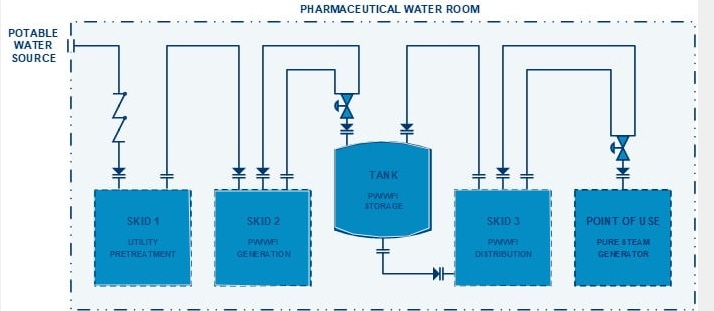

In industries such as food processing, pharmaceuticals, and healthcare that have strict requirements for aseptics, Pure Steam Generators (PSGs) are the primary equipment used to ensure safety in production. They convert purified feedwater into sterile, non-pyrogen free steam that meets strict standards like USP (United States Pharmacopeia), EP (European Pharmacopeia), and GMP (Good Manufacturing Procedures). The stability of PSG operation is crucial to ensure pharmaceutical sterilization, aseptic food filling, and disinfection of medical devices. This article will explain the PSG working principles from the fundamental variations in components, workflows, heating methods, and troubleshooting techniques to help industry professionals and technicians comprehend its operational process.

Critical Difference: Pure Steam vs. Industrial/Clean Steam

Many people are confused by pure steam with industrial steam and clean steam. But, improper use could result in serious issues such as production accidents and contamination of products. The main differences between the three lies in four areas that include feed water requirements and equipment materials purity standards, applications scenarios, as described in the following table:

| Comparison Dimension | Pure Steam | Industrial Steam | Clean Steam |

| Feed Water Requirement | Double-stage reverse Osmosis (RO) RO double-stage (particles that are ions, particles, and microorganisms filtered out) | Only water that is softened (calcium and magnesium ions eliminated) | One-stage RO water, or deionized |

| Equipment Material | 316L stainless steel (corrosion-resistant, no metal ion leaching) | Carbon steel that is normal (low cost, but susceptible to rust) | 304 stainless steel (medium cleanliness) |

| Purity Standard | Condensate is in compliance with Water for Injection (WFI) requirements | Contained impurities (e.g. iron, minerals, rust) and cannot touch the products directly | Condensate has no visible impurities but no pyrogen removal requirement; cannot be used for direct contact with pharmaceuticals |

Only after identifying these distinctions will the right steam type be determined in accordance with the needs. For instance pure steam should be employed in the production of injectables in the pharmaceutical sector. Using industrial steam, if used incorrectly, can cause contamination of drugs with microorganisms or heavy metals which can cause safety hazards.

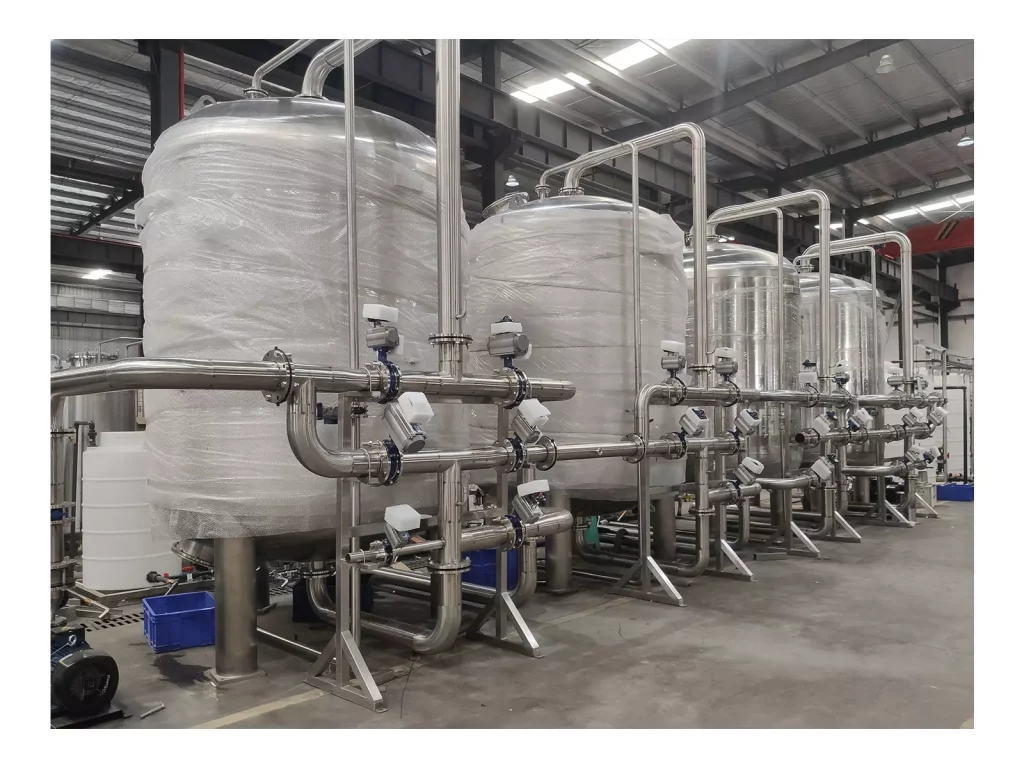

Key Components of a Pure Steam Generator

A pure steam generator’s stable operation relies on five core components, each ensuring steam purity and production capacity.

Feed Water Pre-treatment System

It purifies double-stage RO water by removing residual particles/micro-impurities for evaporation. It has three parts: a multi-stage pump (maintains 0.3-0.5MPa pressure for stable feed water supply), a two-stage preheater (uses waste steam condensate to heat water to 85-95℃, cutting energy by 20-30%), and a 0.22μm precision filter (prevents evaporator scaling by removing particles/colloids).

Evaporator

Then, as it is the “heart,” it heats the pre-treated water to a boil to create secondary steam. The most common models employ shell-and-tube heat exchangers that use falling-film evaporation. Industrial steam (shell side) and feed water (tube side) exchange heat through tubes’ wall (no contaminants). Water is sprayed with falling-film technology into 0.5-1mm films that adhere to the tube’s walls, increasing the exchange of heat by more than 30% while decreasing the risk of scaling.

Steam-Water Separation System

It removes droplets (with impurities/pyrogens) via three stages: gravity sedimentation (settles >10μm droplets), cyclonic centrifugation (flings 5-10μm droplets to separator walls), and a polypropylene/stainless steel demister (filters <5μm droplets/pyrogens). Output steam is free of obvious impurities, and condensate that is in compliance with WFI standards.

Control and Monitoring System

As the “brain,” it ensures stability and prevents cross-contamination. It includes a Siemens PLC (auto-adjusts processes, e.g., boosts heat recovery if water <85℃), sensors (monitor 0.6-0.8MPa shell pressure, ≥121℃ steam temp, triggers alarms), an online conductivity meter (shuts down if condensate >5.1 µS/cm), and double tube sheets (blocks steam-water contact if damaged).

Energy Recovery System

It uses evaporator waste steam condensate to preheat feed water and recycles it to the tank. It saves 15-20% water by recovering 100-500L condensate hourly.

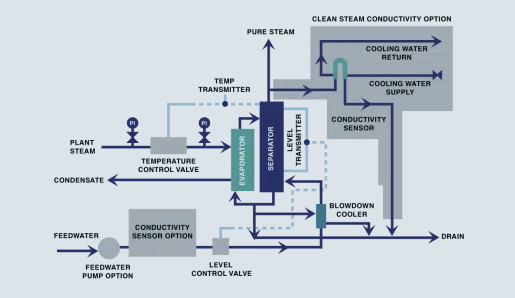

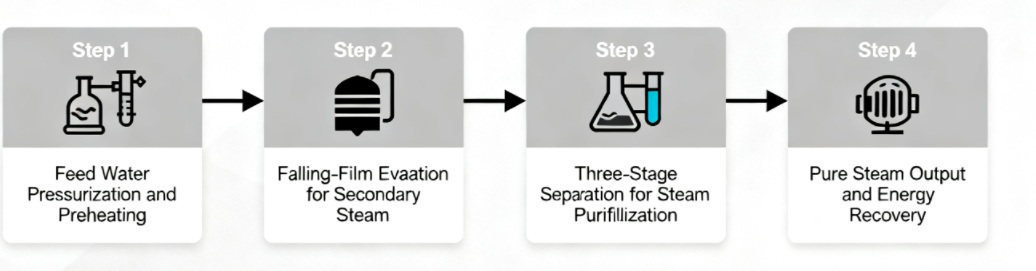

Step-by-Step Working Principle

Working Process of Pure Steam Generators

After understanding the core components, we break down the pure steam generator’s workflow into four steps, clearly showing the conversion from feed water to pure steam.

Step 1: Feed Water Pressurization and Preheating

Qualified double-stage RO water first enters the feed water pre-treatment system. Filtered by the precision filter, it is pressurized to 0.3-0.5MPa by the multi-stage pump and delivered to the two-stage preheater. The preheater uses heat from waste steam condensate to raise the feed water temperature to 85-95℃. This step reduces the subsequent evaporator’s heating load and improves overall efficiency—using room-temperature water directly would require more industrial steam for boiling.

Step 2: Falling-Film Evaporation for Secondary Steam

Preheated feed water is evenly sprayed onto the evaporator’s tube-side inner wall via a water distributor, forming a thin water film. Industrial steam (130-140℃, 0.6-0.8MPa) in the shell side exchanges heat with the water film through the tube wall, quickly heating it to 105-110℃ (boiling point) to form secondary steam. The fast-flowing water film and large heat exchange area enable high efficiency, generating 50-2000kg of secondary steam per hour (depending on equipment capacity).

Step 3: Three-Stage Separation for Steam Purification

Secondary steam enters the steam-water separation system and undergoes three separation stages in sequence. Gravity sedimentation removes droplets over 10μm in diameter. Cyclonic centrifugation eliminates 5-10μm fine mist. A demister filters droplets smaller than 5μm and pyrogens. After separation, the steam reaches ≥99.5% dryness and <3.5% non-condensable gas content, fully meeting pure steam standards.

Step 4: Pure Steam Output and Energy Recovery

Pure steam (≥121℃, ≥0.1MPa) is transported via pipelines that are specifically designed for sterilization machines (e.g. bioreactors, bioreactors, filling lines that are aseptic) to sterilize equipment or products. In the meantime, industrial steam on the evaporator’s shell transforms to condensate (120-130℃) after the release of heat. Condensate is then sent to the preheater as a heating source to recover energy. The excess condensate is then recycled into the tank for feed water to further reduce the use of water and energy.

Heating Methods: Steam vs. Electric

Pure steam generators generally come in two kinds: steam-heated and electric-heated. They have distinct distinctions in the source of heat and efficiency, capacity and applications.

| Dimension | Steam-Heated | Electric-Heated |

| Heat Source | Factory industrial steam | Steel electric heating tubes in stainless steel |

| Efficiency | High (20-30% energy savings through waste heat recycling) | Medium (no recuperation, only direct use of electricity) |

| Capacity | 50-2000kg/h (large) | 10-500kg/h (small-medium) |

| Application | Large food and pharmaceutical manufacturing facilities | Small sterile lines, labs and hospital disinfection rooms |

For instance, big pharmaceutical facilities require 24/7 capacity steam (e.g. 1000kg/h) and should choose models with steam heating and hospitals with smaller needs (e.g. 50kg/h) prefer models that are electric-heated to make installation simple.

Common Troubleshooting

During operation, pure steam generators may face issues like substandard steam purity, reduced capacity, or cross-contamination risks. Timely troubleshooting ensures continuous production.

Issue 1: Substandard Steam Purity (Excessive Conductivity/Unqualified Endotoxin)

The reason is a clogged demister (impurities decrease filtering) or low purity of the feed water (substandard RO water from a double-stage system or damaged filter elements) or a malfunctioning separation system (damaged the cyclone separator).

Solutions: Replace demisters each 3 to 6 months; test RO’s condition and replacement of the filter elements (1-2 months’ lifespan) Inspect and repair the cyclone separators.

Issue 2: Reduced Capacity (Insufficient Steam Output)

The cause is Evaporator Scaling (impurities hinder heat exchange) Wearing multi-stage pumps (low flow/pressure) and low industrial steam pressure (<0.6MPa for models with steam heating).

Solutions: Acid-clean evaporators (5-10% citric acid, 6-12 month intervals). Replace pump components to ensure 0.3-0.5MPa and reduce steam pressure 0.6-0.8MPa or clean pipelines.

Issue 3: Cross-Contamination Risk

Causes: Damaged double tube sheets (cracks from high temperature/pressure), aging non-PTFE seals (leaks).

Solutions: Inspect the sheets of tube each quarter (replace the sheets and check for leaks at 1.0MPa over 30 minutes) and upgrade with sanitary seals made of PTFE, and replace every six months.

Summary

Pure steam generators are considered to be an essential “core guarantee” for aseptic production. The principle behind their operation rests on four main links including pre-treatment → evaporation → separation → output, with essential components collaborating to guarantee the purity of steam and meet the standards.

Only when you are aware of their fundamental working principles and maintaining important points, can a stable operation be assured, ensuring solid support for production in the food, pharmaceutical and healthcare industries and avoiding interruptions in production or accidents involving safety of products caused by equipment problems. If you’re in search of an appropriate pure steam generator, you can get one from Molewater!