Against the backdrop of worsening global water scarcity and tightening environmental regulations, efficient treatment and recycling of industrial wastewater have become key issues for enterprises’ sustainable development. As an advanced water treatment concept and technology system, Zero Liquid Discharge (ZLD), with the core goal of “no liquid wastewater discharged into the environment”, has gradually become an important choice for various industries to solve wastewater problems and achieve green production. Then, what exactly is ZLD? What key links does its treatment process include? And what technical types and practical application scenarios are there? This article will explain the core content of ZLD from multiple dimensions.

Understanding Zero Liquid Discharge (ZLD)

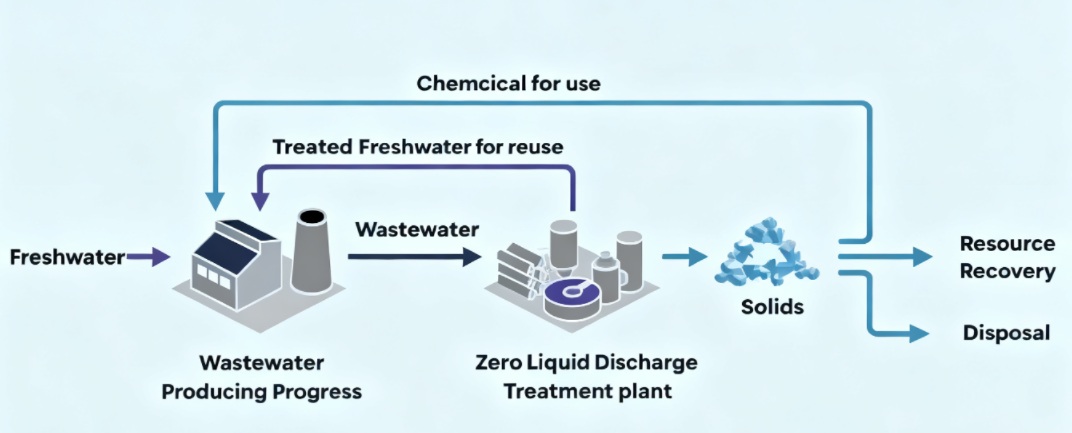

Like the name implies, ZLD refers to comprehensively treating industrial wastewater using various techniques and processes for water treatment to reach the objective of “full recovery, full utilization and no discharge” of wastewater. In this process wastewater is not discharged into the natural world in liquid form, but instead by purification, concentration, filtration, and other processes the wastewater is transformed to reusable clean water as well as recyclable or recyclable organic waste (such as minerals, salts such as salts, minerals, etc. ).

Essentially, ZLD is not a single technology but an integrated water treatment solution. It not only solves the environmental pollution problem caused by industrial wastewater, but also maximizes the recycling of water resources, reduces enterprises’ dependence on fresh water. Meanwhile, by recovering valuable substances (such as industrial salts, rare metals) from wastewater, it creates additional economic benefits for enterprises, serving as an important technical path balancing environmental, resource and economic benefits.

Core Processes of Zero Liquid Discharge

ZLD achieves its goal through a “step-by-step, progressive” process logic, which improves water quality and reduces wastewater volume incrementally. It consists of four key stages:

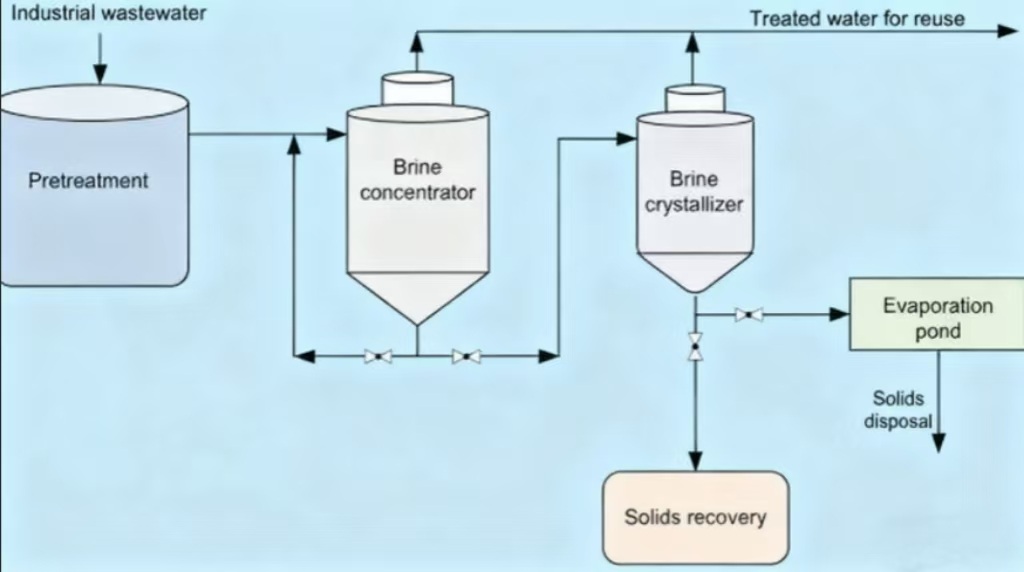

1. Pretreatment

As the foundation of ZLD, pretreatment eliminates impurities that might disrupt downstream equipment, providing qualified feedwater for advanced treatment. Key measures include: filtration via grilles or sedimentation tanks to remove suspended solids (preventing membrane clogging or evaporator scaling); chemical treatment with flocculants to separate colloids and oil; and pH/temperature adjustment for optimal efficiency of processes like reverse osmosis (RO) . Poor pretreatment causes frequent equipment failures and higher maintenance costs.

2. Concentration

This core stage reduces wastewater volume while recovering clean water. For medium-low salinity wastewater (<50,000mg/L), RO is used, achieving 80-90% water recovery by retaining salts. For hypersaline wastewater, evaporation technologies like multi-effect evaporators or mechanical vapor recompression (MVR) are preferred—MVR cuts energy use by recycling steam heat . The key is balancing water recovery and concentrate concentration.

3. Crystallization

For high-salinity concentrate (>100,000mg/L), crystallization achieves full solidification. Evaporative crystallization suits most cases by evaporating water to precipitate salts. Cooling crystallization is energy-efficient for temperature-sensitive salts (e.g., sodium sulfate) . Qualified salts are recycled; hazardous ones are properly disposed to avoid secondary pollution.

4. Water Recovery & Reuse

Recovered water from pretreatment and concentration undergoes advanced treatment (e.g., ion exchange) before reuse in industrial processes—cooling towers in power plants, equipment cleaning in chemical plants. This loop reduces fresh water procurement by over 50%.

Types of Zero Liquid Discharge Technology

The efficient operation of ZLD systems relies on the synergy of multiple technologies, which are categorized into three core types based on principles and application scenarios:

Membrane-based Systems

Membrane-based Systems that are based around “physical retention”, these systems employ membranes of various pores to separate water molecules from pollutants that have high efficiency and minimal energy consumption, mostly for concentration purposes:

Reverse Osmosis (RO) is a process that retains over 99% of the dissolved organics and salts, a key ingredient for moderately low salinity water.

Ultrafiltration (UF) Pore size 0.01-0.1mm eliminates suspended solids or colloids in RO prior treatment.

Nanofiltration (NF) is a method of trapping divalent ions (e.g., Ca, Mg) to decrease the hardness of water. They come with modular designs, however they incur the maintenance cost for cleaning and replacing membranes.

Evaporation and Crystallization

Evaporation and Crystallization focusing upon “thermal separation”, these are the most important factors to concentrating and solidifying hypersaline concentrate Multi-Effect Evaporator (MED) Serial evaporators increase the efficiency of heat, ideal for medium-scale usage.

Mechanical Vapor Recompression (MVR) reduces the energy consumption by 1/3-1/5 for traditional Evaporators, a common feature to large-scale processing.

Crystallizers: Guarantee the purity of crystals and uniformity. They are able to handle most hypersaline wastewater, but require an initial costs and a high energy use.

Electrodialysis & Ion Exchange

Based on “ion separation”, these are the most advanced treatments:

Electrodialysis (ED): Uses ion-exchange membranes for desalination, boosting RO recovery.

The Ion Exchange process: Reagents absorb certain Ions (e.g. the heavy metals) to make ultrapure water. They have a high efficiency in desalination however they consume chemicals (for regeneration of resin) and electricity, which serve as an auxiliary technology.unities by means of portable devices.

Core Benefits of Zero Liquid Discharge

ZLD is widely adopted across industries mainly due to its “environmental-economic-resource” triple benefits:

Environmental Sustainability

It is a fundamental step to eliminate industrial wastewater discharges, which prevents contamination of groundwater, soil as well as surface waters. In addition, water recycling decreases the extraction of freshwater, which eases the environmental pressures caused by water scarcity. For instance, the textile industry employing ZLD are no longer releasing the wastewater that contains dyes into the rivers, thereby protecting the ecosystems of aquatic life; chemical industries reduce the pollution of soil heavy metals and allow “green production”.

Resource Recovery

ZLD transforms the waste into a resource recovering valuable substances: Chemical industries extract industrial-grade salts (e.g. sodium chloride) to reduce the cost of raw materials mining companies retrieve high-value metals (e.g. copper or zinc) to market and food processing companies recover sugars and proteins for use in feed or fermentation. Chemical enterprises like this one, for example, can reclaim 11,000 tons of industrial sodium annually by using ZLD and saves more than 500 million yuan on procurement costs and decreasing the cost of disposal of solid waste.

Water Conservation

ZLD achieves over 90% water recovery (some over 95%), cutting freshwater use by 50%-80% in water-scarce areas. Thermal power plants reduce cooling tower freshwater makeup for cooling towers by 60%, saving over 10 million yuan yearly; oil industries reuse treated produced water, lowering groundwater reliance. This not only cuts water costs but also avoids production risks from water quota limits.

Industrial Applications of ZLD

With its strong adaptability, ZLD offers a variety of customized solutions for the characteristics of wastewater from different industries. ZLD is extensively used in a variety of areas:

Power Plants

Power plants (especially nuclear and thermal) are faced with the biggest challenges in wastewater including high-salinity cooling tower blowdown as well as desulfurization waste containing high-molecular weights as well as suspended substances. ZLD systems integrate pretreatment with reverse Osmosis, MVR evaporation, and crystallization. They reuse the cooling tower’s blowdown as cooling makeup water transform desulfurization waste into solid salts that can be used for safe disposal, and dramatically reduce the consumption of freshwater while meeting the requirements of the environment.

Chemical & Pharmaceutical Industries

The wastewater generated by these industries is a complex matter typically containing high concentrations of organics, salts, as well as harmful substances such as benzene compounds or antibiotic residues. ZLD systems employ advanced pretreatment for oxidation to eliminate organics, and is paired by membrane concentration as well as evaporative crystallization which results in zero discharge of liquids. They are also efficient in recovering industrial chemicals and high-value salts from wastewater, reducing costs for procurement of raw materials as well as increasing the efficiency of resource use.

Textile & Dyeing Industries

Textile dyeing wastewater, which contains huge amounts of dyes, chemicals and salts, is characterized by deep color, an extremely high pollution, and a low level of respect for traditional treatment. ZLD systems integrate decolorization/impurity-removal pretreatment with reverse osmosis and evaporative crystallization. They reuse treated water for the process of dyeing and washing, correctly remove crystallized salts, remove colored wastewater discharges directly from its source and decrease dependence on freshwater.

Conclusion

Zero liquid discharge is more than a water treatment technology; it is a key path for industrial enterprises to achieve green transformation. Through the model of “full wastewater recovery, resource reuse and zero pollution discharge”, it solves the dual dilemma of “high environmental pressure and high resource cost”, building a bridge for enterprises to realize the coordinated development of “ecological, economic and social benefits”. If you are struggling to build an efficient and compliant ZLD system, try purchasing at Molewater — its professional solutions can better meet your needs and help you easily achieve the goal of zero liquid discharge.