Under the current background of increasingly strict environmental protection supervision, Zero Liquid Discharge (abbreviated as ZLD) has gradually become a realistic problem that industrial enterprises must face. Especially for highly polluting and water-consuming industries, they often face the challenge of striking a balance between compliance, cost and efficiency. Among the numerous solutions, MVR (Mechanical Vapor Recompression) is frequently mentioned. So, what exactly is it? What role does it play in ZLD? And is it suitable for your enterprise?

What is ZLD?

ZLD, the full name of which is Zero Liquid Discharge, means the zero liquid discharge system. As the name suggests, the goal of this technology is to fully recover and utilize or evaporate and concentrate the water in industrial wastewater without discharging any liquid into the external environment. This not only helps to reduce reliance on water resources, but also prevents pollutants from entering natural water bodies.

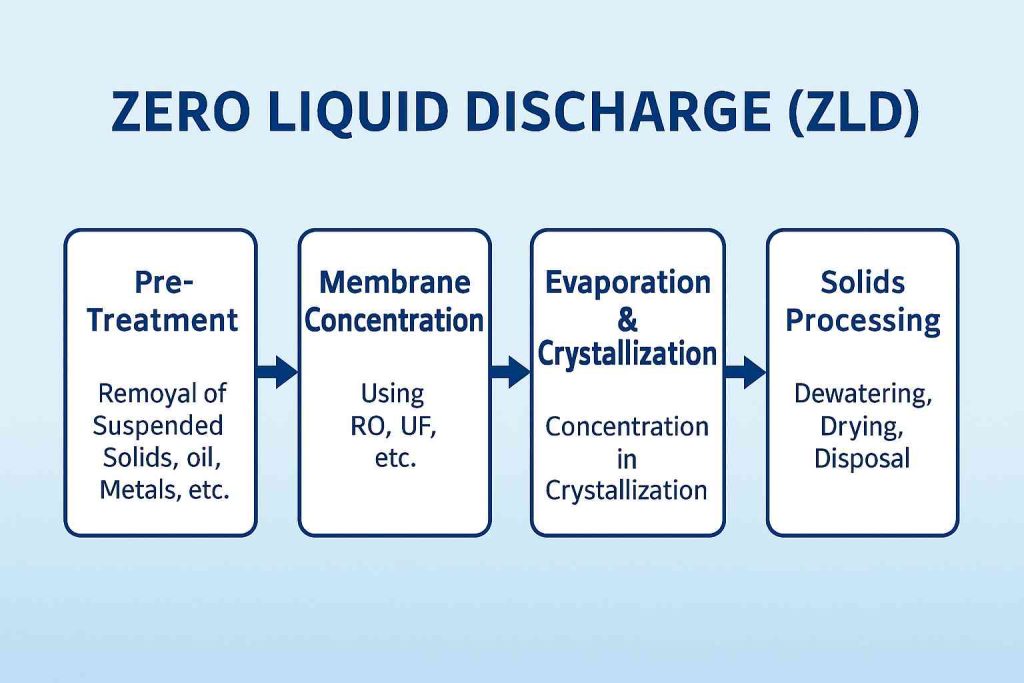

A typical ZLD system generally includes the following stages:

- Pretreatment: Remove suspended solids, oils, heavy metals and other impurities;

- Membrane concentration: such as reverse osmosis (RO), ultrafiltration (UF), etc., for the initial reduction of wastewater volume;

- Evaporation crystallization: Further concentrate the wastewater until crystalline salts or solid residues are formed;

- Drying and treatment: Solidify the crystalline substances to facilitate transportation or resource utilization.

Among them, the evaporation and crystallization stage is the most crucial and energy-consuming part, and MVR technology is one of the core devices that play a role here.

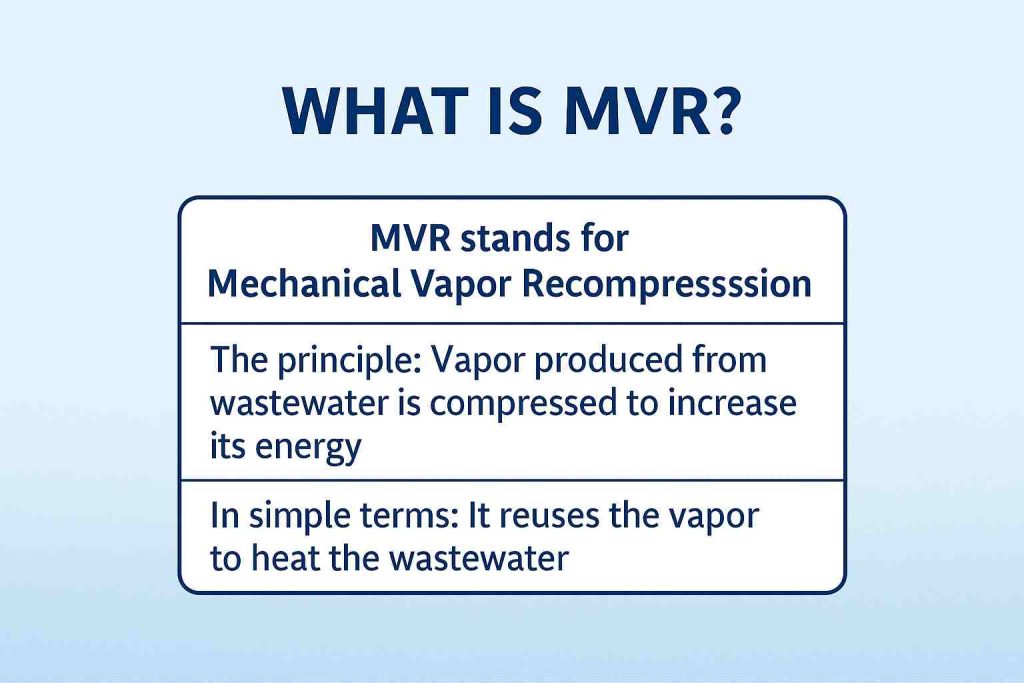

What is MVR?

MVR, namely Mechanical Vapor Recompression, is called mechanical vapor recompression in Chinese. The basic principle is as follows: When evaporating wastewater, a large amount of steam is produced. This steam could have been directly discharged, but the MVR system pressurizes it through a compressor, raising its temperature and pressure, and converting it into a heat source for reheating the wastewater, thus achieving the recycling of thermal energy.

The essence of this technology is to reduce energy consumption while enhancing evaporation efficiency. By constantly “recovering” and “reusing” steam, the MVR system significantly reduces the reliance of traditional evaporators on external heat sources.

The Role of MVR in the ZLD System

In the ZLD system, MVR is usually located after membrane concentration and is responsible for treating the remaining high-concentration wastewater, further concentrating it until it crystallizes or even solidifies. Due to the extremely high impurity concentration in this part of the wastewater, the effect of conventional treatment methods is limited. However, MVR can achieve more thorough reduction through efficient evaporation and the reuse of thermal energy.

Specifically, the main functions of MVR include:

- Rapidly reduce the volume of wastewater and shorten the treatment cycle;

- Increase the concentration rate and facilitate solid-liquid separation;

- Reduce overall energy consumption and save operating costs.

Why are More and More Enterprises Adopting MVR?

1. Significantly save energy and reduce operating costs

Traditional multi-effect evaporators (MED) rely on a large amount of external steam and have high operating costs. MVR can reduce energy consumption by 40% to 60% through the recycling of steam. For enterprises with large daily wastewater discharge volumes, the energy-saving effect is very considerable.

2. It has a wide range of applications and a high degree of automation

MVR can be applied to the treatment of high-salt and high-concentration wastewater in various industries, such as chemical engineering, pharmaceuticals, electroplating, food and beverage, etc. Meanwhile, the equipment operates with a high degree of intelligence, facilitating remote monitoring and automatic adjustment.

3. Facilitate environmental compliance and reduce policy risks

Against the backdrop of an increasing number of regions implementing the zero discharge policy for wastewater, MVR helps enterprises meet discharge standards, avoid environmental penalties, and establish a green image for their brands.

The Limitations and Risk Points of MVR

Although MVR has obvious advantages, it is not suitable for all scenarios. The following points need special attention:

High initial investment

The manufacturing of MVR equipment is complex and the purchase cost is relatively high, which poses a considerable pressure on small and medium-sized enterprises.

High requirements for pretreatment

If the wastewater contains a large amount of oil, suspended solids, and hardness ions, it is easy to cause scaling or clogging, affecting the service life and efficiency of the equipment. Therefore, it is necessary to do a good job in the front-end pretreatment.

High operation and maintenance technical threshold

It requires a professional operation management team to regularly clean and maintain the system to ensure its stable operation.

Is All Enterprise Suitable for Using MVR for ZLD?

The following self-check questions can help you make a preliminary judgment:

- Does the enterprise have a stable and relatively large volume of industrial wastewater?

- Is the wastewater high in salt content and rich in refractory components?

- Are you under pressure from government mandates or customer demands for zero emissions?

- Does it have a certain technical team or a reliable third-party operation and maintenance partner?

- Are there any front-end concentration devices such as reverse osmosis available to facilitate the integration of MVR?

If most of the above answers are “yes”, then MVR might be the key step for you to implement ZLD. If you are considering building or upgrading a ZLD system, feel free to contact us for professional assessment and solution suggestions. Molewater will help you achieve true zero emissions.

Final Thoughts

MVR is one of the core technologies in the ZLD system. With its energy-saving, efficient and environmentally friendly features, it has been widely applied in the field of industrial wastewater treatment. It is not a total perfect solution, but when dealing with high-concentration wastewater and high discharge standards, it is often the inevitable path to achieving ZLD.

Understanding the principle and function of MVR can help enterprises make more scientific and rational choices when building or renovating wastewater treatment systems. If your goal is zero emissions, energy conservation and consumption reduction, as well as long-term sustainable operation, MVR is worth your serious consideration.