Water is an essential material in the pharmaceutical industry. Its purity has a direct impact on drug quality, compliance, and patient safety. Water quality is critical for many processes, from raw material cleaning to packaging and equipment sterilization. As a specialist in pharmaceutical water solutions, Molewater provides purified water, water for injections, hemodialysis water, and pure steam, precisely meeting the industry’s diverse needs. Below is our summary of these water types to help you identify the right grade and matching Molewater system.

Purified Water

In the pharmaceutical industry, purified water is the standard grade of water. Purification is a process that removes microorganisms, suspended solids, and other contaminants from raw water by using chemical, physical or biological methods. The main indicators are conductivity ≤4.3μS/cm (25℃), TOC(total organic Carbon) ≤0.5mg/L, microbial limit ≤100CFU/mL, and freedom from heavy metals, pathogenic bacteria, and pyrogens.

It is a better alternative to drinking water because it removes impurities which can affect the stability of drugs. It is cheaper to produce than water for injections because it doesn’t require sterility.

Applications suitable for Purified Water

- Oral dosage form: Used to clean raw materials, batch, granulate, and coat tablets, capsules and oral solutions. It is used to remove dust/pesticide residues and act as a solvent in order to prevent impurity-related issues such as taste or stability.

- Topical preparations: Suitable for products such as ointments and creams. They also meet the microbial control requirements to prevent skin irritation.

- API and excipient processing : Used in API refining (crystallization), washing, and excipient dissolution/mixing (starch, milk, magnesium stearate, etc.) to improve product purity and effectiveness.

- Use of laboratory & equipment: Sample dilution and calibration, QC lab reagents preparation, daily cleaning and disinfection of reactors, mixers and pipelines.

- Non-sterile Medical Devices: Removes oil, dust and microorganisms from disposable masks and dressings.

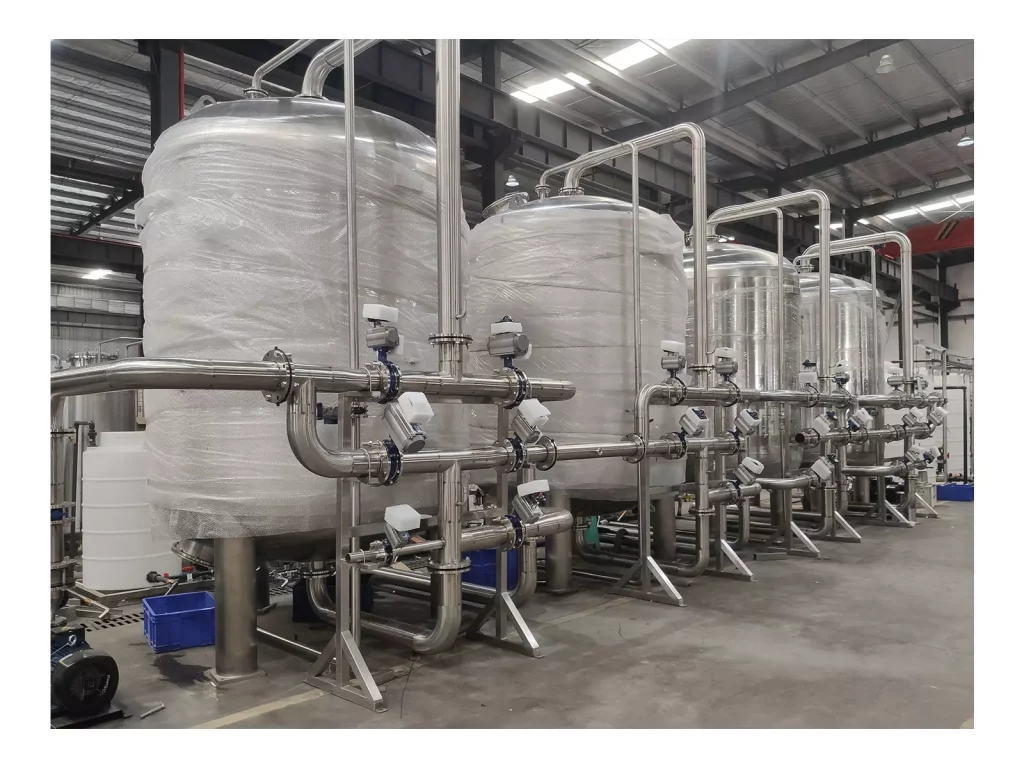

Molewater Solution

Molewater offers a complete “pre-treatment + core treatment + post-treatment” process. The pre-treatment protects the core equipment by using activated carbon adsorption and quartz sand filtering. Core treatment uses RO (imported membranes 99.5% desalination), and EDI with conductivity (conductivity ≤1μS/cm). The post-treatment process includes UV disinfection, precision filtration and precision filtering.

It is equipped with an intelligent system that allows real-time monitoring and compliance with GMP standards. Modular design allows for flexible capacity (50L/h–10m³/h), and can save 30% on water and electricity when compared with traditional systems.

Water for Injections (WFI)

WFI is a high purity pharmaceutical grade water that builds on purified drinking water by removing pyrogens and microorganisms. It also meets the strict “sterile, low TOC, low pyrogen” standards. According to pharmacopoeial standards, the key indicators are conductivity ≤1.3μS/cm (25℃), TOC≤0.2mg/L and a microbial limit of ≤10CFU/100mL.

Pyrogens are dangerous–injections can cause shock, fever or even death. WFI is produced using RO+EDI or distillation processes that are fully sterile to prevent secondary contamination.

Applications suitable for WFI

- Injections: To prepare, dissolve, or dilute injections (normal salt, antibiotics and vaccines), as well as lyophilized powders such penicillin and biological products.

- Ophthalmic preparations: Available in eye drops, gels, and ointments. They protect the fragile mucosa of the ocular surface from infections such as conjunctivitis.

- Sterile medical device: Final rinsing invasive tools such as syringes or stents to remove microorganisms and residues. This prevents in-vivo infection.

- Biological products: Meets sterility/pyrogen-free needs for vaccines, antibodies, and blood products, safeguarding active ingredients.

- Sterile excipients: Used to make injectable excipients for injection formulation (mannitol, glucose).

Molewater Solution

The system is compliant with GMP and USP standards. It features a complete process design, including “purified-water pretreatment + multieffect distillation + sterilized storage & distribution.” The core distiller uses high-temperature distillation(>100℃)to eliminate pyrogens/microorganisms, with a 316L stainless steel tower(Ra≤0.4μm) to avoid adsorption. Nitrogen-protected storage tanks are used with SIP to sterilize regularly. The circulation system ensures a flow rate of ≥1m/s (no dead-ends) and includes online monitors that measure conductivity, TOC and temperature. If standards are not met, automatic alarms will be triggered and an emergency declared.

Hemodialysis water

Hemodialysis Water is a pharmaceutical water that has been specially designed for hemodialysis and other treatments. Its quality is directly linked to the safety of patients with kidney disease. Impurities in water (heavy metals and microorganisms as well as disinfectant residues), can cause complications during hemodialysis. Its quality standards are very strict. The key indicators are conductivity ≤10μS/cm (25℃), TOC≤1mg/L, microbial limit of ≤100CFU/mL, endotoxin of ≤0.25EU/mL and strict limits for harmful substances such as lead ≤0.5μg/L, mercury ≤0.1μg/L, chloramine ≤0.1mg/L, nitrate ≤2mg/L. Unlike WFI, it doesn’t require sterility but demands ultra-low microorganisms/endotoxins and electrolyte removal.

Applications suitable for Hemodialysis Water

- Hemodialysis: Used to prepare dialysate in order to remove waste (urea and creatinine), excess water, and replenish electrolytes. Substandard water can cause nausea, hypotension or long-term complications such as anemia.

- Peritoneal dialysis: For formulating peritoneal dialysate–impurities are absorbed via abdominal capillaries, requiring the same standards as hemodialysis water.

- CRRT: For severe kidney patients (24 hour continuous treatment), requiring higher purity/stability in order to avoid impurities accumulation.

- Cleaning of dialysis equipment: Removes blood and residues from dialyzers/dialysis machines to prevent cross infection.

Molewater Solution

Molewater’s solution is tailored to the specific needs of each customer. It includes “pretreatment, deep purification, disinfection, and circulating storage”, ensuring a stable, safe quality of water.

Pretreatment is achieved by using multi-media filtering, softening and chloramine-specific active carbon to remove hardness and disinfectant residues. Deep purification adopts double-stage RO + EDI–double RO removes heavy metals/electrolytes/microorganisms, while EDI ensures conductivity compliance. Disinfection uses UV (which kills microbes quickly) and ozone, which removes organics (and decomposes into oxygen without leaving residues). The circulating storage system uses sealed tanks and pumps to stop microbial growth. It also disinfects automatically. The system is user-friendly, easy to maintain, and equipped with real-time monitoring/alarm–stopping water supply immediately if standards are exceeded to protect patients.

Pure Steam

Pure steam is impurity-free steam distilled from purified water or WFI, with quality standards aligned to WFI—core requirements are “pyrogen-free, sterile, and low impurities.”

Unlike industrial steam, it requires full removal of raw water impurities to avoid equipment deposition or drug contamination during sterilization. Its dryness and saturation are strictly controlled for uniform, stable sterilization, making it a core medium for ensuring drug sterility in pharmaceutical aseptic equipment sterilization.

Applications suitable for Pure Steam

- Equipment Sterilization – This method is used for sterilizing production equipment (reactors/mixers/pipelines/filters, filling machine, etc.). By heating the equipment at 121 ℃ for 30 minutes. It kills microorganisms and spores.

- Sterilization of Drug Containers – This process sterilizes containers such as capsules, vials and ampoules to prevent contamination.

- Medical device sterilization : Recommended to sterile medical instruments (syringes, surgical instruments, etc.) due to its high penetration, effectiveness and lack of residues.

- Culture Medium Sterilization: Sterilizes microbial testing media to avoid interfering with test results

Molewater Solution

Centered on “high purity, stability, and safety,” the system adopts a full-process design: “purified water + pure steam generator + steam distribution + condensate recovery.”

The stainless steel generator uses electric/steam heating to produce steam via distillation (dryness ≥99.5%, saturation ±2℃). The 316L stainless steel distribution pipeline has a polished inner wall (no dead ends) to prevent adsorption and bacterial growth, supporting SIP. The condensate recovery system reuses treated water, saving resources.

Compliant with GMP, it features online monitors for real-time tracking of temperature, pressure, and purity, with automatic data recording. Customizable pressure/temperature adjustments adapt to different scenarios, plus self-diagnostic and automatic protection functions that shut down immediately in case of abnormalities to ensure safety.

Reference for Common Application Scenarios

| Application Scenarios | Recommended Water Grade | Core Reasons |

| Production of oral tablets and capsules | Purified Water | No sterility required; only microbial and impurity control needed, with high cost-effectiveness. |

| Production of injections and vaccines | Water for Injections (WFI) | Directly injected into the human body; requires sterility and pyrogen-free properties to meet strict pharmacopoeial requirements. |

| Hemodialysis treatment | Hemodialysis Water | Long-term contact with patients’ blood; strict control of heavy metals and microorganisms is essential. |

| In-situ equipment sterilization (SIP) | Pure Steam | Needs to be pyrogen-free and sterile to ensure sterilization effect without equipment contamination. |

| Cleaning of non-invasive medical devices | Purified Water | Removes impurities and microorganisms to meet hygiene standards. |

| Sterilization of invasive medical devices | Pure Steam | Requires sterility and no residues to ensure clinical use safety. |

| Laboratory reagent preparation | Purified Water | Eliminates impurity interference to ensure accurate test results. |

| Production of ophthalmic preparations | Water for Injections (WFI) | Ocular mucosa is sensitive; requires sterility and pyrogen-free properties to avoid infections. |

Summary

With years of in-depth experience in the pharmaceutical industry, Molewater has developed full-process customized solutions tailored to the application scenarios and compliance requirements of various pharmaceutical waters. Covering from pretreatment to end-use water, as well as equipment supply and operation and maintenance services, it fully meets enterprise needs. Whether for capacity upgrades of small and medium-sized pharmaceutical enterprises or compliance transformations of large pharmaceutical companies, Molewater can provide suitable products and services, helping enterprises select the right pharmaceutical water grade, reduce production costs, and improve product quality.