Pure water is getting more easy, advanced water treatment techniques are no longer considered luxury but essential. The growth of the population, industrial expansion as well as environmental pollution have stretched conventional methods of water filtration to the limit. Many struggle to eliminate tiny contaminants such as pathogens and bacteria that can harm the health of people. Ultrafiltration, a cutting-edge membrane separation method has been the mainstay of modern wastewater and water treatment. This article will explain ultrafiltration, it’s parts and working principles, as well as its advantages, and applications, helping you understand why it’s a game-changer for clean water.

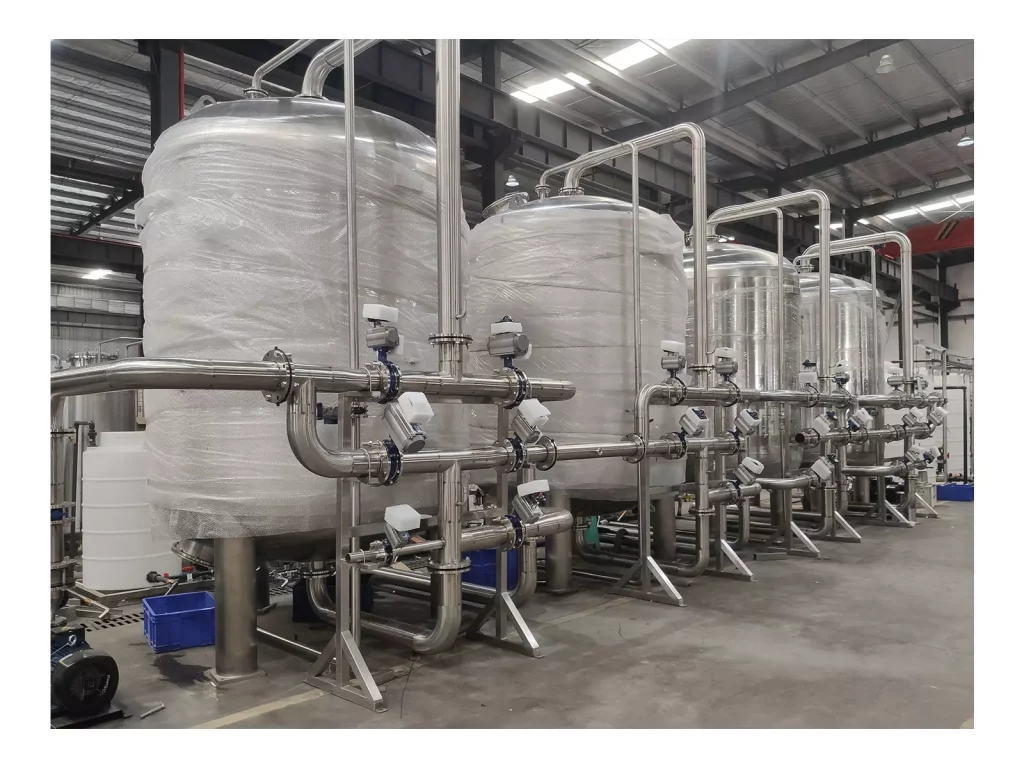

Ultrafiltration System Components

The performance of an ultrafiltration system is dependent on its components that are is designed to work together to effectively purify water.

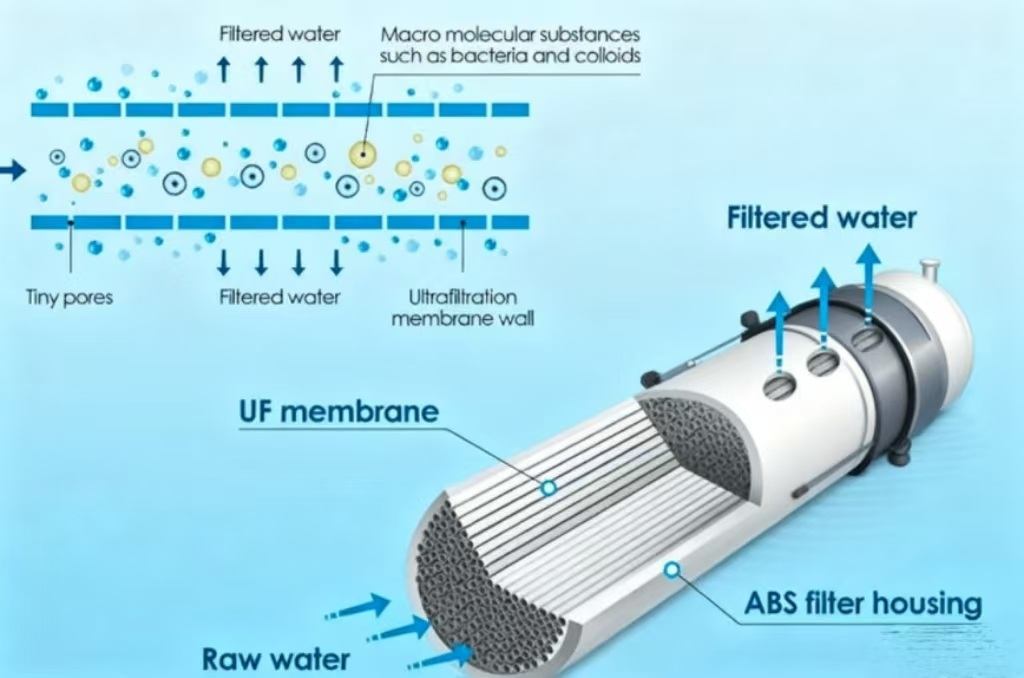

The ultrafiltration membrane is the heart of the whole system. Made of components such as PVDF (Polyvinylidene Fluoride), PAN (Polyacrylonitrile) as well as PES(Polyethersulfone). Each material has its own specific requirements.

- PVDF membranes stand out due to their resistance to chemicals and pollution which makes them perfect for the treatment of industrial wastewater as well as municipal sewerage.

- PAN membranes offer low cost and high performance, backed by hydrophilic properties. They are ideal for household or commercial use where the levels of pollution are quite low.

- PES membranes have the highest flux and stability and are able to meet the requirements for high-efficiency in manufacturing lines for industrial use.

The next are membrane modules which affect the system’s effectiveness and capacity.

- Fibers made of hollow stand out due to their larger area of membranes relative to their volume of use which is ideal for large-scale construction projects such as municipal water treatment plants as well as industrial installations.

- Flat sheet module have a straightforward structure, and are paired with simple cleaning capabilities, making them perfect for smaller-scale projects such as household water purifiers as well as compact commercial installations.

- Tube modules excel for handling high-viscosity industrial water, like that created by food processing facilities due to their high pressure resistance and robust anti-pollution capabilities.

To complete the system, you will need additional apparatus.

- Powerful pumps are used in industrial applications that require massive treatment, whereas low-power models are suitable for home systems that are designed to be used on a smaller scale.

- Systems for backwashing are essential in ensuring membrane performance; they automatically clean membrane’s surface at regular intervals to avoid clogging. This aids in maintaining a steady efficiency of filtration as time passes.

- Systems for controlling are adapted to the requirements of various customers: municipal and industrial installations rely on full automation for operation that is completely unmanned which streamlines large-scale water treatment processes while small and household businesses make use of user-friendly semi-automated systems that are able to balance functionality with simplicity of use.

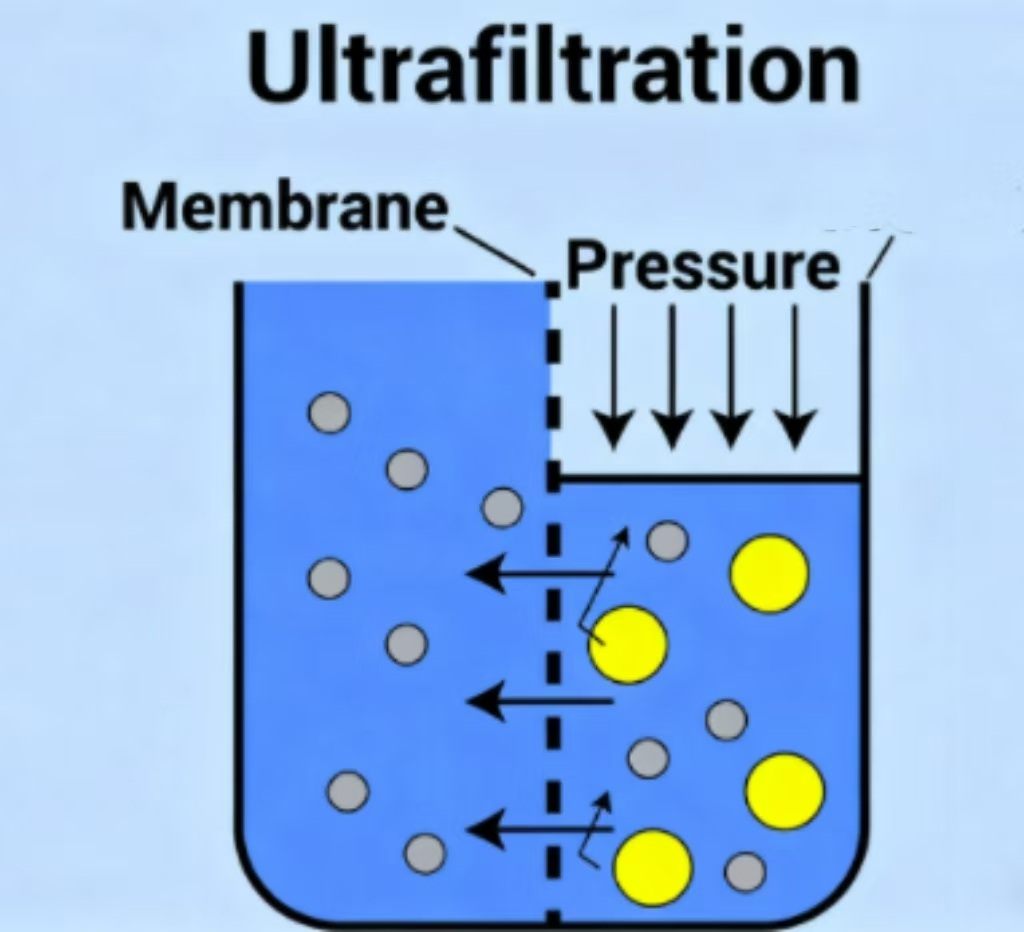

Working Principle of Ultrafiltration Process

In its essence, ultrafiltration operates on a basic but powerful concept of pressure-driven physical separation. Contrary to chemical treatment techniques which rely on additives, ultrafiltration makes use of membranes that have very tiny pores (0.01-0.1 micrometers) to remove contaminants. They are small enough to hold pathogens, bacteria, and suspended solids, yet sufficient to allow liquids and minerals that are beneficial (like magnesium and calcium) flow through. This distinguishes it from reverse osmosis which can remove even minerals and ions.

The main advantages of this method over traditional filtration are obvious:

High reliability: Get rid of more than 99% of bacterial and pathogens. This is a crucial element for drinking water that is safe or industrial processes water.

Variability: Can be used to adapt to different water sources, ranging from water from industrial and municipal raw water as well as household tap water.

Scalability: It works flawlessly to work with small scale (e.g. an individual’s water purifier) as well as large-scale (e.g. the municipal water treatment plant) applications.

Essential Differences iUltrafiltration Process in Water Treatment

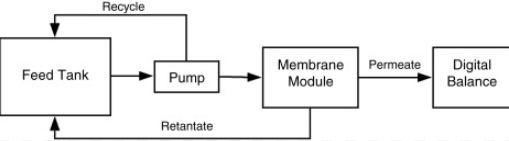

Ultrafiltration is a process that takes place in three major stages that are each designed to provide the safest, clean water output.

Step 1: Pre-Treatment – Preparing Water for Filtration

The purpose of pretreatment is to minimize membrane fouling by removing impurities that may block pores. The procedure varies based on the water source: For industrial high-turbidity water, grilles first clear large particles, followed by sedimentation tanks that settle suspended solids and flocculation to remove colloids. For municipal water ,conventional flocculation and sand removal decrease organic matter as well as suspended particle. For domestic or commercial water use Simple PP cotton pre-filter eliminates visible rust and sediment.

Step 2: Core Filtration – The Purification Stage

Here is where magic occurs. Pressure pumps force liquid through the membrane of ultrafiltration, and then separate the two streams:Permeate Water that is clean and mixed with minerals of small molecule that form its final form. Contaminants, such as pathogens and bacteria, released into the environment as “concentrated water.”

Two operating modes are utilized:

Cross-flow filtration: A portion of the water flow through the membrane while it flows across the surface to remove contaminants. This is ideal for continuous industrial production.

Dead-end Filtration: The entire of the water goes through the membrane with periodic backwashing – ideal for homes small-scale businesses, households, and small-scale municipal usage.

Step 3: Post-Treatment & Membrane Maintenance

Post-treatment improves the water’s intended purpose:

Water for drinking: ultraviolet or Ozone disinfection kills all remaining pathogens.

Ultrapure industrial water: Combines with reverse osmosis for removal of the ions needed for high purity (e.g. electronics manufacturing).

Municipal water reclaimed pH adjustment makes sure it is safe for irrigation and urban greening.

Maintenance of the membrane is vital to long-term viability.

Physical cleaning Backwashing regularly (using clear permeate for flushing membranes reverse) and air-washing remove any surface impurities. Every 3 to 6 months citric acid (for decaling) as well as sodium hypochlorite (for sterilization) deep-clean membranes to improve the flow.

Click here to learn how it works and where to use it.

Benefits of the Ultrafiltration Process

Ultrafiltration systems are now popular in various industries because of their superior rejection of impurities as well as their cost-efficiency and flexibility that include the following advantages:

High-quality, potable water that is consistent.

The primary function for ultrafiltration is to eliminate microscopic solids suspended in the water. Whatever the concentration of the feed water or composition, these systems guarantee the highest quality of filtration, free of suspended particles with an average molecular weight of 20nm. Ideal for saltwater treatment, wastewater treatment desalination and water filtration in the ground, these make perfect upgrades to microfiltration systems, which can achieve 90-99% removal of impurities by using efficient setups.

No regular chemical use

Chemicals are used to clean components and membranes The ultrafiltration process is in and of itself (a mechanical, pressure driven membrane-based separation) does not require any chemicals. This helps to prevent altering the flavor or odor, and also reduces the operational cost.

Energy consumption is low.

In comparison to reverse osmosis and nanofiltration, ultrafiltration is less energy consumption due to its lower operating pressure demands. Household systems can often run on normal inlet pressure, while larger industrial/commercial setups only need high-pressure pumps for adequate pressure. Systems can also be powered by 220V to 480V. 50-60Hz options for power.

Applications of the Ultrafiltration Process

Ultrafiltration’s versatility is evident in industrial, municipal and commercial/household environments.

Industrial Applications

In industrial settings it can solve water-related issues. Electronics companies use it to treat the water used for ultra-pure production and safeguarding downstream equipment. Food processors depend on it to decrease the COD (Chemical Oxygen Demand) levels to ensure compliance and reuse of water, which reduces costs. Chemical plants employ it to purify water to prevent scaling and prolonging the lifespan of machines.

Municipal Applications

Municipal applications are focused on water safety for the public and efficiency of resources. It improves the quality of tap water by eliminating pathogens and algae traditional methods fail. In wastewater facilities they upgrade treatment in order to create reclaimed water for urban greening, irrigation as well as industrial cooling.

Commercial/Household Applications

For household and commercial use It offers practical solutions for both residential and commercial use. Hotels employ it for clean drinking water in direct contact as well as malls employ it to clean the pool water. Ultrafiltration purifiers at home eliminate odors and bacteria, keeping the essential minerals for use by the family.

Conclusion

Ultrafiltration, a crucial membrane-based water treatment technology that uses pressure-driven porous separation (0.01-0.1mm membranes) to get rid of pathogens, bacteria and solids while conserving minerals. Its system includes specialized membranes (PVDF, PAN, PES), scalable modules and auxiliary gear; the process has three stages: pre-treatment, core filtration and post-treatment/maintenance. It is beneficial to industry, public health as well as communities, and is applicable to the municipal, industrial and household situations. For efficient, reliable ultrafiltration solutions, Molewater’s Water Treatment Plant, which is designed to fit any scale–is the best option.