Pharmaceutical antibiotic wastewater presents unique challenges: high COD (10,000-80,000 mg/L), biological toxicity, recalcitrant compounds and pH fluctuation between 4.0-10.0 with antibiotic residues potentially harming ecosystems. Traditional physical-chemical methods often fail to completely degrade antibiotic residues while strict environmental regulations dictate compliant discharge; biological wastewater treatment offers targeted solutions to address all these pain points–here are its top 5 benefits!

What Is Biological Wastewater Treatment?

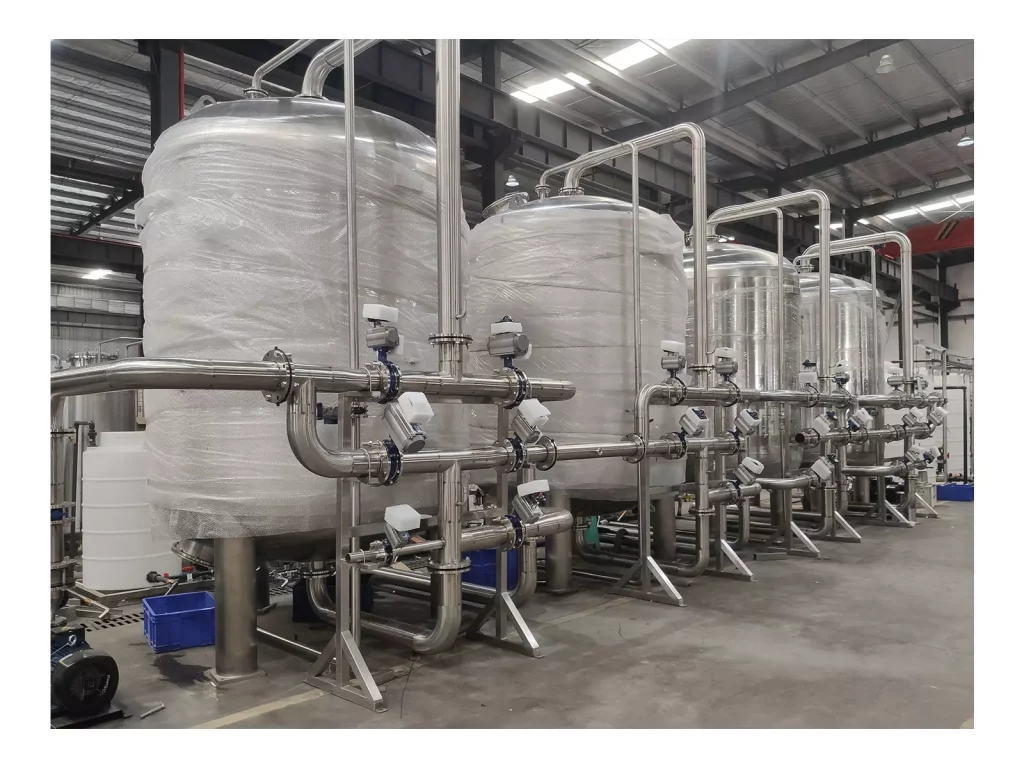

Biological wastewater treatment consists of specially picked organisms (bacteria, fungi, and archaea) that degrade high-concentration organics, antibiotics, and toxic intermediates in pharmaceutical wastewater. This makes an opposite to chemical treatment that only transfers or slightly chances the contaminants, thereby basing on the microbial metabolism to render harmful substances as carbon dioxide and water into various other harmless compounds. This is to emulate the natural purification mechanism but designed, on a large scale, for industrial toxic wastewaters.

- Vital component of Pharmaceutical ETP: Operates in balance with beneficial influences from a variety of pretreatment steps, such as Fenton/ozone oxidation and post-treatment technologies (MBR, RO) for meeting strict regulations of pollution.

- Differentiated for the pharmaceutical industry challenges:>High COD (10,000-80,000 mg/L), antibiotic-induced biological inhibition, and pH (4.0-10.0) fluctuations.

- Multiple-stage techology interface: Anaerobic (UASB/EGSB), aerobic SBR and biological contact oxidation, and biofilm systems stack up the capacity for treating varied and complex water quality.

With their applications in a generic practical medium-sized pharmaceutical plant treating 100,000 L antibiotic wastewater/day, the technical unit of their synergy scheme can now get over 80% of COD removal with cost savings in chemicals of over 30%. Close to one-half of reciprocating waters can be put to the purpose of cooling, slashing the operations-by $20,000 annually while keeping up with stringent environmental regulations.

1. Advanced Degradation of High-Concentration Organic Pollutants

The main achievement of biological treatment is removing high organic loads ethanol, which is made particularly effective by nature against tenacious pollutants. The joint treatment of highly loaded complexing pharmaceutical antibiotic drainage aggravated by the physical methods of bacteria with aerobic biological mechanisms (anaerobic UASB/Upflow Anaerobic Sludge Bed and EGSB/Expanded Granular Sludge Bed reactors) for natural discarding of organic growth to dissipate in carbon dioxide, water, and biomass completes the work, contributing to a 80%-plus degradation of COD where physical-chemical methods only transfer pollutants. Complete removal of solid waste was improved upon by the interrelated MBR membrane bioreactor, Molewater, in making sure that the COD in the effluent would not rise above 300 mg/L-compliance with stringent discharge standards. This means complete removal of pollutants by the pharmaceutical industries devoid of residues for toxins in the environment.

2. Cost Effectiveness and Energy Recovery

Pharmaceutical enterprises managing large-scale wastewater treatment processes recognize the significance of cost effectiveness and energy recovery as two core benefits for successful operations. Biological treatment offers a sustainable alternative to costly chemical-intensive technologies like advanced oxidation or membrane separation systems that rely on expensive chemicals and high energy input, thus significantly cutting operational costs and decreasing operational expenses. An anaerobic stage also generates methane-rich biogas that can be recovered for heating or power generation, offsetting energy expenses. Longer-term, it reduces costs associated with chemical procurement, disposal, and equipment maintenance. When applied to high salinity antibiotic wastewater treatment systems, biological treatment combines seamlessly with evaporation crystallization for cost efficiency while remaining budget friendly – an economical solution suitable for sustained operations.

3. Capability of Responding to Varying Water Quality

Pharmaceutical wastewater can vary considerably between production batches in terms of pH levels, pollutant concentrations, and antibiotic loads. To remain flexible to these changes, strong adaptive capabilities should be in place in order to adapt accordingly. Biological treatment systems such as SBR processes adapt readily to these fluctuations. Microbial communities within the system adjust their metabolism in response to shifting organic loads, thus preventing sudden drops in treatment effectiveness. Fenton or ozone oxidation pretreatment can help address antibiotic-induced biological inhibition by increasing biodegradability (B/C ratio from 0.15 to 0.42) for stable biological system operation, eliminating frequent adjustments needed to operate at maximum compliance with production-related water quality variations. This also simplifies maintenance complexity while assuring compliance.

4. Environmental Friendliness & Reduced Secondary Pollution

Of the many advantages of biological treatment, its sustainability is significant. It does not involve intensive use of chemical coagulants or oxidants, which generate a toxic sludge treatment waste. Hence, the influence of secondary pollutants almost becomes null under this case, as sludge is minimally toxic and easier to treat; some possible sludge treatments include composting. The most crucial thing is antibiotic deterioration, the cure for antibiotic-resistant bacteria, which have been increasing in water bodies by extensive antibiotic pollution. Protecting the soil and aquatic environment, this is the heart of the work related to green production in the industry, thereby helping pharmaceuticals to be environmentally friendly and practice their corporate social responsibility.

5. Integration with Advanced Water Reuse Processes

Biological treatment for sewage clearance provides the foundation for water reuse, a strategy in high demand by water-short pharmaceutical companies. Such effluent can receive further polishing after biological treatment—using advanced processes such as nanofiltration (NF), reverse osmosis (RO), or activated carbon adsorption. This synergy creates a rather higher standard of reclaimed water for use in production cooling, lowering water demand for equipment cleaning, and irrigation at the same time. Such strategies ultimately need much less fresh water. Molewater designs custom solutions to combine biological treatment, intensive membrane selection, recirculated water systems, and high-efficiency disinfection, and cost reduction in the overall venture water supply. In conclusion, in line with the lean and green plant model, resource conservation leads not only onto operational sustainability but also towards the conservation of water resources as far as pharmaceutical firms are here concerned in a water-scare world.

Biological wastewater treatment offers an amazing list for the pharmaceutical antibiotics wastewater industry—efficient pollutant degradation, cost savings, adaptability, environmental safety, helping water reuse. It directly answers industry’s core demons by looking after the compliance, economics, and sustainability-tied parameters. Molewater, through tailored construction of biological treatment systems using UASB/EGSB, SBR, MBR technologies, offers vivid solutions to pharmaceutical facilities worldwide. Contact Molewater today and benefit from these advantages while achieving discharge compliance and financially and environmentally sustainable operations.