If you’re in charge of making major decisions as the manager of hospitals, clinics, or research centers, we know it isn’t easy picking the right Medical Wastewater Treatment Solution. Medical wastewater is comprised of complex pollutants like bacteria, viruses, chemicals, and heavy metals. If not treated properly, it leads to severe penalties by the environmental authorities and poses risks to the health of the general public. Adding to the frustration is the great variety of such solutions available on the market, as you are sure to focus on the lowest cost, lowest quality non-compliant solutions, and the unreliable suppliers with poor service. Based on your real and actual needs, we will help you chart your course to avoid unseen pitfalls, and obtain a reputable Medical Waste Water Treatment System.

Clarify Your Medical Wastewater Treatment Needs

The first step in selection is understanding your situation. No advanced solution works if disconnected from your actual needs—only by clarifying your scenario, compliance requirements, and pollution characteristics can you find the right treatment system.

Precise Scenario Positioning

Medical institutions differ greatly in wastewater output and needs. Large hospitals generate thousands of tons daily from clinics, wards, operating rooms, and labs. Small clinics/community hospitals produce under tens of tons per day with simpler components. Research labs’ wastewater has high-concentration chemicals/heavy metals (stricter treatment needed), while aesthetic facilities focus on cosmetic residues and disinfection wastewater.

Calculate daily treatment capacity (peak and average volumes) accurately. This determines equipment scale, avoiding cost waste from “overcapacity” or non-compliance due to “insufficient capacity”.

Understand Pollution Characteristics

The range of the pollutants present will determine what treatment route is necessary. Identify what the primary types will be. These will be pathogenic microorganisms: bacteria, viruses and eggs of parasites which will be from wards and clinics, or the chemicals and heavy metals from laboratories, and from operating theatres the high concentration COD/disinfectant residues.

Get professional sampling done to determine the concentration data which will include COD, BOD₅, ammonia nitrogen, total phosphorus, heavy metals, and so on. This information is crucial in determining what the most efficient treatment option is.

Is the Treatment Technology Suitable?

The technology route is the core of a medical wastewater treatment solution—choosing the right technology fundamentally guarantees effectiveness. Different pollution characteristics demand specific processes; blind pursuit of popular technologies often leads to losses.

Technology Route Matching

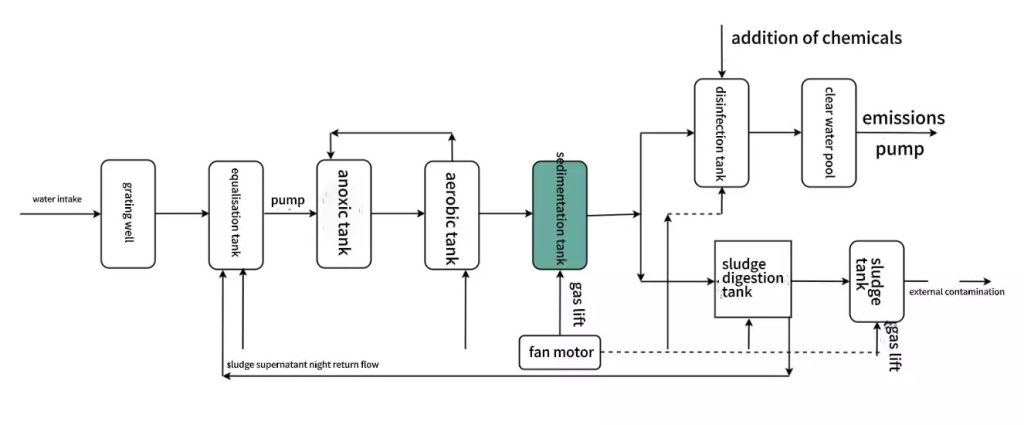

The mainstream route today is “pretreatment + biochemical treatment + advanced disinfection + sludge disposal”. The precision of grating, quartz sand filtration, and the activated carbon adsorption processes help to remove the suspended particles and organics to help lessen the incoming workload a little during pretreatment. During the crucial biochemical step, the AO/MBR processes and those like it get rid of COD, BOD₅, NH₄+, and TP through the actions of microorganisms, which are also quite common in the other steps. Ozone/UV and other advanced disinfection processes kill any remaining pathogens, which helps to make the effluent safe. (physical pressure avoids secondary pollution); 70%-80% water recovery rate (far beyond traditional 30%-50%, saving resources). Modern systems also employ membranes with low pressure (which reduce energy consumption) as well as Membranes that prevent pollution (which are more durable) as well as staged filtering (which performs better) to ensure the highest quality outcomes.

If the wastewater is pathogen rich, then the disinfection is usually the most important step to consider. In cases of wastewater with higher levels of chemicals/easy to oxidize materials and heavy metals, the addition of coagulation sedimentation, then disinfection, is suggested. The addition of anaerobic digestion is often required for higher concentration organic wastewater, and in laboratory situations, for additional pretreatment steps.Verify the route specifically addresses your pollution issues.

Technology Maturity

Vital for compliance and public safety, maturity requires practical medical industry applications—especially cases matching your institution’s scale and pollution type. Request detailed supplier case reports with treatment capacity, influent/effluent quality, compliance status, and operation duration.

Mature technologies stably remove target pollutants without post-initial fluctuations. Check industry reputation and long-term verification to avoid unproven new technologies, reducing selection risks.

Adaptable Intelligence Level

Medical institutions focus on healthcare, so wastewater operations shouldn’t drain resources. High-quality systems feature full automation—covering inflow, reaction, sedimentation, and disinfection—with sensors real-time monitoring water quality/volume and auto-adjusting operations.

Intelligent systems cut manual work and human-error failures, while data analysis identifies potential issues. For small institutions with limited staff, they significantly reduce operational pressure and ensure stable performance.

Medical Wastewater Treatment Equipment and System Reliability

Once the technology route is confirmed, equipment and system reliability directly determine the stability of treatment effects and service life. Medical wastewater treatment requires long-term continuous operation—substandard equipment leads to frequent failures, disrupting operations and risking environmental non-compliance.

Core Component Quality Compliance

Key components (filter materials, disinfection equipment, pumps, sensors) directly impact efficiency and stability. Filter media like quartz sand and activated carbon must meet industry standards with reliable adsorption/filtration performance and guaranteed service life. Disinfection equipment (ozone generators, UV lamps) needs sufficient sterilization power, stable operation, and durability. Pumps, valves, and other general equipment should be reputable brand products with good sealing, corrosion resistance, and low failure rates.

Robust System Stability

24/7 continuous operation is essential, especially for large hospitals—system shutdowns leave untreated wastewater un dischargeable, potentially disrupting medical services. Prioritize systems with comprehensive protection designs (overload protection, voltage fluctuation protection, fault early warning) that auto-shut down or alert in abnormalities to prevent damage. Rational structural and pipeline design reduces clogging and leaks. Inquire about the system’s mean time between failures and historical failure records from suppliers.

Comprehensive Sludge Disposal Capacity

Medical wastewater treatment generates sludge containing pathogenic microorganisms and pollutants—classified as hazardous waste. Improper disposal causes secondary pollution and environmental penalties. Reliable solutions must include complete sludge disposal modules.

High-quality systems should be equipped with sludge thickening, dewatering, and harmless treatment equipment to reduce moisture content to compliant levels for safe transportation. Suppliers should provide technical guidance and compliance advice for full-cycle environmentally friendly sludge disposal. Avoid neglecting this link when selecting solutions to prevent operational risks.

Practical Steps: 3 Ways to Quickly Lock Reliable Solutions

- Preliminary Research: Clarify own needs + collect solutions from 3-5 suppliers;

- On-Site Inspection: Visit the supplier’s past successful cases in the medical industry to verify equipment operation effect;

- Details: Specify technical parameters, compliance commitments, service terms, and warranty period.

In the End

Medical wastewater treatment is not only a requirement for environmental compliance but also a reflection of medical institutions’ social responsibility. Choosing a reliable treatment solution not only avoids environmental risks but also reduces long-term operational costs, providing guarantee for the smooth conduct of medical activities.

If you are still unclear about your own needs or require professional technical support, you can consult Molewater’s professional team. With years of experience in the medical wastewater treatment industry, Molewater is capable of providing customized solutions for various types of medical institutions.