In the food industry, water is far more than just a raw material. It is related to the taste, hygiene and safety of the product, and even affects the stability of the entire production line. As consumers’ demands for quality continue to rise, an increasing number of food manufacturers are beginning to pay attention to how to enhance water quality and production efficiency through efficient RO (reverse osmosis) systems.

However, there are numerous types of RO systems on the market with different performance indicators. So, how can one select the one that truly suits them?

Why Should The Food Industry Carefully Choose RO Systems?

In the food processing, water is widely used for cleaning, blending, steaming and cooling. If the water quality does not meet the standards, it may not only affect the flavor of the product but also lead to bacterial growth, increasing the risk of food safety.

Although ordinary RO systems can remove impurities, they often have deficiencies in terms of energy consumption, recovery rate, and operational stability. What the food industry needs is not only “clean water”, but also an overall solution that is efficient, stable, energy-saving and meets food-grade standards.

It can be said that the selection of an RO system is not merely a technical decision, but also a reflection of an enterprise’s quality and brand image.

How to Check Whether an RO System is Efficient?

When faced with a wide variety of RO devices, the criteria for judgment can actually be traced. The following key indicators can help enterprises quickly determine whether the system is efficient and reliable.

1. Check the purification capacity

The desalination rate and water recovery rate of the system directly reflect its performance. High-efficiency RO systems typically achieve a desalination rate of over 99% while ensuring a high water recovery rate, thereby minimizing waste while maintaining purity.

2. Check the energy consumption level

Energy-saving RO systems often employ highly efficient membrane elements and energy recovery devices, which can significantly reduce power consumption under the same water production volume. In the long term, this part of the energy-saving cost can significantly reduce operating expenses.

3. Check the operational reliability

Food factories usually need to operate continuously. The RO system must have the ability to resist pollution and scaling to ensure stable water production for a long time.

4. Consider the convenience of maintenance

Efficient systems often feature an automatic cleaning (CIP) function, making the replacement of membrane elements simple and requiring less manpower for daily maintenance.

5. Check hygiene and certification

Food-grade RO systems must comply with certification standards such as NSF, FDA, and ISO22000 to ensure the safety and reliability of the effluent and prevent secondary pollution.

6. Check the customization compatibility

The raw water conditions of different food enterprises vary greatly – from tap water to groundwater, the water quality components are all different. An excellent RO system should be flexibly configured according to water quality characteristics, production scale and production capacity requirements.

What be Considered When Choosing an RO System?

When choosing an RO system, it is not merely about “whether the parameters are high or not”, but rather about evaluating the overall performance from multiple dimensions.

- Performance dimension: Focus on the desalination rate, recovery rate and operational stability of the system.

- Economic dimension: Assess the long-term costs brought about by energy consumption, maintenance and membrane lifespan.

- Sustainability dimension: The highly efficient RO system can significantly reduce wastewater discharge and meet environmental protection requirements.

- Service dimension: Outstanding brands usually offer comprehensive after-sales support and local technical services to ensure worry-free long-term operation.

In other words, a truly efficient RO system should not only save water and electricity, but also be stable, reliable, easy to maintain, and enable enterprises to benefit from long-term operations.

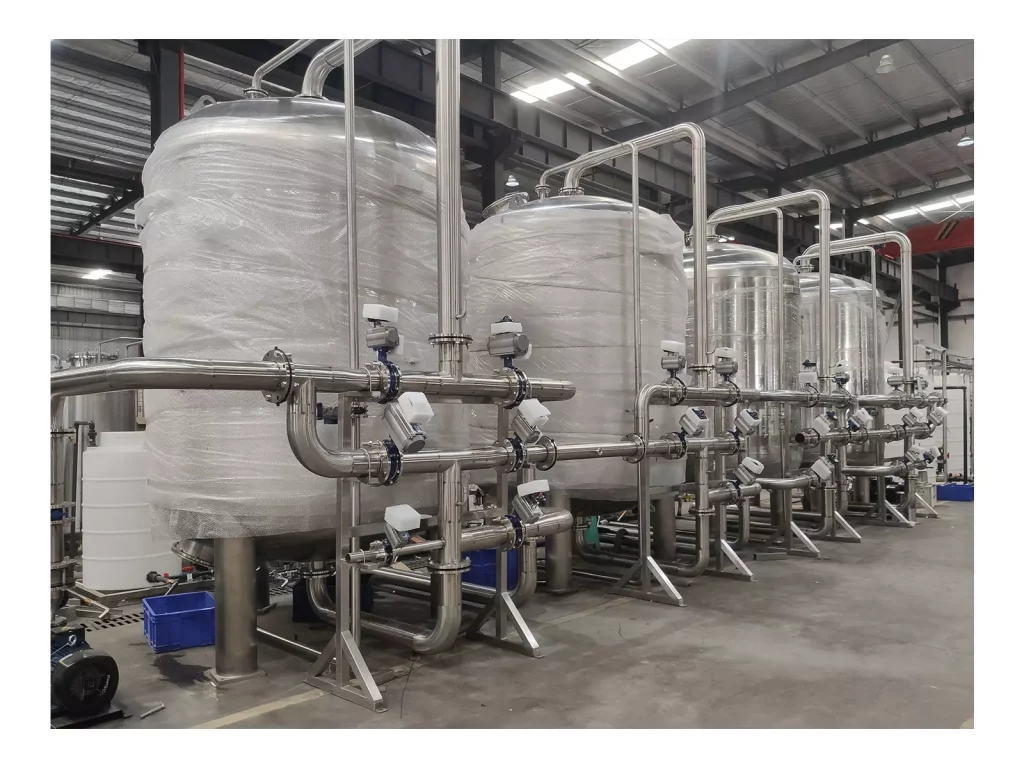

Why Molewater RO System is An Ideal Choice For The Food Industry?

In the actual operation of many food factories, the investment in RO systems is often regarded as a cost, but in the long run, it is more like an energy-saving investment.

An efficient RO system can usually recover its cost within one to two years by reducing energy consumption and wastewater discharge. From then on, the energy and maintenance costs saved every day will be transformed into real profits.

In addition, reducing the discharge of waste liquid not only lowers the cost of sewage treatment but also helps enterprises maintain an advantage in environmental supervision. This intangible brand bonus is also an important reason why many enterprises choose efficient RO systems.

For food manufacturing enterprises that pursue high quality and high efficiency, Molewater RO system is undoubtedly a reliable choice.

High recovery rate and low energy consumption design: Maintain stable purification capacity while saving energy.

- Zero Liquid Discharge (ZLD) solution: Effectively reduces wastewater and helps enterprises achieve green production.

- Intelligent monitoring system: Real-time monitoring of water quality and operational status to ensure production safety.

- Customized configuration: Based on the quality of the raw water and process requirements, a system solution is tailor-made.

These characteristics have enabled Molewater to accumulate rich experience in the fields of food processing, beverages, dairy products, etc., and have won the long-term trust of industry customers.

Final Thoughts

Choosing an RO system is not only for obtaining pure water, but also for ensuring food quality, enhancing production efficiency and achieving sustainable development of the enterprise.

In this era where quality prevails, an efficient and reliable RO system is precisely the solid backing for the steady progress of the food industry.

Molewater will continue to provide professional, energy-saving and sustainable water treatment solutions for the food industry, making every drop of water the starting point of food safety and brand trust.