Textiles-Soft water

From dyeing soft water to ZLD, we provide end-to-end water management for textile mills. Reduce costs, ensure compliance & enable recycling. Global remote support.

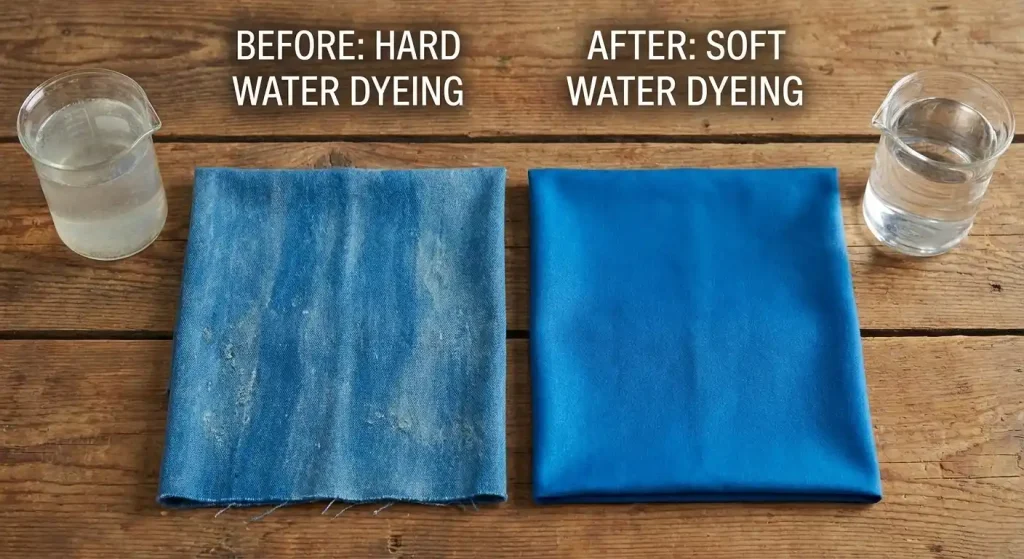

Is Hard Water Secretly Costing You Quality and Profit?

Turn Your Water into a Competitive Advantage

Our custom softening systems deliver consistent <30 mg/L CaCO₃ water for perfect dyeing, reduced chemical use & energy savings. Your soft water system is integrated into the Mole Cloud™. Receive real-time alerts on hardness levels, resin exhaustion, salt tank levels, and system performance. Our engineers can perform remote diagnostics and guide maintenance, ensuring zero interruption to your production.

- Improve First-Pass Dye Yield: Achieve consistent, reproducible colors, reducing re-dyeing and fabric waste.

- Reduce Chemical Consumption: Cut dye and salt usage by 5-15%.

- Lower Energy Costs: Prevent boiler scale, improving efficiency and saving 10-25% on fuel.

- Minimize Downtime: Predictive alerts and remote support prevent unexpected softener failures.

Discover Our Softening Solutions in Textiles

Centralized Wastewater & Water Recycling Plants

The workhorse for high-flow applications. Our automated systems provide a continuous supply of soft water with hardness typically < 5 mg/L as CaCO₃. Features redundant valves and remote monitoring for fail-safe operation.

Membrane Softening (Nanofiltration)

For the purest water needs or when dealing with high TDS feedwater. NF membranes remove hardness ions, organic matter, and color bodies, producing superior quality water for critical processes.

Request More Information

Contact Molewater for more information on available solutions.