Reverse osmosis (RO) systems have risen to become the main technology used for water treatment in homes, industries, and even in ocean water desalination, with RO membranes as the major determining factor that removes all impurities and guarantees water quality. Nevertheless, RO membrane problems are bound to occur throughout the process of continuous operation, they will have a direct effect on the efficiency of water production, the quality of treated water, and even the overall costs of operation. Problems can range from smaller outputs of water to the cutting down of desalination rates and thus causing disruptions in the production timetable or even leading to failure in meeting the water quality standards.

This article comprehensively analyzes common RO membrane problems, provides targeted diagnostic methods and practical solutions, and offers prevention strategies to help operators extend membrane lifespan and maintain system stability.

Common RO Membrane Problems and Cause Diagnosis

Decreased Water Production

Decreased water production is ranked high among the problems that confront RO systems. The main sources of this problem are membrane fouling with suspended particles and deposition of organics, insufficient pressure of the feed water, lower water temperature and membrane dullness. To make a fast diagnosis, operating parameters (e.g., feed water pressure, temperature) should be compared with baseline data—typically reduced pressure or lower temperature leads to reduced output. Besides, look for visible tanks of deposits on the membrane surface which indicate fouling.

Reduced Desalination Rate

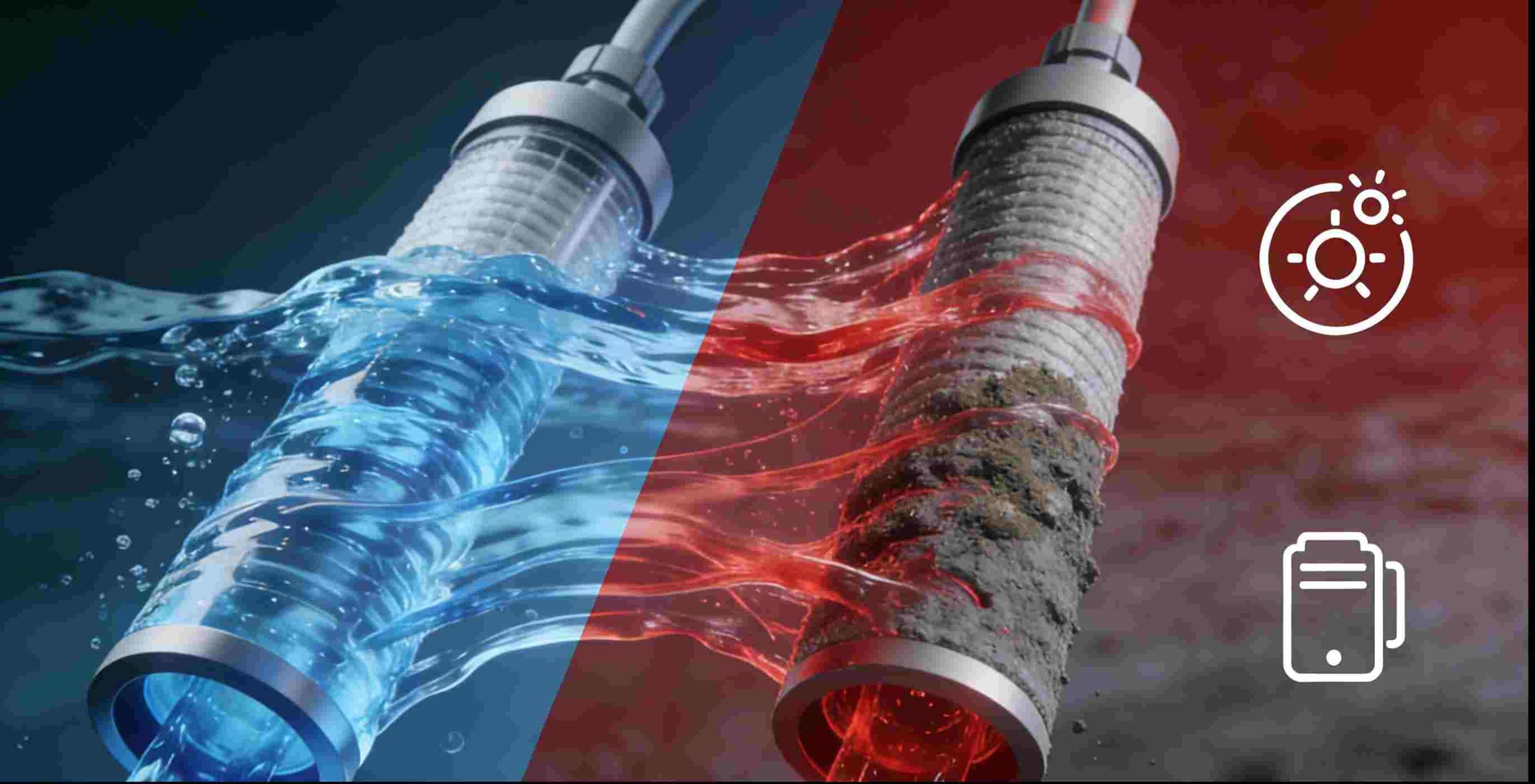

A desertion in the desalination rate signals that the membrane is not performing its function of removing salts effectively thus the product water is of poor quality. The main culprits are membrane fouling, wear and tear (with scratches or ruptures) and abrupt change in feed water quality like abnormal salinity or pH levels. Employ a TDS meter to check the product water—high TDS values are indicative of decreased desalination efficiency. A membrane integrity test should be carried out to detect damage due to wear and tear.

Increased Operating Pressure

High operating pressure is generally caused by membrane pore blockage, less than efficient discharge of concentrated water (which can be due to clogged pipes or malfunctioning valves), or very high feed water flow rates. It is advisable to monitor the pressure difference between the feed and permeate sides—if the difference shows an abnormal increase, that means there is blockage. Check the concentrated water pipeline and valves for unobstructed flow.

Microbial Contamination

Microbial contamination occurs when water sources have microorganisms or bacteria proliferate due to the lack of usage during the shutdown period of the equipment. Symptoms of this problem are offensive odors coming from the membrane surface and the results of positive bacterial tests in the product water. This problem is water quality and membrane life issue simultaneously.

System Water Leakage

Leakage from the system is primarily attributed to the deterioration of seals or their wear out over time and loosening of the connections. The first step is to visually inspect the interfaces of the pipes and the seals of the membrane housing for any water infiltration. A pressure test can be done to detect any leaks even if they are very small because these minor leaks can lead to water wastage and thus reduced efficiency of the system.

Targeted Solutions for RO Membrane Problems

Physical Cleaning for Loose Contaminants

Low-pressure flushing is considered to be an effective method of eliminating loose deposits. The procedure should be performed at 20-30% of normal pressure for 10-15 minutes. Permeate water or filtered raw water should be used for flushing to prevent recontamination of the system. Backwashing is suitable for mild fouling, where few impurities are trapped inside the membrane and the flow direction is reversed to free them—just ensure that backwash pressure does not exceed the membrane’s limit so as not to cause damage.

Chemical Cleaning for Stubborn Contamination

Acid cleaning (using citric acid or hydrochloric acid) addresses inorganic scale and the alkali cleaning (sodium hydroxide) takes care of the organic and microbial fouling. The operating specifications must be strictly followed: control the concentration of the chemical (for example, 1-2% citric acid), the temperature (25-35°C), and cleaning time (30-60 minutes) must be observed. In the case of very severe microbial contamination, cleaning with an oxidant should be done with proper safety gear to protect the operators.

Equipment Parameter Adjustment

Restoration of efficiency through operating parameters optimization: feed water pressure adjustment to the manufacturer standards, heating or cooling devices usage for water temperature maintenance at 25-35°C (the optimal range for RO membranes), and feed and concentrated water flow control within recommended limits to prevent membrane overloading.

Component Replacement for Irreversible Damage

Replacement of RO membrane elements when the performance cannot be restored through cleaning (e.g., water production stays 20% below baseline). Correct order of actions: system shutdown, water draining, old element removal, and new one installation with the right alignment. Early sealing and valve replacement of the ones that have lost their life, picking the models that suit the application for a good seal.

Prevention Strategies to Extend Membrane Lifespan

Preventive maintenance is always a better choice due to its lower cost. Seize the opportunity to do a pre-treatment by installing PP cotton filters (3-6 months scheduled replacement) and thus removing large particles and chlorine with the help of carbon filters (6-12 months scheduled replacement). For high turbidity or hardness raw water, use additional treatment like coagulation or softening.

Establish a regular maintenance plan: do low-pressure flushing daily and keep track of key parameters (water production, TDS, pressure). Chemical cleaning should be done every 3-6 months or when the pressure difference has increased by 15%. The feed water quality should be controlled (pH 2-11, low microbial count) and the proper preservation measures should be employed during the shutdowns—flush with a preservative solution for long-term downtime.

Solution Comparison for RO Membrane Problems in Different Scenarios

| Application Scenarios | Common Problems | Priority Solutions | Prevention Focus |

| Household RO Water Purifier | Decreased Water Production, Filter Blockage, Poor Taste | Regular Replacement of Prefilter, Low-Pressure Flushing, RO Membrane Replacement | Timely Replacement of Prefilter, Avoid Long-Term Shutdown |

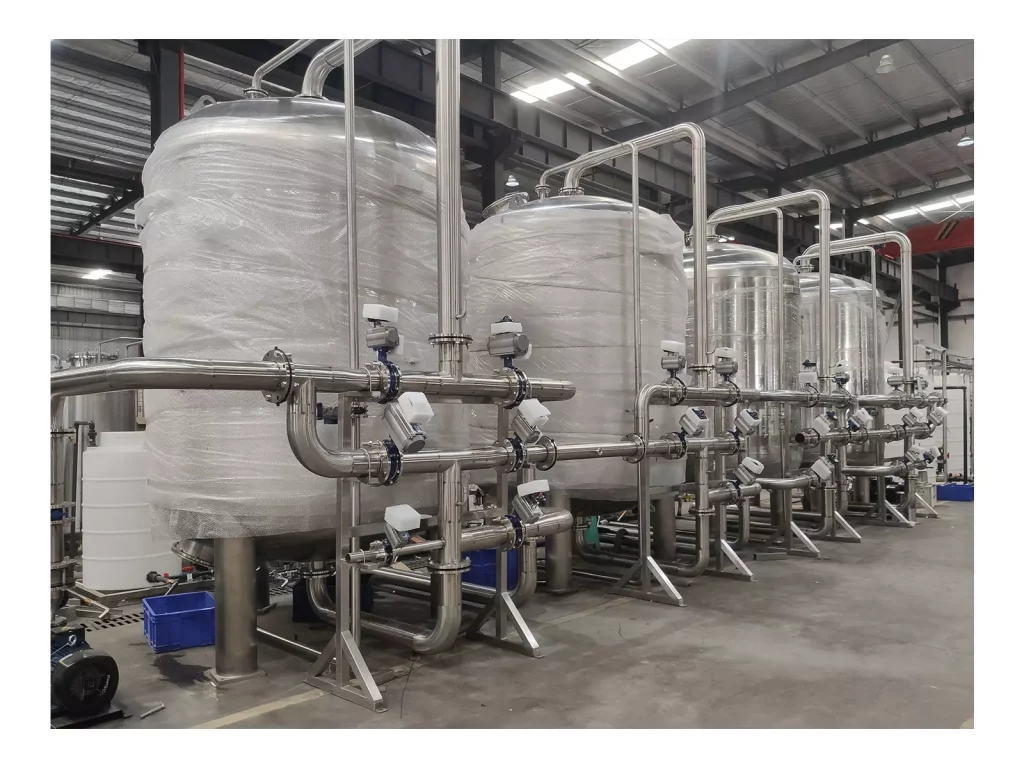

| Industrial Water Treatment RO System | Membrane Fouling, Reduced Desalination Rate, Increased Pressure | Optimize Pretreatment, Chemical Cleaning, Parameter Adjustment | Real-Time Water Quality Monitoring, Regular Chemical Cleaning, Standardized Operation Process |

| Seawater Desalination RO System | Scaling, Membrane Oxidation, High-Pressure Faults | Adding Antiscalants, Oxidant Cleaning, Pressure Control | Strict Pretreatment, Precise Chemical Dosing, Equipment Anticorrosion |

Conclusion

The proper treatment of RO membrane problems relies on the sequence of “diagnosis first, treatment second, prevention first.” The adoption of the right solutions along with proactive maintenance would not only cost less but also increase the efficiency and lifetime of the membrane. For the stable and trouble-free operation of your system, select the premium RO membrane housing of Molewater that is built for safeguarding membranes and steady operation, thus, effectively catering to your water treatment requirements.