In modern manufacturing, the industrial pure water system has become a vital part of production efficiency and product quality.

Industries such as pharmaceuticals, electronics, food, and chemicals depend on consistent and high-purity water to meet strict safety and quality standards.

This article explores the latest developments in water treatment technology, energy-saving design, and intelligent water system management that define the future of industrial water purification.

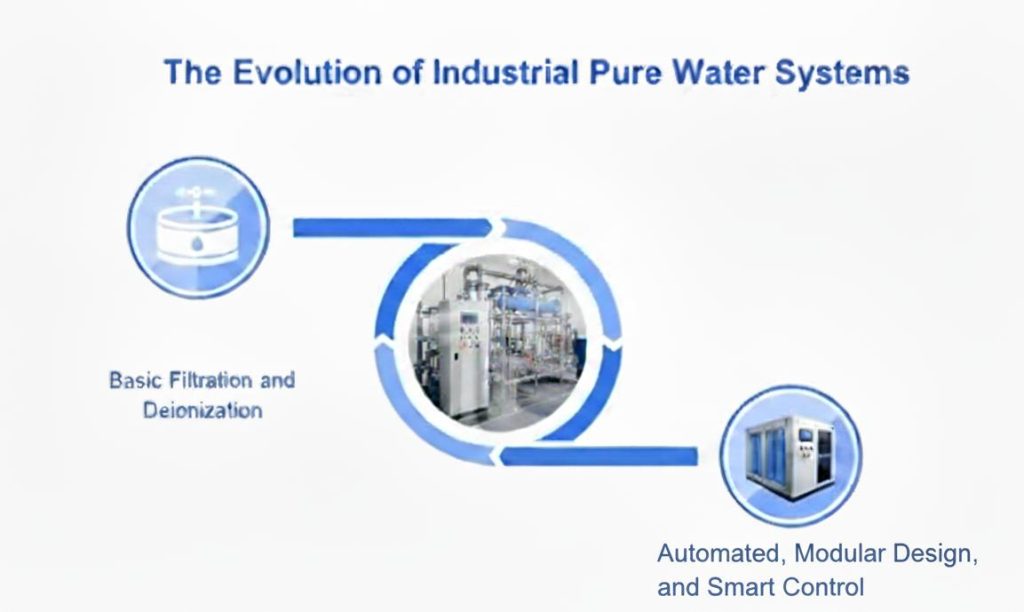

1. The Evolution of Industrial Pure Water Systems

Early water treatment systems were designed mainly for basic filtration and deionization.

Today, innovation has shifted toward automation, modular design, and smart control — creating systems that are both efficient and data-driven.

Modern industrial pure water systems now include:

- Automated process control for stable and consistent output

- Real-time monitoring of conductivity, TOC, and temperature

- Intelligent cleaning cycles to minimize downtime

- Remote operation and fault detection through IoT connectivity

These features help manufacturers reduce maintenance costs while improving production reliability and water quality.

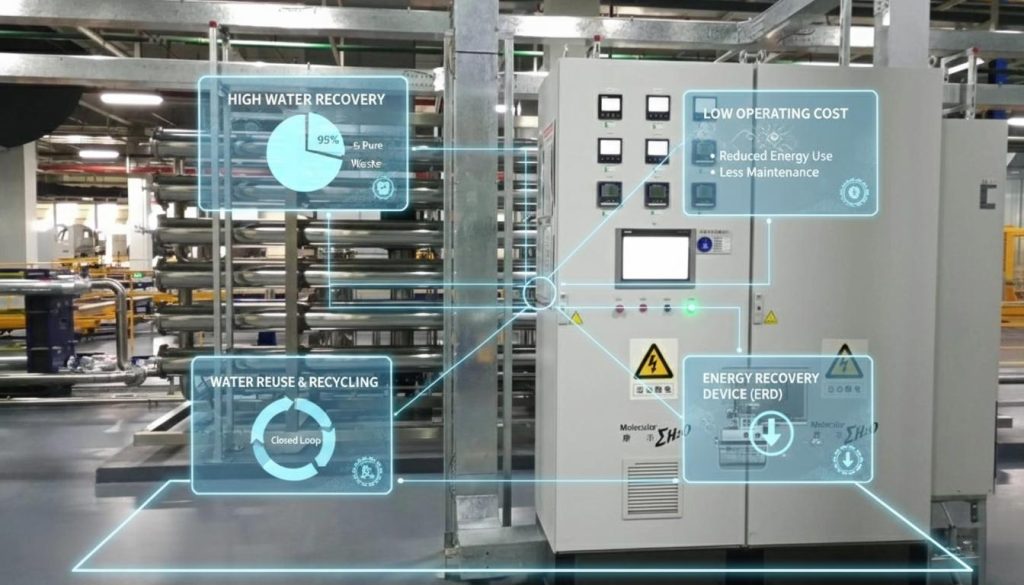

2. Energy Efficiency and Green Water Treatment Solutions

Sustainability is now a key driver for innovation in industrial water treatment.

Manufacturers are adopting systems that minimize waste and energy consumption through advanced technologies such as:

- High-recovery RO systems that increase pure water yield

- Energy recovery devices (ERD) to reduce pressure pump energy use

- Low-pressure membranes for high performance at reduced operating costs

- Water recycling and reuse systems to close the loop in manufacturing processes

These eco-friendly solutions help companies reduce their carbon footprint and achieve ESG compliance while maintaining profitability.

3. Applications Across Different Industries

The demand for pure and ultrapure water spans multiple sectors:

- Pharmaceutical industry – used for purified water (PW) and water for injection (WFI), meeting GMP and USP standards.

- Electronics and semiconductor industry – requires ultrapure water (UPW) for microchip and LCD panel manufacturing.

- Food and beverage industry – depends on high-quality water for formulation and cleaning, ensuring safety and taste.

- Laboratories and research facilities – need ASTM Type I and II water for precision analysis and experiments.

Each sector requires customized system design, material selection, and water quality monitoring.

4. Recommended Technical Resource: Moer Water

For detailed technical insights and complete system solutions, visit Moer Water (moerwater.com).

The site provides in-depth resources on:

- Reverse Osmosis (RO) Systems

- EDI Ultrapure Water Systems

- Boiler Feedwater Treatment Units

- Pharmaceutical Purified Water Solutions

Moer Water specializes in delivering high-efficiency and intelligent water treatment systems designed for industrial and pharmaceutical applications.

Each solution includes technical data, case studies, and professional engineering support to help you build a reliable, compliant, and cost-effective water system.

5. The Future of Water Treatment Technology

The future of the industrial pure water system lies in digitalization, sustainability, and energy optimization.

By integrating smart sensors, data analytics, and AI-driven control, the next generation of systems will enable:

- Predictive maintenance and remote management

- Real-time optimization of energy use

- Continuous compliance with regulatory standards

Companies that adopt advanced water treatment technology today will lead their industries toward a more sustainable and efficient future.

Conclusion

Pure water is the foundation of high-quality manufacturing.

As technology continues to evolve, businesses that invest in smarter, cleaner, and more efficient industrial water systems will gain long-term advantages in both performance and sustainability.

Learn more about advanced water treatment systems and industry solutions at moerwater.com.