system operation.

Sludge return system: Part of the settled sludge is returned to the aeration tank to maintain the concentration and activity of microorganisms.

Excess sludge discharge system: Regularly discharge the excess sludge to prevent system overload and further carry out sludge dewatering treatment.

The entire sewage treatment plant forms a circulation system through these links, achieving continuous and efficient purification of wastewater while ensuring that the effluent quality meets the discharge standards.

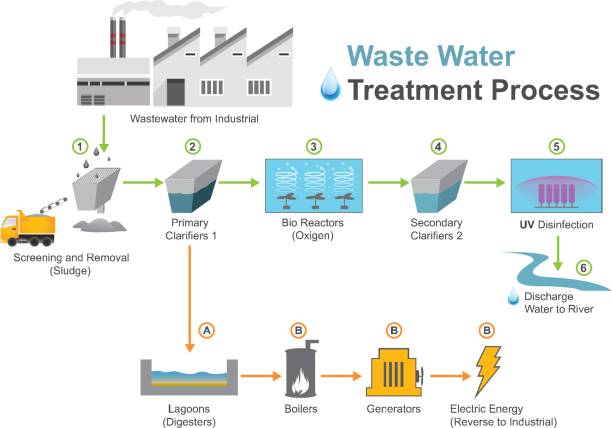

Working Principle of the Activated Sludge Treatment

The core process of the activated sludge method consists of three steps: aeration, sedimentation and sludge return, forming a biochemical circulation system

1. Aeration stage

After the wastewater enters the aeration tank, dissolved oxygen is provided by mechanical or blower equipment, allowing microorganisms to reproduce and metabolize in an aerobic environment. Microorganisms use organic matter as energy, breaking it down into simple compounds while growing to produce more biomass.

2. Sedimentation stage

After the wastewater flows into the secondary sedimentation tank, the activated sludge particles are separated by gravity sedimentation. Part of the settled sludge is recycled to the aeration tank to maintain the stability of the microbial community, while the rest is discharged from the system as excess sludge.

3. Recycling and Emission

This cycle mechanism enables sewage to be continuously purified under the action of microorganisms, while maintaining system balance and preventing excessive accumulation of sludge or insufficient microorganisms.

By scientifically controlling the aeration time, sludge return ratio and retention time, the activated sludge treatment can efficiently remove organic pollutants and some nutrients from wastewater, while reducing operating costs and energy consumption.

How Is Activated Sludge Used To Clean Sewage?

In wastewater treatment, activated sludge mainly relies on the biochemical action of microorganisms to remove pollutants. The mechanisms include:

- Adsorption effect: Activated sludge particles have a large specific surface area, which can adsorb suspended particles and some dissolved organic matter in water, thereby improving the treatment efficiency.

- Biodegradation: Microorganisms break down complex organic matter into carbon dioxide, water and harmless by-products through enzymatic reactions, while converting some pollutants into the cells’ own biomass.

- Nitrogen and phosphorus removal: Specific microorganisms can convert nitrogen into nitrogen gas through the nitrification and denitrification process for discharge, achieving nitrogen removal. Some microorganisms can absorb phosphorus and fix it within their cells, achieving a biological dephosphorization effect.

Through the above mechanism, activated sludge can remove various pollutants and ensure that the effluent quality of wastewater meets environmental discharge standards.

Main Advantages of the Activated Sludge Treatment

The activated sludge treatment has the following significant advantages:

- Stable treatment effect: Adaptable to different water qualities and wastewater loads, with excellent effluent quality.

- Strong adaptability: It can handle various organic pollutants and has a certain ability to remove nutrients such as nitrogen and phosphorus.

- High scalability: Suitable for medium and large-scale sewage treatment plants, and the system scale can be adjusted according to actual needs.

- Mature and reliable: The process is mature, the operation experience is rich, the equipment maintenance is relatively easy, and the operating cost is controllable.

- Good compatibility: It can be combined with membrane technology, chemical precipitation or biological nitrogen and phosphorus removal processes to meet higher standards of wastewater treatment requirements.

These advantages make the activated sludge treatment applicable to a variety of modern wastewater treatment fields:

- Municipal sewage treatment: Suitable for large-scale and continuous operation, it is used to treat urban domestic sewage and ensure stable effluent quality.

- Industrial wastewater treatment: It has a remarkable effect on the treatment of high-concentration organic wastewater from industries such as food, pharmaceuticals, chemicals, and papermaking.

- Combined process application: It can be combined with improved processes such as A/O, A2/O, SBR, and MBR to enhance the nitrogen and phosphorus removal capacity or meet the wastewater treatment requirements of higher loads.

What Factors Influence The Efficiency Of The Activated Sludge Process?

System efficiency is influenced by multiple factors, mainly including:

- Dissolved oxygen (DO) : Microorganisms require sufficient oxygen for aerobic metabolism. Insufficient DO can lead to a decline in degradation capacity.

- Sludge age (SRT) and sludge concentration: They affect the stability of microbial communities and metabolic efficiency.

- Food-to-microorganism ratio (F/M) : The ratio of wastewater load to the number of microorganisms. If it is too high, it may lead to sludge bulking; if it is too low, the activity of microorganisms will decline.

- Temperature and pH: They directly affect the activity of microorganisms, and different microorganisms have different adaptability to environmental conditions.

- Toxic substances: Heavy metals, organic solvents or surfactants may inhibit the growth of microorganisms.

- Sludge settling property (SVI) : Poor settling performance can lead to sludge overflow from the secondary sedimentation tank, affecting the effluent quality.

By real-time monitoring and reasonable regulation of operating parameters, the efficient and stable operation of the activated sludge system can be maintained.

What Are Common Problems Encountered In Activated Sludge Systems And How Can They Be Addressed?

In actual operation, the activated sludge system may encounter the following problems and corresponding strategies:

Sludge bulking: Excessive growth of filamentous bacteria leads to poor sedimentation, which can be addressed by adjusting the nutrient ratio, reducing the reflux ratio or adding flocculants.

Sludge aging: The aging of the microbial community leads to a decline in treatment capacity, which can be improved by adjusting the sludge age or appropriately supplementing activated sludge.

Foam problem: It is mostly related to surfactants or filamentous bacteria and needs to be solved by mechanical defoaming or controlling aeration conditions.

The effluent does not meet the standards: It may be due to insufficient dissolved oxygen, excessive load or unreasonable sludge return. It is necessary to strengthen monitoring and optimize the aeration volume and return ratio.

A scientific monitoring system, standardized operation and regular maintenance are the keys to ensuring the efficient operation of the activated sludge treatment.

Final Words

The activated sludge treatment, with its efficient, stable and mature treatment technology, remains the core technology of modern sewage treatment plants. By scientifically managing microbial communities, optimizing aeration and sludge return, and monitoring key parameters, sewage treatment plants can achieve high-quality wastewater purification.

Molewater has rich experience in the design, operation and optimization of activated sludge systems, providing reliable and sustainable solutions for municipal and industrial wastewater treatment. With the development of intelligent monitoring and optimized control technologies, the application of the activated sludge process will become more efficient and energy-saving, providing a solid guarantee for water environmental protection and the sustainable development of enterprises.

Choosing the activated sludge process means choosing a stable, efficient and sustainable future for wastewater treatment.