Hospital wastewater treatment is a lot more difficult than that of the household since it contains various kinds of harmful microbes (bacteria, viruses) and toxic chemicals such as antibiotics, cytotoxic drugs, heavy metals, and a high concentration of organics. If not done in the right way, treatment of such wastewater will become not only a sources of pollution of water bodies but also the cause of the rapid spread of disease and the increase of drug resistance. The stricter the rules like those in China and the WHO criteria for the maximum concentration of antibiotics in wastewater or heavy metals in biological treatment effluent were, the more the hospitals worldwide would be stressed under their system It also has a very devastating effect in every direction.

This article explores core challenges in hospital wastewater treatment and actionable solutions, helping institutions achieve safe, efficient, and compliant water management.

Challenges in Wastewater Treatment in Hospitals

Complex and Fluctuating Water Quality

The problem with hospital wastewater, as it is to be known, is the wide range of attributes resulting from the considerable changes in it. First of all, it contains a wide range of pathogens and microorganisms (e.g. disease-causing bacteria, parasites, fungi, viruses) that are more than 5-10 times the standard concentration. Secondly, it has all kinds of chemicals including the ones not removed by the biological treatment (e.g. drugs, heavy metals). Thirdly, the physical impurities consist of not only blood from different wards but also tissues, parts, etc. Forth, the volume and strength of pollution in wastewater increase by 50-80% in peak hours or during disease outbreaks and this results in water treatment plant shutdowns. The case is so severe that conventional processes can hardly cope with the highly variable wastewater and eventually they just perform poor in pollutant removal.

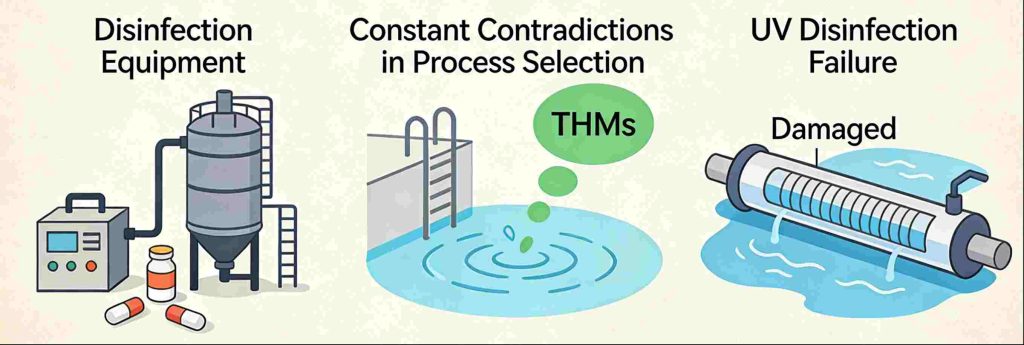

Improper Selection of Processes and Safety Hazards

A number of facilities have the problem of improper matching of technologies: infectious disease controlling hospitals that focus only on the use of equipment and disinfection do not think of the drug residues, whereas the hospitals using chlorine-based disinfection rate which exceeds 10% cause production of dangerous by-products like chloroform. The lack of proper pretreatment results in the occurrence of high levels of suspended solids (SS) which in turn leads to the almost total loss of the UV disinfection effectiveness. Moreover, the non-treatment of medical sludge containing pathogens results in a lot of space coverage, odors are produced and pathogens are, therefore, released, in this way causing secondary pollution and not only violating the pollution law.

Low Automation and Operational Inefficiencies

The majority of the treatment systems are based on manual operation round the clock. Simultaneous adjustment of chemical dosing rates by experience is a normal thing. However, variations are subsequently witnessed—the residual chlorine, for example, could vary by up to 0.5 mg/L. It’s very easy to lose the records if only manual data recording is done; compliance tracing is then hampered. Shortages of professional staff directly lead to delayed responses during emergencies caused by equipment faults or sudden quality lapses which in turn raise non-compliance risks.

Effective Wastewater Treatment Solution in Hospital

Customized Process Combinations

Core Process Configuration (Taking Molewater’s Solution as an Example)

| Process Stage | Key Technologies | Functions | Performance Indicators |

| Classified Pretreatment | Automatic grille + regulating tank + oil separator | Intercept large particles, balance water quality/volume, separate oil | Reduces SS by ≥60%; stabilizes inflow parameters |

| Efficient Biochemical Treatment | MBR membrane bioreactor + hydrolysis acidification | Degrade organics, intercept pathogens, improve biodegradability of refractory pollutants | COD removal ≥90%; ammonia nitrogen removal ≥85% |

| Advanced Treatment & Double Disinfection | Activated carbon adsorption + ozone/UV | Remove drug residues/heavy metals; kill pathogens without by-products | Pathogen removal ≥99.9%; refractory pollutant removal ≥60% |

| Harmless Sludge Disposal | Concentration + screw press dehydration + disinfection | Reduce sludge volume and eliminate pathogens | Sludge moisture content ≤80%; meets medical waste standards |

Smart Automatic Control Systems

Molewater’s fully customized PLC control cabinets allow complete process automation: pH, COD, and residual chlorine real-time monitoring (data delay ≤3 seconds) with automatic parameter adjustment (error ≤0.1%). Data storage up to 5 years via cloud allows for easy compliance verification. Emergency routines are automatically set to react by increasing disinfection or switching to a standby facility during epidemics or chemical spills, shortening the time for fault repair by 70%.

Cost and Energy Efficiency Optimization

- Energy Saving: Frequency conversion fans/pumps and AI algorithms contribute to energy saving of 20%-25%.

- Resource Reuse: The water treated is used for landscaping or flushing – that way more than 30,000 tons are saved yearly per tertiary hospital.

- Consumable Reduction: The use of Precision Dosing Systems decreases the chemical usage by 15%-18%, and practically anti-pollution MBR membranes also elongate their service life to 3-5 years, which furthermore reduces costs .

Why Choose Molewater Hospital Wastewater Treatment?

Molewater stands out as an indispensable partner to healthcare facilities due to its dedication to “100 years of doing one thing well”. As an independent large-scale production workshop, we ensure full process quality monitoring from manufacturing through delivery. Strict adherence to standard production practices and an industry-leading quality assurance system guarantees every piece of equipment meets stringent industry standards, while their professional installation team and systematic management ensure safe construction on-site. Molewater places particular importance on transportation safety, with its special packaging designed to minimize damage risks during shipping. Serving thousands of global enterprises since 1997, Molewater provides customized end-to-end solutions-from process design through post installation support – that integrate reliability, efficiency and sustainability for long-term operational cost savings in healthcare institutions.

The Bottom Line

Dealing with wastewater in hospital is a very important merging of several big public health, environmental and regulatory issues, which could be solved with specific and advanced solutions. Hospital could become a brake in the sustainability target and still be outside of the environmentally responsible spectra if it does not turn the highly complex burden into a sustainable project of good practice. When the regulations get tougher and the technologies get better, the best way to ensure not only compliance and cost savings but also the protection communities and the ecosystems is through the reliable systems such as Molewater’s. It is not just about following the rules for health care organizations; but also producing world health and sustainability through proper holistic care and proactive wastewater management.